Discover how 200+ ft/min airflow boosts milk yields, cuts $1.5B heat losses, and keeps cows lying comfortably through summer’s worst heat waves.

EXECUTIVE SUMMARY: Heat stress costs U.S. dairies $1.5B annually through reduced milk yields, reproductive failures, and health issues. Groundbreaking research reveals that maintaining consistent 200+ ft/min airflow at cow level – not just average barn ventilation – prevents production drops by enabling natural lying behavior. Advanced systems like AirBreeze combine precision cooling with energy efficiency, while strategic fan placement eliminates “hot spot” competition between cows. Producers implementing these airflow standards report maintained feed intake and conception rates even in extreme heat, with ROI achieved in 1-2 seasons through prevented losses. Emerging AI-driven systems and heat-tolerant genetics promise next-level resilience as temperatures rise.

KEY TAKEAWAYS:

- Non-negotiable airflow: 200+ ft/min at resting height prevents 5-15 lb milk loss/cow/day

- Consistency trumps averages: ≤10% stall-to-stall airflow variation maximizes lying time

- Profit protector: Every $1 in cooling upgrades saves $3-5 in heat-related losses annually

- Action steps: Anemometer testing → fan recalibration → combine with timed soakers

- Future frontier: AI cooling systems now adjust airflow per cow’s real-time thermal needs

As we approach the summer of 2025, dairy producers face an increasingly critical challenge: protecting their herds from the devastating effects of heat stress. With global temperatures rising and the U.S. dairy industry losing up to $1.5 billion annually to heat-related issues, the need for effective cooling strategies has never been more urgent. Recent groundbreaking research has revealed that the key to maintaining cow comfort and productivity lies in providing cooler air and ensuring consistent, high-speed airflow throughout the barn. This article delves into the latest findings and cutting-edge technologies transforming how we approach heat abatement in dairy operations.

THE HIDDEN COSTS OF HEAT STRESS

When temperatures climb, the impacts on your herd are immediate and measurable. Heat-stressed cows display a cascade of behavioral and physiological changes directly impacting your operation’s productivity. Most producers have witnessed firsthand how rising barn temperatures cause cows to dramatically reduce feed intake, resulting in significant drops in milk production – often 5-15 pounds less milk per cow daily during heat events.

Beyond production losses, heat stress triggers behavioral changes that signal distress. Observant farmers notice cows spending less time at the feed bunk and more time clustered around water troughs and exhibiting concerning increases in standing time versus lying down to rest. This standing behavior persists even on operations with feedback soakers installed, indicating that partial cooling solutions aren’t enough for comprehensive heat abatement.

The reduction in lying time is particularly concerning, as inadequate rest compromises cow health, longevity, and productivity. Research shows that cows naturally require 12-14 hours of lying time daily to maintain optimal health and production. Heat stress forces them to choose between thermal comfort and adequate rest, creating a no-win situation that manifests in higher respiration rates, elevated body temperatures, and compromised immune function.

These effects aren’t just temporary setbacks. Research shows that the negative impacts of heat stress can linger for weeks after temperatures cool, creating long-lasting production setbacks. Heat events during critical reproductive windows can depress conception rates for months afterward. In contrast, the metabolic challenges of heat stress can trigger health issues ranging from ruminal acidosis to lameness, further eroding profitability long after temperatures moderate.

THE SCIENCE OF STRATEGIC COOLING

Recent studies have uncovered a critical factor in effective heat abatement: consistent, high-speed airflow. Controlled experiments at the University of Wisconsin-Madison research dairy farm have demonstrated that fans calibrated to deliver air speeds of at least 200 feet per minute (1 meter per second) at cow resting height produce remarkable results across multiple parameters. Cows maintained regular respiration rates and body temperatures – key physiological indicators showing reduced heat stress – while maintaining dry matter intake levels and milk production even as temperatures climbed.

Perhaps most significantly, these properly ventilated cows continued standard lying behavior patterns during hot weather – a critical discovery given how heat typically drives cows to spend more time standing. This finding represents a significant breakthrough in our understanding of heat abatement, as it addresses the production impacts of heat stress and the welfare concerns associated with reduced rest.

The cooling effect of moving air works through several mechanisms simultaneously. High-speed airflow increases convective heat loss from the cow’s body surface, pulling heat away faster than still air could. This convective cooling becomes even more powerful when combined with evaporative cooling systems like soakers, where the moving air accelerates water evaporation from the cow’s hide, creating a powerful cooling effect that can reduce body temperature significantly more than either method alone.

Research indicates that strategic fan placement creates microclimates within barns where cows can access relief even when ambient conditions remain challenging. Studies at multiple universities have documented that cows actively seek these cool zones, confirming the intuitive observation that cows deliberately position themselves under the streaming air from fans. This behavioral preference provides strong evidence that cows recognize and value the cooling effect of high-speed air.

REVOLUTIONIZING BARN DESIGN: THE AIRBREEZE ADVANTAGE

Cutting-edge ventilation systems like the Multifan AirBreeze are at the forefront of this cooling revolution. These advanced systems deliver consistent airflow of 2 m/s (394 feet per minute) at cow level – well above the minimum threshold established by research. Unlike traditional ventilation approaches that often create variable conditions throughout the barn, these systems are designed to maintain uniform airflow across all resting areas.

The technology incorporates intelligent control based on temperature and humidity, automatically adjusting fan speed to maintain optimal conditions as environmental factors change throughout the day. This responsive approach ensures cows receive appropriate cooling when needed most while conserving energy during cooler periods. The energy-efficient operation with variable speed technology represents a significant advancement over older all-or-nothing fan systems, reducing electricity costs while improving cooling effectiveness.

Another key focus of these advanced systems has been durability in harsh barn environments. Manufacturers have addressed the challenges of dust, moisture, and ammonia exposure that typically shorten the lifespan of ventilation equipment in agricultural settings. The result is cooling infrastructure that maintains performance season after season with minimal maintenance requirements.

By maintaining optimal airflow, these systems help reduce heat stress markers like elevated respiration rates and body temperatures. They encourage consistent feed intake patterns even during heat events, supporting milk production when traditional cooling approaches often fall short. The comprehensive approach to barn climate management represents a significant step in protecting dairy productivity during increasingly challenging summer conditions.

IMPLEMENTING EFFECTIVE COOLING STRATEGIES

To maximize the benefits of high-speed air cooling, dairy producers should take a systematic approach to evaluating and optimizing their ventilation systems. The priority is measuring actual air speeds at cow resting height – approximately 20 inches above each stall surface. This critical measurement provides the ground truth about what your cows are experiencing, not what your system was theoretically designed to deliver. Portable anemometers simplify this assessment, allowing you to map airflow patterns throughout your facility.

Focus on identifying stalls with suboptimal airflow (below 200 feet per minute) and areas with significant variation between adjacent stalls. These trouble spots become your priority for system adjustments and modifications. Often, simple changes to fan positioning or angles can dramatically improve airflow distribution, eliminating dead zones and creating more uniform conditions throughout the barn.

In some cases, supplemental fans may be needed to address structural challenges that create ventilation shadows. The goal is to ensure uniform airflow across all stalls to prevent competition for cooler areas. When airflow varies significantly between stalls, it creates a hierarchy of desirability—cows naturally prefer stalls with better cooling, leading to potential competition and social stress. Dominant cows may monopolize the best-ventilated areas, forcing subordinate animals to choose between thermal discomfort or inadequate rest.

Consider combining high-speed air with other cooling methods like soakers for maximum cooling effect. This integrated approach leverages the synergistic relationship between evaporative and convective cooling. The soakers wet the cow’s coat while the high-speed air accelerates evaporation, creating a powerful cooling effect that independently exceeds what either method could achieve. This combination has proven particularly effective in holding areas, where cows are especially vulnerable to heat stress due to crowding.

THE ECONOMIC CASE FOR IMPROVED COOLING

Investing in optimized cooling systems delivers returns through multiple pathways, creating a compelling economic case for action. The most immediate and visible benefit is maintained milk production during hot weather. Consider that a typical heat-stressed cow may produce 5-15 pounds less milk daily during hot weather. For a 500-cow dairy, this translates to 2,500-7,500 pounds of lost milk production everyday, temperatures exceed the cow’s comfort threshold. At current milk prices, these losses quickly justify investments in comprehensive cooling solutions.

The whole economic picture extends beyond immediate milk production. Heat stress compromises reproductive performance, with studies showing significant reductions in conception rates during and following heat events. Each extension of days open represents additional costs in delayed lactations and potential culling decisions. Research indicates that heat stress during breeding can reduce conception rates by 20-30%, creating a cascade of reproductive inefficiencies that impact profitability for months afterward.

Heat-stressed cows face increased health challenges, from lameness (exacerbated by extended standing times) to ruminal acidosis (resulting from altered feeding patterns). These secondary effects create veterinary costs, treatment expenses, and potential premature culling – all avoidable with effective cooling strategies focused on consistent airflow. The enhanced longevity of animals in well-cooled environments represents a significant economic advantage, allowing producers to maximize lifetime production from their genetic investments.

Producers should consider this comprehensive picture of benefits when calculating return on investment for cooling system improvements. The initial capital expenditure for upgraded ventilation often pays for itself within 1-2 seasons through prevented production losses alone. The economic case becomes even more compelling when the additional benefits of improved reproduction, reduced health issues, and extended cow longevity are factored in.

LOOKING AHEAD: THE FUTURE OF DAIRY COOLING

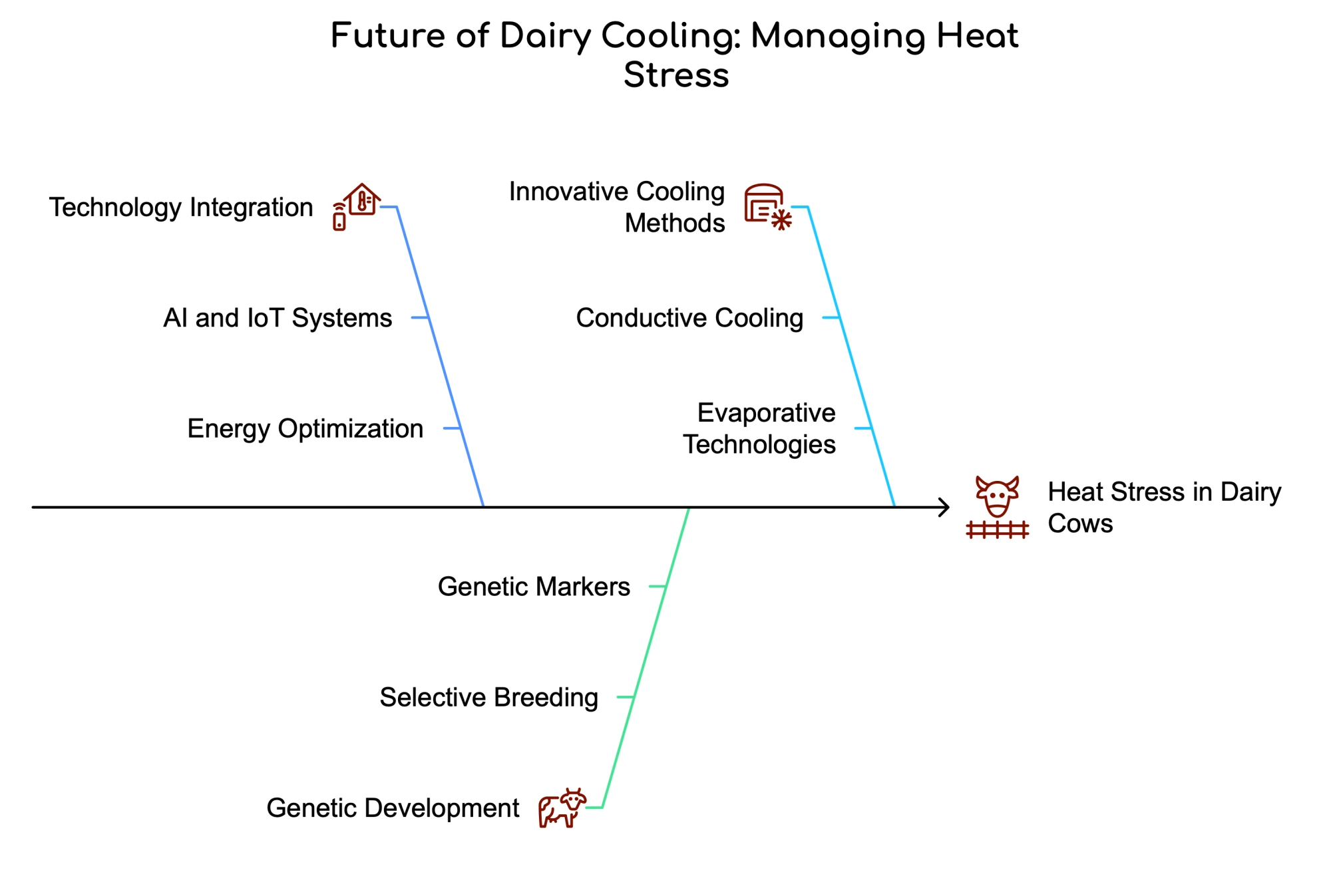

As we continue to face rising global temperatures, the importance of effective heat abatement will only grow. Climate projections suggest that the frequency and intensity of heat events will increase in traditional dairy regions, making heat stress management an essential component of sustainable production. Forward-thinking producers are already exploring emerging technologies that promise to take cooling effectiveness to new levels.

Integrating artificial intelligence and Internet of Things (IoT) technology creates new possibilities for precision cooling management. Advanced systems can now monitor individual cow behavior, physiological parameters, and environmental conditions in real time, automatically adjusting cooling systems to maintain optimal conditions. These smart-systems optimize energy use while maximizing cooling effectiveness, representing the next frontier in heat abatement technology.

Developing heat-tolerant genetics through selective breeding offers another promising long-term heat stress management avenue. Researchers have identified genetic markers associated with superior heat tolerance, opening the possibility of selecting this trait alongside traditional production characteristics. While genetic approaches won’t eliminate the need for effective cooling systems, they may provide an additional layer of resilience against heat challenges.

Exploration of novel cooling methods beyond traditional fan and soaker systems continues to yield promising innovations. Researchers and equipment manufacturers are constantly pushing the boundaries of what’s possible in dairy cooling, from conductive cooling through specialized flooring materials to advanced evaporative cooling technologies. These emerging approaches may soon complement or even replace current methods, further enhancing our ability to protect cows from heat stress.

THE BOTTOM LINE

The latest research confirms what progressive dairy producers have observed – proper airflow is essential for summer cow comfort, but consistency matters as much as intensity. Ensuring all stalls receive air speeds of at least 200 feet per minute creates an environment where cows can maintain normal behaviors, even during heat challenges. This consistent approach addresses heat stress’s production and welfare aspects, protecting your bottom line and supporting animal wellbeing.

The approach is straightforward: measure, identify variations, make targeted adjustments, and maintain your equipment. This systematic strategy transforms summer cooling from a reactive effort to a proactive system that maintains cow comfort, protects productivity, and enhances welfare during challenging weather. As temperatures rise, your investment in strategic cooling could be the difference between struggling through summer and maintaining peak performance year-round.

By focusing on consistent, high-speed airflow, dairy producers can transform their approach to heat abatement from a reactive effort to a proactive system that maintains cow comfort, protects productivity, and enhances welfare during increasingly challenging summer conditions. Your cows are “fans” of high-speed air – and your bottom line will be, too.

Learn more:

- Understanding How Leaky Gut Exacerbates Heat Stress in Dairy Cows

Explores the hidden link between intestinal health and heat stress impacts, detailing how metabolic disruptions cost producers 20-50% of milk losses. - Long-Term Impact of Heat Stress on Dairy Cattle

Reveals heat stress’s $1.5B/year multigenerational toll, including fetal development risks and immune system erosion that threatens farm sustainability. - Modern Dairy Cows Suffer More Heat Stress

Analyzes how high-production genetics increased thermal vulnerability and presents mitigation strategies through barn tech, selective breeding, and targeted nutrition.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Daily for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!