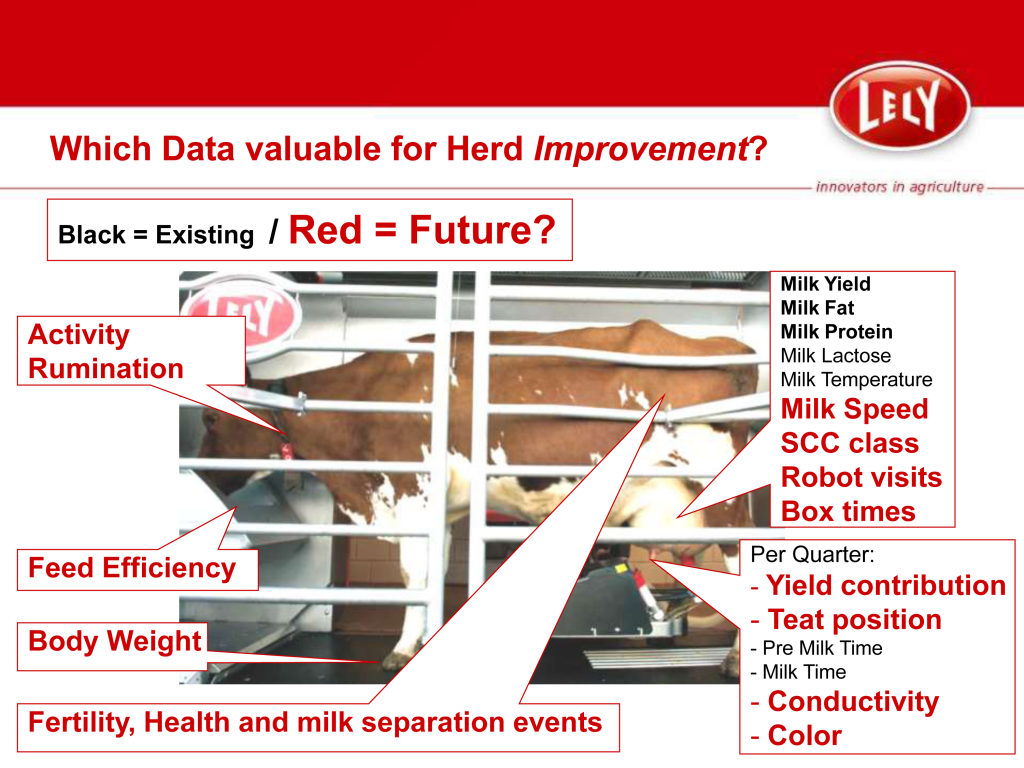

Over the past few years the management and genetic sides of the dairy cattle industry have been handed a huge data opportunity. One example comes from Lely who report that their robotic system can capture more than 120 different values per cow per day. Sounds excessive doesn’t it? For some breeders that number is beyond comprehension. However, before offering a final assessment on volume of data, let’s dig deeper.

Dairy farm operators know very well the challenges resulting from high feed cost and narrow margins. But they do not have the numbers to get down to the exact profit at each individual cow level. Do they breed Bessie back? If so what should she be breed to improve her? Or is she the next cow to be culled based on revenue generated less expenses? The challenge has been that managing Bessie has always been in hindsight and what is needed is real time management of her situation. Add to that the fact that wages and labor laws in many developed countries are causing breeders to rethink the degree of automation to apply to their operations. Many sensors already exist for measuring and monitoring cows and many are in the process of coming to market. It all comes down to having the numbers to manage, breed, feed and farm. There are many management considerations that discerning breeders should reflect on as they plan for future success in the dairy cattle industry.

Eight Numbers for Better Cow Management Decisions

- Animal Weight – Ways of capturing a cow’s weight available many more factors can be added to what is known on an individual cow basis. Factors like feed intake, loosing or gaining weight and individual cow profit per day for the past week come quickly to mind. These sensors also allow for monitoring of negative energy balance determined by body weight changes and milk solid ratios.

- Rumination – Having a healthy rumen is paramount to having a productive profitable dairy cow. Since it is not possible to determine DMI (Dry Matter Intake) on an individual cow basis, rumen activity sensors are used to endure that a cow’s digestive system is functioning well. The sensors also allow for consistent monitoring of feed delivery to ensure feed truck operators are doing their job.

- Components / Milk Quality – Many on-farm systems can now capture fat %, protein %, lactose %, milking time, SCC, Conductivity and color of the milk at every milking (SCC is not equal to conductivity and color of the milk indicates mastitis alerts as well). These numbers and some of the relationships one to another give important information on both a daily and lactation basis. Knowing about problems immediately is by far the best way to address them. Wouldn’t all breeders like to be able to know about a pending SCC spike and address it immediately?

- Temperature – is captured as either milk temperature or can be electronically read from a device such as a bolus in the rumen. The milk temperature is taken 2 – 4 times per day and is a start. However having an internal device provides for real time cow management. The obvious use of temperature changes is general cow health throughout lactation in order to detect differences from normal. Knowing a cow’s temperature after calving has been found to be very useful in getting her off to the right start. New to management tools could be monitoring a cow’s temperature, hour by hour, during her heat period. Breeding at exactly the right time is being studied and preliminary results are showing greatly increased pregnancy rates when body temperature is considered. Think how beneficial it would be to have a 65% conception rate instead of a 35-40% rate.

- Heat Detection – In addition to the idea, just mentioned, of breeding by temperature during heat, there are many systems working successfully that record cow movement and thus signal to breeders that a cow is more active and should be closely observed for being in heat. Yet another device is one that measures hormone levels signalling an on-coming heat (Read more: Better Decision Making by Using Technology). Just think of the savings in labor, drugs, vet costs, semen, extra days spent in dry pens and days of lower milk production at the end of lactation if conception rates could be 70% or higher in cows and 85% or higher in heifers.

- Milk Yield Every Milking – On a milking to milking basis nothing is more important than to know if a cow has produced to the expected level. All automated milking systems can do that and so breeders with those systems have a very important tool at their disposal. Cows falling below expectation are highlighted for attention by the herdsman either immediately or on a list that can be reviewed at any time.

- Listings – Every automated system is capable of generating lists and graphs from the data captured. When a breeder first gets an automated system, they use the lists to find the problems or underperforming cows. However after a time breeders also find the reports to be very beneficial for setting goals for their cows and herd. A list can be as simple as knowing which cows, in a robotic herd, have not been milked. Or are they sick or lame? No matter what, the herdsman has a reason to find the cow and investigate. Breeders not only benefit from knowing what goes on in their own herd but the equipment providers are able to use the data from across herds in establishing benchmarks. And it is not only the breeder that benefits, his veterinarian and feed advisor now have information that they can use to make better recommendations.

- Heifers – The heifer herd is the forgotten part of the dairy herd (Read more: Should you be raising your own heifers?). Automated calf feeding systems are now being used successfully. Many of the devices mentioned above, for cows, can be used for heifers as well. Just think of what the saving would be if age at first calving could be reduced by 3-4 months, $400 saved per heifer raised amounts to $20,000 savings per year in a 100 cow herd.

Numbers to Breed Better Cows

Having better management tools is only 50% of the success equation. The other half is breeding better cows. The data that would separate the best from the rest is a long and growing list.

- Milk Yield Every Milking – The most accurate lactation production is when a weight from every milking is known. By having a weight captured at every milking, a genetic index could be calculated for a bull’s daughters peak production and persistency of production. Knowing such details may in fact help breeders determine the performance pattern that they want from their cows.

- Components / Milk Quality – Here as well, having more observations will increase the accuracy of genetic indexes in order to breed cows that produce the milk that processors and consumers demand.

- Milking Speed – The current genetic indexes are calculated using breeder assigned subjective rating. Fast, average or slow. Automated milking systems are now capable of capturing milking times. As more herds move to automated systems it will be possible to know if a bull’s daughters take 30 seconds less or 30 second more to milk. Time to milk determines the number of cows per robot or the size of the parlor. Milking speed is not consistent throughout the life of a cow and has variations even in the lactation. More over the robot gives an honest measurement which is not affected by the fear of the cow for the milking appraiser.

- Adaptability / Temperament – Breeder know that not all cows are equal when it comes to be handled, milked and cared for. Using data from automated systems it will, in the future, be possible to produce genetic ratings for how bull’s daughters work within automated systems, their temperament, and other factors that breeders see as being necessary.

- Reproduction / Fertility – Currently the data we have on cows, bulls and embryos are stored on many different databases. Bringing that information to a linked data system, studying it and then developing genetic bull rankings could well be a significant development when it comes to increasing the reproductive performance of dairy cattle.

- Feed Efficiency – One of the most read articles that The Bullvine routinely produces is the one listing sires that will produce the most feed efficient cows (Read more: Feed Efficiency: The Money Saver and 50 Sires that will Produce Feed Efficient Cows ). Bullvine readers want to have genetic evaluations for feed efficiency. For some Bullvine readers sire rankings cannot come too quickly. Research is currently underway to determine the relationship between feed efficiency and other genetic indexes. However if feed intake data could come from automated on-farm systems it would be a big step forward.

- Lameness / Mobility – On a herd and industry basis, mobility issues are a big financial drain due to animal cull, lost production and added costs. Breeders know that cows that avoid lameness, that are able to easily get to the feed bunk or pasture and that spend the majority of their time resting, are the kind of cows that make the most profit. With more complete data from automated systems and with perhaps additional sensors it will someday be possible to have genetic indexes for mobility.

The Bullvine Bottom Line

The definitive statement, when it comes to information and data on dairy farms, is that we have currently only scratched the surface. Definitely much more data from automated on-farm systems will soon be available for breeders to use to operate their dairy enterprises and to select their sires. Decisions made by dealing with the exceptions or past performance are old concepts. What is needed is more condensed and focused information and data to manage with on a real time basis. More data from automated data capture systems can and will make this a better industry. Let’s welcome in the future.

Get original “Bullvine” content sent straight to your email inbox for free.

Leave a Reply

You must be logged in to post a comment.