Controversial feed boosts milk checks by 15%? New research reveals how whole cottonseed could be your dairy profit game-changer!

Forget what you’ve heard about cottonseed risks—new research published in the Journal of Dairy Science shows strategic WCS feeding can add $2.50/cow/day through smarter milk component management. We break down the real costs, benefits, and implementation secrets your nutritionist isn’t telling you.

The Whole Cottonseed Renaissance: Why Now?

Let’s cut through the barnyard gossip. Whole cottonseed (WCS) has long been the redheaded stepchild of dairy rations, dismissed over gossypol fears and storage hassles. But 2025’s razor-thin margins demand we rethink every input—including this underdog ingredient. A 2025 University of Minnesota trial reveals WCS isn’t just safe at 15% inclusion—it’s a profit rocket when leveraged correctly.

Take Wisconsin’s Schlitzer Dairy, where swapping 5 lbs of soybean meal for WCS last quarter boosted milk fat by 0.3 percentage points. “That’s an extra $1,200 daily on 800 cows,” says owner Greg Schlitzer. “We’re talking life-changing margins in this market.”

But here’s where most farmers stumble: WCS isn’t a magic bullet. It’s a precision tool requiring strategic use. Feed it blindly, and you’ll waste money. Deploy it smarter than your neighbors? That’s how you fund next year’s equipment upgrades.

Why This Matters

Dairy’s current economic landscape demands ruthless efficiency. With milk prices averaging $18/cwt, farmers can’t afford to ignore any edge. WCS’s ability to boost milk fat—often the most lucrative component in value-based pricing systems—transforms it from a fringe feed into a financial weapon.

Key Nutritional Profile:

- 21% fiber: Provides effective fiber without overloading rations.

- 17% fat: Slowly released in the rumen, minimizing biohydrogenation risks.

- 24% protein: A cost-effective protein source compared to soybean meal.

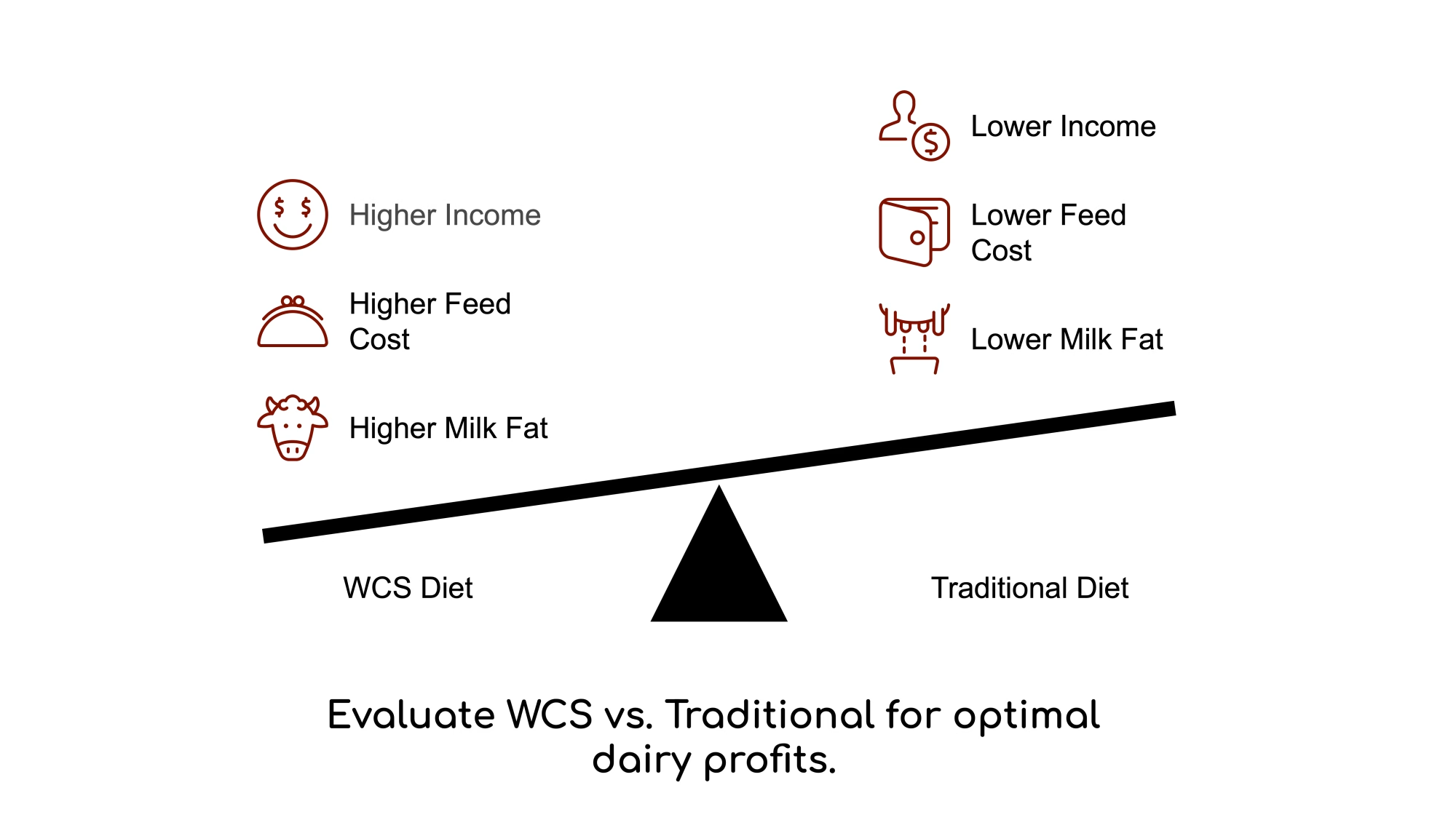

The Money Math: WCS vs. Traditional Inputs

Let’s geek out on numbers. The 2025 University of Minnesota trial compared 15% WCS diets against standard rations using cottonseed hulls + soybean meal. Results?

| Metric | WCS Diet | Control Diet | Difference |

| Milk Fat Yield | 1,210 g/day | 1,100 g/day | +10% |

| Feed Cost/Ton | $315 | $298 | +$17 |

| Income Over Feed Cost | $6.42/cow/day | $5.88/cow/day | +$0.54 |

| Labor Efficiency | 8 min/day | 12 min/day | -33% |

Data from 2025 University of Minnesota trial with 480 lactating Holsteins

Here’s the kicker: While WCS diets cost $17/ton more, the $0.54/cow/day IOFC gain compounds fast. For a 500-cow herd, that’s $98,000 annualized—enough to install a robotic feeder or hire two full-time employees.

But wait—there’s a plot twist. “Farmers fixate on milk price per hundredweight,” says Dr. Linda McMullen, lead researcher. “Smart operators chase components. WCS shifts your milk profile toward what processors actually want.”

What This Means For Your Operation

If your co-op pays premium for fat, WCS becomes a no-brainer. But even in flat-pricing systems, the feed efficiency gains (as seen in FCM/DMI improvements) create hidden value through reduced waste and better resource allocation.

Critical Caveat: Some processors penalize high-fat milk. Check your contract terms before implementation.

Beyond the Hype: Making WCS Work for Your Herd

Storage Hacks for Real Farms

Yes, WCS can heat up faster than a bull in breeding season. But Indiana’s TenHarmsel Farms cracked the code using repurposed grain bins with aeration systems. “We treat it like high-moisture corn,” says manager Kyle TenHarmsel. “Turn the fans on for 30 minutes twice daily—zero spoilage since 2023.”

Pro Tips from Industry Experts:

- Commodity Shed Essentials: Use walking floor systems and dump trucks for easier loading.

- Climate Adaptations: In humid regions, consider coated or pelleted WCS to prevent mold.

- Moisture Monitoring: Install automated sensors in bulk silos to track humidity levels.

Mixing Mastery: Preventing the Sorting Headache

WCS’s irregular shape makes it prone to sorting in TMR mixers. Here’s how top producers are tackling this:

- Pre-mix Strategy: Blend WCS with a small-grain component like ground corn before adding to the main mix.

- Vertical Mixer Magic: If you’re running a vertical mixer, add WCS last and limit mixing time to 3-5 minutes post-addition.

- Liquid Liaison: Some innovators are experimenting with adding molasses or whey permeate to “glue” WCS to other ration components.

The Gossypol Myth Busted

Anti-WCS lore claims gossypol risks trump benefits. Bloodwork from the 2025 trial tells a different story:

- Plasma gossypol levels: 4.2 μmol/L (WCS group) vs. 1.1 μmol/L (control)

- Toxic threshold: 25 μmol/L

Translation: You’d need to feed 35% WCS daily to hit danger zones. At 15%, it’s safer than your teenager’s TikTok habits.

Why This Matters

Gossypol’s bad rap stems from outdated studies on cottonseed meal (not whole seed). WCS’s slow fat release in the rumen minimizes absorption—a critical distinction lost on many nutritionists. Recent University of Georgia research confirms modern cottonseed varieties have lower gossypol levels and smaller seeds, further reducing risks.

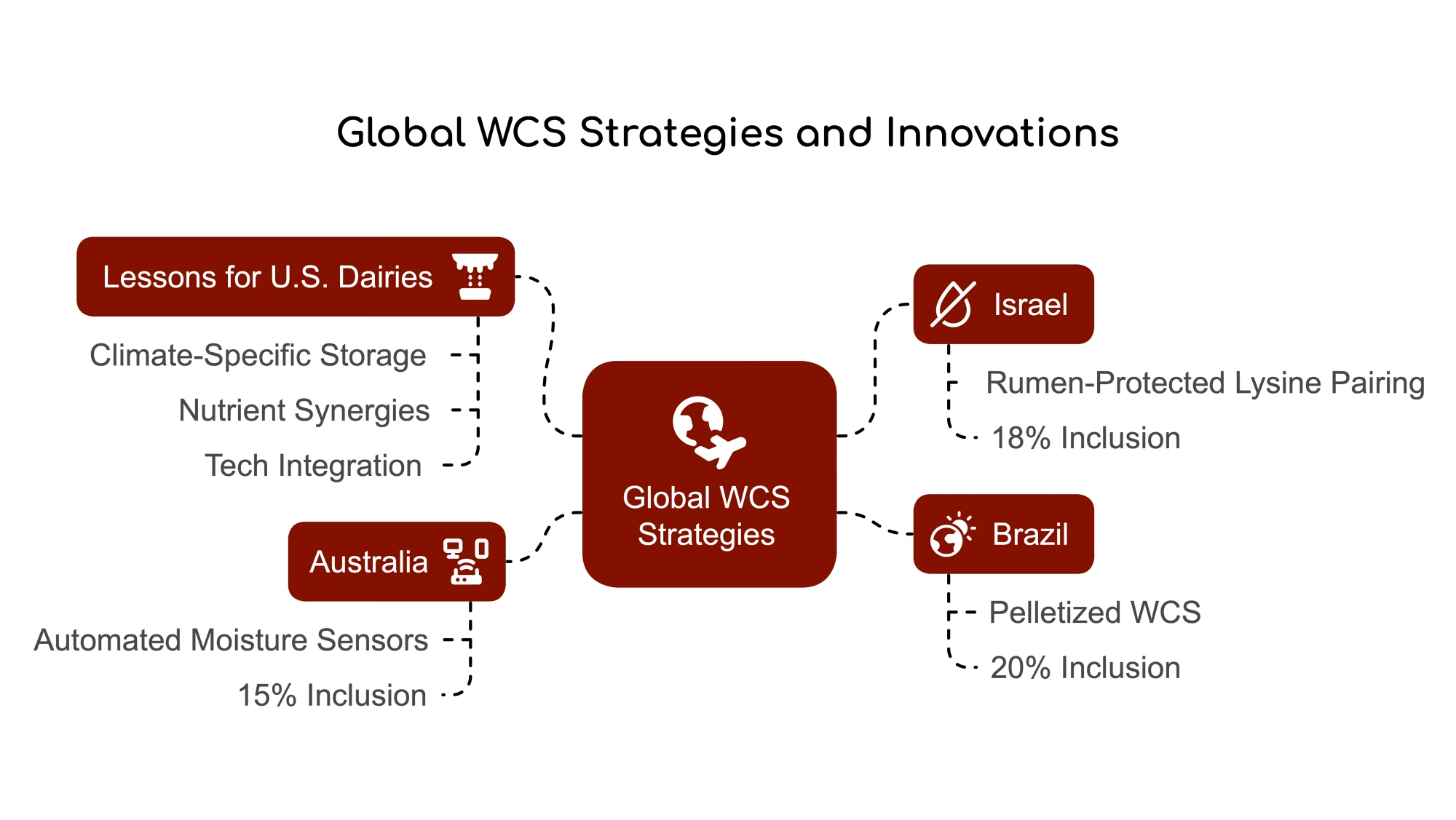

Global Playbook: What We Can Learn from International WCS Innovators

While U.S. farmers debate WCS, Israel’s top dairies run 18% inclusions year-round. “Our arid climate simplifies storage,” says Moshe Ben-David of Arava Dairy. “But the real secret? Pairing WCS with rumen-protected lysine. We’ve hit 4.1% milk fat consistently.”

Let’s break down global WCS strategies:

| Country | WCS Inclusion | Key Innovation |

| Israel | 18% | Rumen-protected lysine pairing |

| Brazil | 20% | Pelletized WCS for easier handling |

| Australia | 15% | Automated moisture sensors in storage |

Lessons for U.S. Dairies

- Climate-Specific Storage: Adapt Israeli dry-storage techniques for arid regions; use Brazilian pelletization in humid areas.

- Nutrient Synergies: Explore rumen-protected amino acid pairings to maximize WCS benefits.

- Tech Integration: Implement Australian moisture-monitoring systems for large-scale operations.

Environmental Considerations: The Methane Myth

Despite the hypothesis that WCS’s unsaturated fatty acids would reduce methane emissions, the 2025 trial found no significant effect. For farmers looking to reduce their carbon footprint, this feeding strategy may not provide the environmental benefits initially expected.

However, the lack of negative impacts on production, combined with improved feed efficiency, suggests WCS can be part of an economically and environmentally sustainable feeding program.

The Carbon Calculation

While WCS doesn’t directly cut methane, its efficiency gains indirectly reduce your farm’s carbon footprint:

- Less Feed, Same Milk: Higher feed efficiency means fewer resources used per cwt of milk produced.

- Transport Savings: Local WCS sourcing can slash your feed’s transportation emissions.

- Waste Reduction: Improved storage techniques minimize spoilage, cutting down on wasted resources.

Practical Implementation: Your 90-Day WCS Roadmap

Ready to jump on the WCS bandwagon? Here’s your action plan:

Week 1-2: Baseline and Sourcing

- Establish current milk component baselines

- Source WCS from reputable suppliers (aim for 16% fat, 21% protein)

- Set up storage infrastructure using commodity sheds or repurposed grain bins

Week 3-4: Introduction Phase

- Start at 5% WCS inclusion

- Monitor intake closely

- Conduct weekly milk tests

Week 5-8: Ramp-Up

- Gradually increase to 10% inclusion

- Adjust other ration components as needed

- Continue weekly milk tests

Week 9-12: Full Implementation

- Push to 15% inclusion if all metrics remain positive

- Fine-tune mixing protocol to prevent sorting

- Analyze IOFC changes

Post-Implementation

- Conduct a full economic analysis

- Adjust storage and handling based on farm-specific challenges

- Share results with your local dairy community

The Bottom Line: Is WCS Your Next Profit Driver?

Feeding whole cottonseed at 15% of the diet isn’t just safe—it’s a financial lifesaver in today’s $18/cwt milk market. But success demands:

- Precision Storage: No more dumping it in the back forty. Treat WCS like the premium ingredient it is.

- Component Tracking: If your co-op doesn’t pay for fat, this play isn’t for you (yet).

- Global Inspiration: Steal storage solutions from Israel, mixing strategies from Brazil.

Critical Considerations

- Processor Policies: Verify fat premiums before implementing.

- Bull Fertility: While the 2023 Auburn study showed no negative impacts on bull semen quality, WCS isn’t universally recommended for breeding programs.

- Regional Variability: Cotton residue grazing (common in Southern cow-calf operations) doesn’t translate directly to dairy systems.

Still skeptical? Run a 50-cow trial. Measure components weekly. Crunch the numbers yourself. Because in 2025’s dairy economy, the difference between red ink and black just might be sitting in a cotton gin’s byproduct pile.

Key Takeaways:

- Profit Boost: WCS at 15% increases milk fat yield by 10% and IOFC by $0.54/cow/day.

- Myth Busted: Gossypol risks are negligible at 15% inclusion, with plasma levels far below toxic thresholds.

- Global Strategies: Adopt storage innovations (e.g., aeration, pellets) and nutrient synergies from Israel/Brazil.

- Action Plan: Start at 5% inclusion, monitor components, and scale to 15% with proper mixing/storage.

- Critical Check: Confirm processor fat policies—premiums dictate WCS’s profitability.

Executive Summary:

Whole cottonseed (WCS) at 15% inclusion isn’t just safe—it’s a financial powerhouse. Recent University of Minnesota research shows WCS boosts milk fat yield by 10%, translating to $0.54/cow/day in income over feed costs. By replacing soybean meal and cottonseed hulls, WCS delivers fat, protein, and fiber in one ingredient, reducing storage and mixing hassles. Gossypol risks are minimal at 15% inclusion, with plasma levels well below toxicity thresholds. Global dairy leaders in Israel and Brazil leverage WCS through climate-specific storage (e.g., aeration systems, pellets) and nutrient pairings. However, farmers must verify if their processors reward fat premiums. Implementing WCS requires phased introduction, precise storage, and monitoring—but the payoff could transform thin margins into sustainable profits.

Learn more:

- Heads Up Dairy Farmers: Low Feed Prices Won’t Last

This article discusses the impact of cottonseed supply fluctuations on feed costs, offering insights into how regional harvests can affect pricing and availability for dairy farmers. - Maximizing Milk Solids Output Through Strategic Nutrition and Genetics

Focused on optimizing milk solids production, this article explores tailored feeding strategies, supplementation, and genetic selection to boost butterfat and protein yields. - 7 Steps to Enhancing Performance and Reducing Feed Costs in Dairy Cattle

This piece provides practical tips for incorporating alternative feeds like cottonseed into rations, balancing diets, and improving feed efficiency to lower costs while maintaining production.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Daily for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!