Bois Seigneur Holstein: Where tradition meets innovation in dairy farming. From humble beginnings to European champions, this Belgian farm has revolutionized breeding with the legendary Laurie Sheik lineage. Discover how the Pussemier family blends cutting-edge genetics with time-honored practices to shape the future of Holstein excellence.

Eddy and Annie Pussemier, pioneers of Bois Seigneur Holstein, stand alongside their son Jonas, who now leads the farm into a new era of innovation. This multi-generational team embodies the farm’s commitment to blending time-honored breeding practices with cutting-edge genetics, ensuring the legacy of excellence continues at Bois Seigneur.

Bois Seigneur Holstein has skillfully blended traditional and modern techniques. While incorporating tried-and-true methods, they have keenly observed changes in technology and consumer needs, swiftly adopting sustainable practices and advanced genetics. The success of Bois Seigneur Holstein has been significantly influenced by Comestar Laurie Sheik’s lineage, which has enhanced breeding programs and ensured high-quality offspring through meticulous herd management. Beginning humbly under the dedicated efforts of Eddy and Annie Pussemier, the farm’s reputation skyrocketed in the industry, showcasing the couple’s relentless hard work. Acquiring the renowned Laurie Sheik line has significantly enhanced their breeding programs for generations. Furthermore, their active involvement with the community in producing locally cherished cheeses and ice creams has bolstered their connections, cultivated a loyal customer base, and enriched community relationships. At Bois Seigneur, unwavering commitment and innovative approaches to adaptation, community engagement, and genetic advancements have paved the way for success, shaping a promising future in dairy farming.

A Legacy of Innovation: From Modest Beginnings to Genetic Excellence

Given his lack of a male heir to secure its future, Annie’s grandfather chose not to invest heavily in the farm, but Eddy and Annie were resolved to transform it into a thriving dairy farm. André Scolas, a seasoned dairy farmer, advised them to raise dairy cattle instead of beef cattle for a more reliable revenue source. This suggestion spurred their transition. The farm saw remarkable advancements due to Eddy’s mechanical acumen. However, it wasn’t until 1989 that the trajectory of their operations experienced a significant shift.

A historic moment at Comestar: The day they finalized the purchase of Comestar Laurie Sheik VG-88 in 1989. This pivotal decision would go on to shape the future of both Comestar and Bois Seigneur Holstein, revolutionizing Holstein breeding across Europe and beyond.

In 1989, Bois Seigneur Holstein took a big step. Eddy and Annie Pussemier wanted top cows from Canada for breeding but couldn’t due to strict rules about importing live animals. Marc Comtois from Comestar Holsteins suggested a brilliant idea: buy a cow and bring her embryos to Belgium. They chose a young cow named Comestar Laurie Sheik. They were impressed by her and decided to invest in her embryos. This decision changed everything for them. Laurie Sheik’s daughters became known for their strength and beauty, improving the farm’s performance and spreading to Europe. Today, 70% of their herd comes from Laurie Sheik, showing just how crucial that choice was.

Laurie Sheik changed everything, starting a successful breeding line that was essential to their breeding plans. The magic cross with Tomar Blackstar set off “Blackstar Mania,” with many daughters worldwide becoming instant bull mothers, including Blacklaure de Bois Seigneur and Belchief de Bois Seigneur for Bois Seigneur Holsteins. Blacklaure’s massive milk production of 100,000 kg and championship wins made her even more critical.

The strong genetics of the Laurie Sheik lineage affect 70% of today’s herd. This line always gives birth to top-notch, award-winning cattle, which helps Bois Seigneur’s famous milk production and elegance. Keeping this line in mind led to better breeding and a history of strength and excellence in the dairy industry.

Blending Tradition and Genomics for Dairy Excellence

Jonas and Astrid Pussemier: The dynamic duo steering Bois Seigneur Holstein into the future. Their shared passion for excellence in breeding and farm management ensures the continued success of this renowned Holstein enterprise. Together, they embody the perfect blend of tradition and innovation that has become the hallmark of Bois Seigneur Holstein.

When Jonas Pussemier returned to his family’s farm, it was a significant turning point in its history. After quitting his pharmaceutical manufacturing job, Jonas fully immersed himself in Holstein breeding, which his family had always done. He aimed to improve the farm’s reputation while maintaining quality and long-term viability. Jonas maintains dairy farming through strategic cow selection and attentive herd management, combining old-fashioned knowledge with modern genetic science.

Jonas Pussemier, the current steward of Bois Seigneur Holstein, stands proudly with his children Achille and Julia. This image captures the farm’s bright future, as the next generation learns the art of Holstein breeding, blending time-honored traditions with innovative practices. The Pussemier family’s commitment to excellence in dairy farming continues, ensuring Bois Seigneur’s legacy for years to come.

The Bois Seigneur Holstein farm stands out in the dairy world because it has excellent cattle and produces a lot of milk. The owners prioritize both their cows’ aesthetic appeal and performance efficiency. They meticulously choose optimal genetic traits, utilize modern tools such as genomic sires, and closely monitor key cow characteristics to achieve an ideal genetic mix.

Recent breeding decisions often rely on genomic testing. Although the genomic sires have impressive numbers, Bois Seigneur values good mothering more than high production. With genomic bulls, they focus on traits and bloodlines that have been shown to work, not just one bull. To improve their herd, they want to spread out the genetic choices instead of relying on a few sires.

Chief and Lambda are the plan’s top sires. They help the farm reach its goals of having cows that do well in milk production and show competition. Bois Seigneur makes a herd that stands out in the barn and at shows by choosing sires with great looks. They aim to get lots of milk from cows and keep them working for a long time. They want to show that good looks and performance work together to get lots of milk.

The farm is successful because it cares about how its cattle look and perform. By focusing on both, Bois Seigneur Holstein raises cattle that do well in shows and are the best in quality and milk production.

The Strategic Role of Show Participation in Enhancing Bois Seigneur Holstein’s Breeding Success

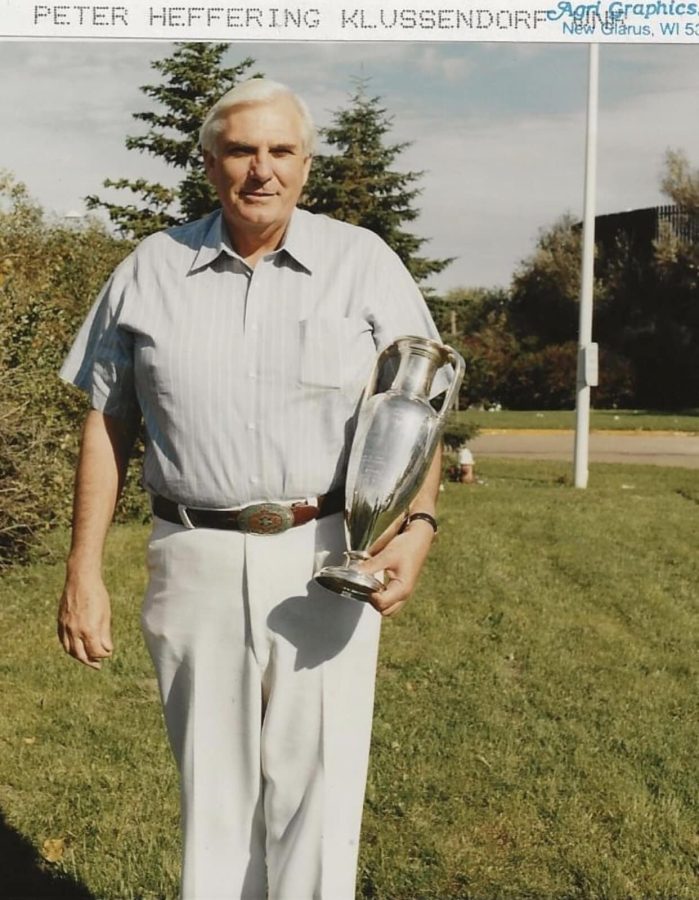

Its success at many prestigious dairy shows—often finishing in the top five at the European Championships—shows its commitment to being the best. These events help it decide what to breed and support its marketing. Competing at these kinds of shows brings more attention to the farm. It gives the Pussemier family a chance to showcase their well-bred cows and meet potential customers from all over Europe. The company’s breeding strategy is based on producing beautiful, high-performing cows that meet show standards while improving the herd’s quality and genetics.

Maxima de Bois Seigneur (Chief) EX 94: A powerhouse of production, pictured after setting a new farm record of 80 kg milk in 24 hours at just 47 days in milk. Rosalina de Bois Seigneur (Chief) EX92 – 94 MS: Showcasing the breed-defining type that has made Bois Seigneur Holstein a leader in European show rings. These two Chief daughters exemplify Bois Seigneur Holstein’s commitment to blending exceptional production with show-winning conformation.

Cows like Maxima de Bois Seigneur show their accomplishments now classified EX 94, whose performance in competitions shows how well Bois Seigneur’s breeding methods work. These prize-winning cows bring attention to the farm in the dairy community and help it build a reputation for high-quality animals. Bois Seigneur Holstein uses show wins as a marketing tool to show the value and potential of their genetics in both domestic and international markets. This helps them keep their position as leaders in dairy breeding and production.

Maxima de Bois Seigneur (Chief) EX-94 in her prime: Pictured here in her third lactation, this exceptional daughter of Chief exemplifies Bois Seigneur Holstein’s breeding philosophy. With her combination of show-ring style and impressive production, Maxima demonstrates the farm’s success in creating cows that excel in both type and performance, setting new standards for the Holstein breed.

Innovative Infrastructure: Harmonizing Tradition with Technological Advancements at Bois Seigneur Holstein

Bringing Bois Seigneur Holstein’s facilities up to date is an essential step toward more caring dairy production. They use new ways to ensure the cows are comfortable and happy while honoring old ways. The free-stall barn, which has large stalls, lots of natural light, and views of the pastures, is at the heart of these improvements. Cattle rest on soft, deep straw beds that keep their feet safe. Different-sized cows can fit through flexible walls that keep them from rubbing against each other and getting hurt, and maintaining happy cows increases their milk production and life span.

The barn’s open layout makes it easy to monitor the whole area so that any problems can be found and fixed quickly. The climate is controlled by automatic curtains that let in fresh air and keep the environment in sync with the cows’ natural rhythms. This balance suits their health, makes them more comfortable, and helps them get more done.

The state-of-the-art free-stall barn at Bois Seigneur Holstein, completed in 2017, showcases the farm’s commitment to cow comfort and modern dairy practices. With its open design, natural lighting, and advanced ventilation system featuring Goderis Cowcompany’s basket fans, this facility embodies the Pussemier family’s dedication to blending tradition with innovation for optimal herd health and productivity.

The way they work has changed since automated milking systems were installed. Since robotic milking machines were installed, cows have produced an average of 11,000 kilograms of high-quality milk annually. Data-based decisions help create methods that are kind to each animal and the community. These improvements show that Bois Seigneur Holstein cares about the environment. They use modern and traditional techniques to improve their beloved dairy cows’ lives, welfare, and productivity.

Innovative Diversification: Strengthening Consumer Connections and Financial Stability at Bois Seigneur Holsteins

To grow its business, Bois Seigneur Holstein has added a milk vending machine and started making cheese and ice cream. This smart move has helped the company get to know its customers better. The vending machine at Bois Seigneur Holstein sells locally produced dairy products like cheese, ice cream, and fresh milk at any time. This meets the demand for high-quality local goods and builds a loyal customer base of people who like buying directly from the farm.

Because of this expansion, the farm is now financially safer. The farm aims to maintain a small herd while ensuring economic stability, with additional revenue from these products supporting this goal. Their story shows how small family farms can remain competitive in today’s market by leveraging their strengths, such as location and selling directly to customers.

But as the farm grows, some problems arise. One is that it’s hard to find skilled people to take over jobs when important people retire, like Annie Pussemier, who is responsible for making dairy products. Another is getting more help without losing money on the farm.

Adding cheese, ice cream, and a vending machine has helped the farm build customer relationships and earn more money. Still, careful planning will be needed for future success. In a constantly changing agricultural and economic world, the farm must maintain its unique product quality and personal touch while using environmentally friendly methods.

Jonas Pussemier stands proudly beside Maximisee de Bois Seigneur (Maximus), the exceptional dam of the renowned Maxima de Bois Seigneur. This image showcases the farm’s commitment to breeding excellence, with Maximisee exemplifying the high-quality genetics that have made Bois Seigneur Holstein a leader in both show rings and production. Her daughter Maxima’s recent achievements, including over 60,000 kg of milk in her fourth lactation, demonstrate the lasting impact of the farm’s breeding program.

Preserving Excellence: The Pussemier Family’s Commitment to Sustainable Dairy Success

The Pussemier family wants to keep Laurie Sheik’s memory alive by maintaining a top dairy herd. They want to improve the herd in the next ten years without changing their core beliefs. This means hard work on the herd’s genetics, which is both challenging and satisfying. To keep Bois Seigneur Holstein at the top of breeding standards, they are considering adding new bloodlines from the best families worldwide.

They prioritize quality and sustainability. The Pussemiers get to know each animal well by keeping their business small. This personalized approach produces high-quality milk and aligns with their goal of farming in an environmentally friendly way. Their updated facilities show they balance old-fashioned ways of doing things with new, cutting-edge ideas.

But in Europe, Holstein breeders now have to deal with strict health rules and changing business conditions, which can be hard to plan for. As global markets and consumer tastes change, adjustments must always be made. Strict EU rules that protect public health and animal welfare can make it hard to bring in new animals or grow herds.

Despite these problems, the Pussemiers are still hopeful and sure of themselves. Their outstanding achievements at prestigious dairy shows, consistently finishing in the top five at the European Championships, and innovative creations like unique dairy products showcase their passion and dedication to their work. Their work shows you can be the best if you work hard and plan. Looking ahead, their goal is to achieve long-term success responsibly and sustainably, ensuring that Bois Seigneur Holstein’s legacy endures for future generations, reflecting their dedication to preserving excellence in dairy farming.

The Bottom Line

Bois Seigneur Holstein stands as a remarkable testament to harmonizing time-honored techniques with modern innovations in dairy farming. The Pussemier family remains dedicated to nurturing the descendants of the legendary Laurie Sheik by skillfully balancing high milk production with robust maternal lines. They epitomize leadership in their industry by integrating advanced technologies such as genetic testing and robotic milking while simultaneously upholding traditional breeding practices and embracing diversification.

Key Takeaways:

- The Pussemier family’s forward-thinking approach transformed their farm into a significant player in Holstein breeding through strategic investments and innovation.

- Bois Seigneur Holstein combines traditional breeding values with modern genomics to achieve exceptional herd performance and show success.

- Show participation is integral to BSH’s strategy, enhancing visibility and credibility in the competitive dairy industry.

- The construction of a state-of-the-art free-stall barn and the adoption of robotic milking have significantly improved cow comfort and productivity.

- Diversification into dairy products like cheese and ice cream and direct consumer engagement strengthens economic stability.

- The Pussemier family is committed to sustaining excellence and fostering sustainable practices in the dairy sector to maintain their position as industry leaders.

- The farm’s success hinges on continuous improvement, dedication to quality, and adapting to industry advancements.

Summary:

Bois Seigneur Holstein in Belgium is a standout dairy farm that mixes old-school farming with new-age technology. Led by the Pussemier family, the farm has grown from its small start to become a leader in the dairy world, focusing mainly on cows from the Laurie Sheik family. These cows are beautiful and great milk producers, frequently winning show awards. The farm uses traditional breeding methods and modern genomic tools to keep this high quality. They also make and sell dairy products like cheese and ice cream to connect directly with customers. With new facilities, they ensure cow comfort and high productivity, aiming for long-term success by possibly bringing in top family bloodlines from around the globe.

Learn more:

- Expo Bulle 2024: The Swiss National Holstein Show That Set New Standards

- New Leadership & Trustee Elections at Holstein UK Annual General Meeting

- The Dark Side of Dairy Business: Seven Notorious Criminals in the Dairy Industry Unveiled

Join the Revolution!

Join the Revolution!

Bullvine Daily is your essential e-zine for staying ahead in the dairy industry. With over 30,000 subscribers, we bring you the week’s top news, helping you manage tasks efficiently. Stay informed about milk production, tech adoption, and more, so you can concentrate on your dairy operations.

Join the Revolution!

Join the Revolution!