Latest News

Dairy’s Big Break: How New Snap Legislation Could Reshape Your Bottom Line

New SNAP bill could put $2.4B/year in dairy farmers' pockets while fixing America's nutrition gap. Here's how to cash in. EXECUTIVE SUMMARY: The bipartisan Dair […]Dairy’s Golden Calf Rush: $1,000+ Crossbreds Reshape Farm Economics

$1,000+ calves rewrite dairy profits! Why beef shortage means YOUR herd is now a goldmine. EXECUTIVE SUMMARY: Record-high calf prices ($1,000+/head) are reshapi […]Milk Tsunami Ahead: USDA Exposes 2025 Price Crash Triggers

USDA warns of 2025 dairy profit meltdown: Milk prices crash $1.95/cwt in 4 months. Discover survival tactics for the coming storm. EXECUTIVE SUMMARY: The April […]84% Chinese Tariffs Slam US Dairy: Why Whey & Lactose Exports Face Crisis

84% Chinese tariffs slam US dairy exports. Prices plunge, markets scramble. Can producers pivot fast enough to survive? EXECUTIVE SUMMARY: Escalating US-China t […]CME Dairy Market Report: April 10, 2025 – Cheese Blocks and Butter Prices Surged Despite Bearish USDA Outlook

Cheese and butter prices surge despite bearish USDA forecast and 84% China tariffs. What's driving this contradictory market behavior? EXECUTIVE SUMMARY: CME da […]

More News

- Dairy’s Perfect Storm: Market Mayhem Reshapes Farm Profitability in 2025

- Udder Health: Small Changes That Make a Big Difference in Dairy Profitability

- H5N1 Crisis Hits 1,000 U.S. Dairy Herds: California Epicenter and Nevada’s New Viral Threat Demand Immediate Action

- Trump’s $998-A-Day Migrant Fines: Is it a Death Sentence for America’s Dairy Industry?

- U.S. Dairy Farmers Unlikely to Cash in on Chinese Demand

- Trade War Redux: Why Milk Prices Already Dropped 12% Before Tariffs Hit

- CME Dairy Market Report – April 9, 2025: Cheddar Barrel Prices Surge on Strong Buying Interest; Dry Whey Declines Notably Amidst Generally Firming Dairy Futures

- GLP-1 Weight Loss Drugs Reshape Dairy Demand: The $35,000 Question No Dairy Farmer Can Afford to Ignore

- Cabot Creamery Butter Recall

- H5N1 Crisis One Year Later: What Dairy Farmers Need to Know

Top News Posts from Past Week

- Inbreeding Alert: How Hidden Genetic Forces Are Reshaping Your Dairy Herd’s Future

- Trump’s $998-A-Day Migrant Fines: Is it a Death Sentence for America’s Dairy Industry?

- $4,000 Heifer Shock: Replacement Heifer Prices Reach Record Territory

- Viral Ground Zero: Austria Slams Borders Shut as FMD Threatens Europe’s Dairy Industry

- Mega-Dairy Revolution: Inside the World’s 10 Largest Dairy Farms

- Top 100 TPI Sires: April 2025

- Kobama-Farm Xmas Delta-Lambda Crowned Grand Champion at 50th Central Japan Holstein Show

- Calves for a Cause 2025: Dairy Industry’s $170K+ Legacy Shines at Canadian Dairy XPO

- April 2025 US Holstein Evaluations: Genetic Base Change Reshuffles Rankings While Elite Bulls Hold Strong

- From Farm to ‘Shark Tank’: Connecticut Dairy Farmer’s Eco-Friendly Innovation Takes the Stage

Feature Articles

Revolutionary Colostrum Protocol Adding $500 Per Heifer to Your Bottom Line

Are you discarding liquid gold? Discover how extended colostrum feeding adds $500 per heifer while slashing treatment costs and boosting lifetime milk. E232 Rev […]2024 Holstein Canada Master Breeders: Excellence in Balance, Breeding, and Legacy

19 Canadian dairy farms earn elite 2024 Master Breeder status—discover the secrets behind their balanced breeding success! E230 2024 Holstein Canada Master Bree […]Dad at 80: How Murray Hunt Revolutionized Canadian Dairy Genetics

At 80, Murray Hunt’s dairy genetics innovations still shape global herds—meet the visionary who made science the farmer’s ally. E229 Dad at 80: How Murray Hunt […]When Faith Meets Farming: Mark Yeazel’s Amazing Journey from Holstein Breeder to Tanzanian Dairy Missionary

From elite Holstein breeder to Tanzanian missionary: How Mark Yeazel trades show rings for orphan care through dairy farming. E228 When Faith Meets Farming: Mar […]BLACK HIDE BLINDNESS: Why Breeding Only for Color is Destroying Your Dairy-Beef Profits

Black hide obsession is costing you thousands. Those cheap Angus straws? Economic suicide. Discover why color alone won't save your beef-on-dairy profits. E227 […]

More Articles

- Stud Wars: April 2025 – The Genetic Force Awakens

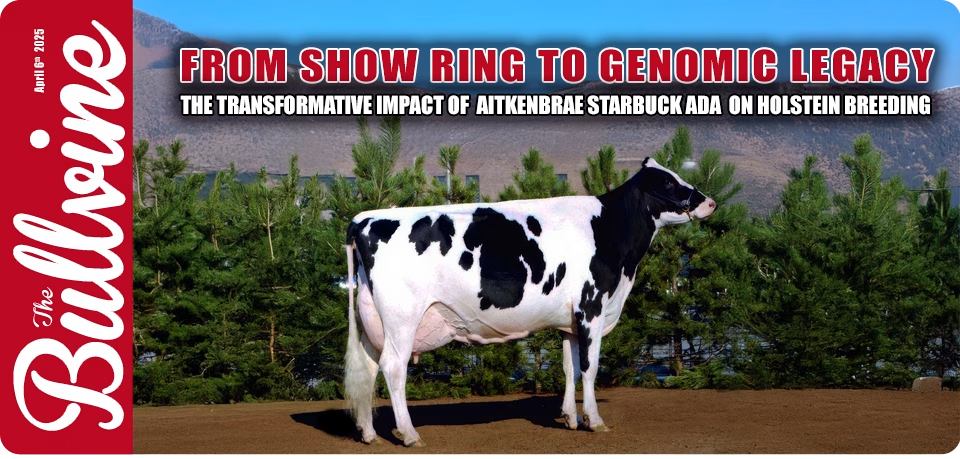

- From Show Ring to Genomic Legacy: The Transformative Impact of Aitkenbrae Starbuck Ada on Holstein Breeding

- Spring Pasture Powerplay: Balancing Grazing Efficiency with Milk Component Goals

- Unlocking Dairy Robot Financing: How Smart Farmers Are Funding Their Automated Future

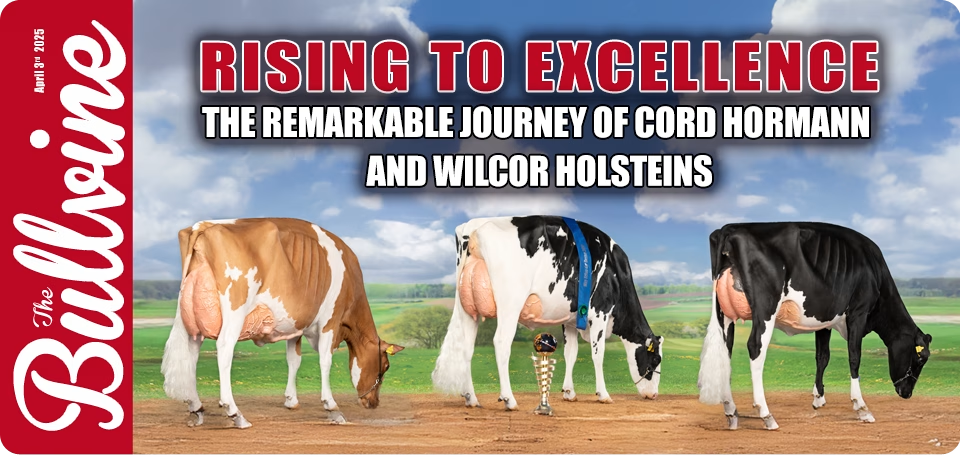

- Rising to Excellence: The Remarkable Journey of Cord Hormann and Wilcor Holsteins

- April 2025 Global Holstein Evaluations: New Leaders Emerge as Genetic Progress Accelerates Worldwide

- Northeast Spring National Holstein Show 2025

- When Cows Were Kings: Revisiting Carnation’s Golden Age of Dairy Breeding

- BEEF-ON-DAIRY REVOLUTION: Former Dairy Farmers Finding Gold in the Beef Market Corporate Giants Overlooked

- BST Reapproval: The Key to Unlocking Dairy Sustainability

Top Feature Articles from the Past Month

- Top 15 Best Milk Brands in the USA: Unveiling the Cream of the Crop

- Northeast Spring National Holstein Show 2025

- 10 Sires To Breed The Next World Dairy Expo Grand Champion

- The Cow That Built an Empire: Comestar Laurie Sheik’s Unstoppable Genetic Legacy

- Why Donald Trump Hates Canada’s Dairy Supply System

- CAPTAIN: The Bull That Rewrote the Rules for Modern Breeding

- Making Dreams Come True: The Journey of Tom & Kelli Cull

- The $4,300 Gamble That Reshaped Global Dairy Industry: The Pawnee Farm Arlinda Chief Story

- From Pasture to Powerhouse: The GenoSource Story

- Bull in a China Shop: How Juan Moreno Turned the Dairy World Upside Down

- Revolutionary Colostrum Protocol Adding $500 Per Heifer to Your Bottom Line

-

Revolutionary Colostrum Protocol Adding $500 Per H…

Andrew Hunt Apr 11, 2025Are you discarding liquid gold? Discover how extended colostrum feeding adds $500 per heifer while slashing treatment costs and boosting lifetime milk. E232 Revolutionary Colostrum Protocol Adding $500 | RSS.com Your current calf feeding program may be limiting your profitability by up to $5… Read More - 2024 Holstein Canada Master Breeders: Excellence in Balance, Breeding, and Legacy

-

2024 Holstein Canada Master Breeders: Excellence i…

Andrew Hunt Apr 10, 202519 Canadian dairy farms earn elite 2024 Master Breeder status—discover the secrets behind their balanced breeding success! E230 2024 Holstein Canada Master Breeders: Excelle | RSS.com The Holstein Canada Master Breeder shield represents the pinnacle of achievement in dairy cattle breeding – a… Read More

- Dad at 80: How Murray Hunt Revolutionized Canadian Dairy Genetics

-

Dad at 80: How Murray Hunt Revolutionized Canadian…

Andrew Hunt Apr 9, 2025At 80, Murray Hunt’s dairy genetics innovations still shape global herds—meet the visionary who made science the farmer’s ally. E229 Dad at 80: How Murray Hunt Revolutionized Can | RSS.com My father Murray Hunt at 80: The quiet visionary who transformed Canadian dairy breeding with scientific… Read More

- When Faith Meets Farming: Mark Yeazel's Amazing Journey from Holstein Breeder to Tanzanian Dairy Missionary

-

When Faith Meets Farming: Mark Yeazel’s Amazing Jo…

Karen Hunt Apr 9, 2025From elite Holstein breeder to Tanzanian missionary: How Mark Yeazel trades show rings for orphan care through dairy farming. E228 When Faith Meets Farming: Mark Yeazel’s Amazi | RSS.com You know what gets me? Stories about dairy farmers who entirely flip the script on their careers. And man,… Read More

- BLACK HIDE BLINDNESS: Why Breeding Only for Color is Destroying Your Dairy-Beef Profits

-

BLACK HIDE BLINDNESS: Why Breeding Only for Color…

Andrew Hunt Apr 8, 2025Black hide obsession is costing you thousands. Those cheap Angus straws? Economic suicide. Discover why color alone won't save your beef-on-dairy profits. E227 BLACK HIDE BLINDNESS: Why Breeding Only for C | RSS.com You're riding a fading trend, and your bottom line will pay the price. Since… Read More

- Stud Wars: April 2025 - The Genetic Force Awakens

-

Stud Wars: April 2025 – The Genetic Force Awakens

Andrew Hunt Apr 7, 2025Sexing Tech's 40% NM$ empire vs ABS's 68% polled coup – the dairy genetics galaxy will never be the same. E225 Stud Wars: April 2025 – The Genetic Force Awa | RSS.com The battle for Holstein genetic supremacy rages on in a galaxy not so far away. As we unveil the April 2025 sire share analysi… Read More

- From Show Ring to Genomic Legacy: The Transformative Impact of Aitkenbrae Starbuck Ada on Holstein Breeding

-

From Show Ring to Genomic Legacy: The Transformati…

Andrew Hunt Apr 6, 2025How one unassuming cow born in rural Ontario revolutionized Holstein genetics worldwide, bridging show ring glamour with genomic science. E222 From Show Ring to Genomic Legacy: The Transfo | RSS.com Do you know what amazes me about the dairy world? How a single cow can change everything. That… Read More

- Spring Pasture Powerplay: Balancing Grazing Efficiency with Milk Component Goals

-

Spring Pasture Powerplay: Balancing Grazing Effici…

Andrew Hunt Apr 5, 2025Spring pastures can slash profits—discover how to protect your milk check with innovative grazing strategies. E221 Spring Pasture Powerplay: Balancing Grazing E | RSS.com So, we're heading into that critical time of year again when dairy farmers across the Northern Hemisphere face one of thei… Read More

- Unlocking Dairy Robot Financing: How Smart Farmers Are Funding Their Automated Future

-

Unlocking Dairy Robot Financing: How Smart Farmers…

Andrew Hunt Apr 4, 2025Losing $500/day without dairy robots? Discover financing hacks boosting milk yields 9% & slashing labor 28%—before your herd falls behind. E220 Unlocking Dairy Robot Financing: How Smart Fa | RSS.com Have you been eyeing those sleek robotic milking systems but can't figure out how to make… Read More

- Rising to Excellence: The Remarkable Journey of Cord Hormann and Wilcor Holsteins

-

Rising to Excellence: The Remarkable Journey of Co…

Karen Hunt Apr 3, 2025From a 16-cow tie-stall to international glory: How Cord Hormann built Wilcor Holsteins into Germany's elite breeding program through vision and patience. E219 Rising to Excellence: The Remarkable Journey | RSS.com Cord Hormann accepts the prestigious Grand Champion trophy for O Katy at the… Read More

Tanbark Trail

Northeast Spring National Holstein Show 2025

March 31st, 2025 @ Hamburg, NY E217 Northeast Spring National Holstein Show 2025 | RSS.com The New York Spring Holstein Show, judged by Ryan Krohlow, showcased exceptional dairy cattle across multiple age divisions. The competition featured remarkabl […]Is Erbacers Snapple Shakira One of the Greatest Show Cows of All Time?

Uncover why Erbacres Snapple Shakira stands among the top dairy show cows of all time. What makes her excel in the competitive dairy arena? E55 Is Erbacers Snapple Shakira One of the Greatest Show Cows of All Time? From the moment she steps into the […]The Royal Winter Fair 2024 – Jersey

Judge Jeff Sales NTENSE JOEL DELPHIE ETGrand ChampionThe Royal - Jersey Show 2024WEEKSDALE/HI-CALIBER/ROCK ALLEN/F&D BORBA, BREADALBANE, PE c LEACHLAND VIDEO MOCHA K Intermediate Champion The Royal - Jersey Show 2024 WEEKSDALE HOLSTEINS, BRE […]The Royal Winter Fair 2024 – Holstein

Judge Blair Weeks JEFFREY-WAY HARD ROCK TWIGS Grand Champion The Royal - Holstein Show 2024 K. DOEBERIENER, L. BOWEN & PAT CONROY, R&F LIVESTOCK INC, & WALKER DAIRY INC. Grand Champion: Jeffrey-Way Hard Rock Twigs, 1st 4-year-old, K Doebe […]The Royal Winter Fair 2024 – Red & White Holstein

November 4th 2024 Judge: Markus Hehli, Rimbey, AB PREMIUM APPLE CRISP LILLY Grand Champion The Royal - Red & White Holstein Show BUTLERVIEW FARM, CHEBANSE, IL Grand Champion: Premium Apple Crisp Lilly (Apple-Crisp), 1st 5-year-old, Butlerview Far […]

The Bullvine LLC © 2025 | Terms of Use | Community Guidelines | Privacy Policy |

Manage Consent

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.

Functional Always active

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network.

Preferences

The technical storage or access is necessary for the legitimate purpose of storing preferences that are not requested by the subscriber or user.

Statistics

The technical storage or access that is used exclusively for statistical purposes.

The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.

Marketing

The technical storage or access is required to create user profiles to send advertising, or to track the user on a website or across several websites for similar marketing purposes.