Is now the right time to lock in milk prices? Learn essential strategies for dairy farmers to manage risk and boost profits.

Summary: The volatility of milk prices has many dairy farmers wondering, “Is now the time to lock in milk prices?” With Class III milk contracts trading over $22 per hundredweight (cwt.), the potential for risk management through hedging becomes enticing. Supply chain disruptions, adverse weather conditions, increased demand, global markets, and inflationary pressures drive these historical price levels, creating challenges and opportunities. Class III prices have historically varied between $13 and $16 per cwt Throughout the last decade. Locking in milk prices may secure a farmer’s financial future, enabling them to stabilize income even if market prices drop. Consulting with a broker can provide the necessary guidance to navigate these complexities and help make more informed decisions in this unpredictable market. Dairy industry Locking in milk prices isn’t just about stabilizing income; it’s a strategic move to manage risk in an unpredictable market.

- Current Class III milk contracts are trading over $22 per hundredweight (cwt.), presenting an opportunity for risk management through hedging.

- Factors driving these historic price levels include supply chain disruptions, adverse weather conditions, increased demand, global markets, and inflationary pressures.

- Historically, Class III prices have varied between $13 and $16 per cwt. Over the last decade.

- Locking in milk prices can help farmers stabilize their income even if market prices drop.

- Consulting with a broker is essential for navigating these complexities and making informed decisions.

- Locking in milk prices is a strategic move to manage risk in an unpredictable market.

Are you aware milk prices have reached historic levels, hitting over $22 per hundredweight (cwt.) for forthcoming contracts? This increase creates a unique challenge and opportunity for dairy producers and experts. With such high futures market prices, the question arises: Is this the best time to lock in milk prices to protect gains and limit risk? Let’s examine why this is an important issue and possible solutions. Class III milk futures market prices are at historically high levels. This creates a strategic opportunity for farmers, allowing them to hedge their risks and take control of their earnings while proving their critical role in controlling the rise.

What’s Driving the Unprecedented Surge in Milk Prices?

Let’s look at the present state of milk pricing on the futures market. According to the latest sources, Class III milk futures for the following months—particularly September, October, and November—are trading at about $22 per hundredweight (cwt). This historically uncommon level indicates potentially good circumstances for dairy producers, providing a ray of light in an otherwise difficult market. This pricing increase can potentially deliver significant advantages to the sector, giving grounds for hope.

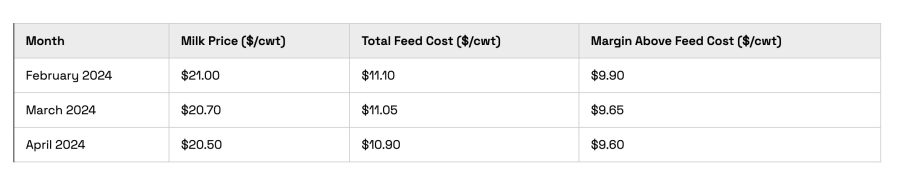

Recent market data indicates a significant gain over the previous quarter. A few months ago, Class III milk prices hovered around $18-$19 a cwt. This growing tendency has raised eyebrows and sparked hope across the sector. Recent research suggests that numerous reasons might be driving these very high prices.

First and foremost, supply chain disruptions have had a considerable impact. Post-pandemic recovery efforts have raised transportation costs and delays, affecting every aspect of the dairy supply chain. Adverse weather conditions in vital dairy-producing areas have reduced milk production levels.

Demand has also shifted. The reopening of restaurants and food services has increased dairy demand, particularly cheese and other Class III milk goods. Global markets can influence pricing. For example, increasing export demand owing to lower supply in other key exporting nations such as New Zealand has boosted US milk prices.

Furthermore, inflationary pressures raise input costs for feed and other agricultural necessities, causing farmers to seek higher prices to remain profitable. Given the present economic context, it is advisable to consider locking in these prices as a buffer against any decline.

These reasons contribute to the present high price of Class III milk contracts. Understanding these variables allows dairy producers to better judge whether to lock in milk prices. This information provides them with viable tactics for managing the rise, ensuring they are ready for market situations.

Why Understanding Historical Context is Crucial

To completely understand the present rise in milk costs, it is necessary to consider the historical backdrop. Monitoring past averages better explains why current situations offer ample opportunity. Historically, Class III milk prices have been quite volatile. For example, prices have consistently varied between $13 and $16 per hundredweight (cwt.) throughout the last decade, with noticeable peaks and troughs.

One of the most essential peaks happened in September 2014, when prices reached a record $24.60 per cwt. In May 2020, however, prices fell to roughly $12.14 per cwt due to market disruptions caused by the COVID-19 epidemic. These changes emphasize the dairy market’s inherent risks and uncertainties.

We’re approaching record highs, with futures trading at $22 per cwt. When compared to the average price of about $16 per cwt. Today’s numbers are undoubtedly the most notable over the previous decade. This background highlights the possible risk-management benefits of locking in pricing today. Securing these relatively high prices may help protect against any market downturns.

Furthermore, the present market is formed by several other variables, including supply chain interruptions and growing global demand, which add another element of unpredictability. Given these dynamics and the historical background, locking in milk prices now might be prudent to secure your financial future.

Locking In Milk Prices: Understanding the Basics

Look at locking in milk pricing and how it affects a farmer’s revenue.

Imagine you are a dairy farmer. You’re concerned about market volatility, which might make your income uncertain. Locking in pricing via the futures market enables you to establish your milk price ahead of time, decreasing unpredictability.

Here’s an example:

- Scenario 1: You set a price of $22 per hundredweight (cwt) for your milk. Later, if the market price falls to $18 per cwt, you will still get your locked-in price. You make more than the current market worth.

- Scenario 2: If the market price climbs to $25 per cwt, the locked-in price will result in a lower payout. However, this situation allows you to prevent the possible revenue loss if prices unexpectedly collapse.

- Scenario 3: The effect is minor if the market price remains close to your locked-in pricing. You enjoy peace of mind knowing that your income will not change much.

Understand that this is not risk-free. While locking in prices may protect against falls, it may also result in losing out on more considerable earnings if market prices rise. Consulting with a broker may help you navigate these waters more successfully.

The Strategic Advantages of Locking in Milk Prices

Locking in milk prices has various significant benefits, notably in risk management and financial stability. Farmers may protect themselves from market volatility by getting a predetermined product price. This assurance is helpful regarding budgeting and financial planning.

Consider the situation of John, a dairy farmer in Wisconsin. John set his milk rates at $20 per cwt for the second half of 2022. When the market price fell to $18 per cwt due to unanticipated global economic events, such as a sudden drop in demand or an increase in production costs, John could retain his income expectations. “Locking in prices gave me peace of mind,” John said. “I didn’t have to worry about the market fluctuations impacting my bottom line.”

Industry analysts share this attitude. Agriculture Secretary Tom Vilsack states, “Farmers who lock in their prices can navigate uncertain markets with greater confidence.” They are protected from sharp price declines and the financial pressure that such changes may cause” [source: USDA Report on Dairy Futures, 2023].

The benefits of these strategies are apparent from the statistics. University of Minnesota research indicated that dairy producers who used price-hedging tactics had a 15% lower revenue volatility than those who did not. This means their income was more stable and predictable, even in a fluctuating market. Furthermore, brokers claim that farmers increasingly turn to these technologies, understanding the protection they bring in an unstable market.

Financial stability is another critical advantage. When dairy farms can better estimate their revenue, making educated choices regarding equipment, feed, and other vital areas becomes more accessible. This stability may result in overall growth and increased agricultural efficiency.

Locking in milk prices gives farmers the tools to better manage risks and provides a solid financial basis for their businesses. Capitalizing on market fluctuations might be a wise step for long-term success.

The Trade-offs and Decisions Behind Locking in Milk Prices

While locking in milk pricing provides stability, it carries several risks and concerns. The most evident danger is the possibility of lost chances. If market prices climb considerably beyond the locked-in rate, farmers will earn less than if they did not hedge. Our last example demonstrated this since a hypothetical upswing resulted in a loss in the futures market.

Another critical issue is the expense of this procedure. Brokers collect costs for each transaction, which may accumulate over time, especially if contracts are often exchanged. For example, with an average brokerage cost of $70 per transaction and each contract needing two transactions, these expenses may significantly reduce prospective earnings. These fees may have a considerable financial effect when applied to many agreements.

However, the value of talking with a broker cannot be emphasized. Brokers have essential experience and may give strategic advice specific to your circumstance. They guide farmers through the complexity of the futures market, ensuring that they make educated choices. Balancing the costs and advantages of their services is critical—after all, their experience might help you avoid expensive errors.

Finally, determining whether to lock in milk prices requires assessing the risks against the possible benefits. This is not a one-size-fits-all answer. Before making a move, farmers should consider their financial status, market prospects, and risk tolerance. Consulting a broker for tailored assistance will help you make the right option for your farm’s future.

Exploring Alternative Risk Management Strategies

Dairy producers use various risk management measures in addition to futures contracts. Forward contracts, for example, enable farmers to sell their milk at a specified price straight to a buyer. This strategy provides price stability while avoiding the complicated dynamics of the futures market.

Another alternative is to employ future options that provide the right but not the obligation to sell milk at a specific price. This provides flexibility and a mechanism to hedge against adverse price fluctuations while still having the opportunity to profit from positive developments.

Insurance policies tailored explicitly for dairy producers are also available. These policies, such as the USDA’s Dairy Income Protection (DRP) program, may protect against sudden declines in milk prices or income, adding an extra degree of protection.

Exploring these different tactics may provide a more complete risk management strategy, enabling farmers to choose the best option based on their conditions and risk tolerance.

The Bottom Line

The basics of locking in milk prices via the futures market provide dairy producers with a possible route to stability in the face of volatile market circumstances. Whether the USDA announces an unexpected fall, a surprising upsurge, or market stability, the price-locking system acts as a risk-mitigation tool, ensuring predictable returns.

With Class III milk prices near record highs, the current market may be ideal for preemptive steps. The noted high prices provide a unique chance to lock in rates that may protect against future downturns. Partnering with a qualified broker can help you navigate the intricacies and make educated choices corresponding to your company objectives.

As you decide on the next move, remember the dairy market’s long-term tendencies and future changes. Can these high prices be maintained, or is a correction on the horizon? The answers will define your plan and may make all the difference in ensuring your farm’s profitability and stability in the volatile world of dairy farming.

Learn more:

- Heads Up, Dairy Farmers: Low Feed Prices Won’t Last – Lock Them In Now!

- Is the Summer Heat Finally Over? Dairy Farmers See Milk Production Stabilize, but Challenges Remain!

- Big Milk Checks and Low Feed Costs: A Profitable Summer for Dairy Producers

Join the Revolution!

Join the Revolution!

Bullvine Daily is your essential e-zine for staying ahead in the dairy industry. With over 30,000 subscribers, we bring you the week’s top news, helping you manage tasks efficiently. Stay informed about milk production, tech adoption, and more, so you can concentrate on your dairy operations.

Join the Revolution!

Join the Revolution!