There is no question that Robotic Milking Machines seem to be the hottest thing on the market. With over 35,000 robotic milking systems (RMS) operational on dairy farms around the world, it more than just a fad, it is an epidemic. It seems almost daily you hear about another operation deciding to switch to Robots. With many producers citing the improved lifestyle and the ability to expand or even stay in business without having to hire more labor. And it’s not just the old dairy farmers with kids who don’t want to work hard, more and more it seems like even large dairies are considering the change. But the Bullvine asks “At what cost?”. Are these farmers generating greater income and because of better results on the bottom line that they can justify the expense? With that in mind, we decided to look at the economics of investing in robotic milking and determine if these farmers are lazy or are they smart business people.

Labor is the second largest expense on the dairy farm. Considering the actual cost of hired labor and when an appropriate value for unpaid family help is included, investing in labor-saving automation may be the best way to improve your bottom line.

Are you cheap or wise?

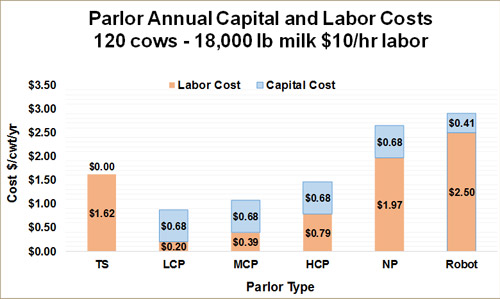

First, let’s get one thing clear, most producers do not install robots because it is the lowest cost option for harvesting milk. Historically, for a 120-cow dairy, the total cost per cwt of milk of a robotic milking system was similar to a new modern parlor.

Tie stall (TS) – $35,400 labor/yr

Low cost parlor (LCP) – $25,000 capital ($4,250 annual), $14,600 labor

Medium cost parlor (MCP) – $50,000 capital ($8,500 annual), $14,600 labor

High cost parlor (HCP) – $100,000 capital ($17,000 annual), $14,600 labor

New parlor (NP) – $250,000 capital ($42,500 annual), $14,600 labor

Robot – (10% increase in milk) $59,600 annual

(Source: http://www.extension.umn.edu/agriculture/dairy/precision-dairy/milking-robots-do-they-pay/)

But how many decisions on the average dairy farm are made to be at the lowest cost? Most of us decide not to live in the cheapest house or drive the cheapest car because we want a nicer lifestyle. But at the rate at which labor expenses are increasing, especially when the appropriate value for unpaid family help is included, not to mention the scarcity of labor, combined with the increased performance that is tied to the improved management, more and more Robots are beginning to make economic sense.

While coming up with hard numbers, which are applicable are specific to each situation, is almost impossible, one thing is clear is that robotic milking becomes more affordable every year as the cost of labor increases and the availability of labor decreases. There is no question that robotic milking saves labor, and based on surveys done by the Progressive Dairy Operators group (PDO), dairy farm labor is going up in cost. In 2004 the average wage for dairy farm workers described as “milkers” was $12.65 per hour. By 2004 this had gone up 7% to $13.55. Then in 2010 117 herds reported an average wage of $14.21 per hour for milkers, up 5% again plus an additional $0.28 in non-monetary benefits. So in 6 years, the benefit of owning a robotic milking system has increased by roughly 12%. (Read more: Robotic milking gets more affordable every year by Jack Rodenberg)

So how do you determine the ROI of an RMS?

To determine the real return of investing in a Robotic Milking System, you need to look at milk production per cow, milk produced per robot per day, labor savings, the length of useful life of the system.

The main cost of robotic milking is the capital invested in the technology. From 2004-2010 the price for a new robot went from $250,000 to about $220,000. That is a 15% decrease in the cost while labor costs have typical gone up 12%. That is a 27% swing in a six-year period. And in the last six years, prices for a robot to milk 50-70 cows is about $150,000 to $200,000, another 20 decrease. In that same time, the cost of wages paid to livestock workers per USDA has increased 19%. Researchers have reported up to 29% savings with RMS.

Another aspect that may be even more important, than the increased cost of labor for dairy farm workers, is the decreased availability. A 2014 survey indicated that 51% of all farm labor was immigrant labor (Adcock et al., 2015). The future availability of immigrant workers may be reduced if less foreign workers choose to work on farms or if tighter immigration laws are passed in the US as the Trump administration seems to be leaning towards. And if Trump is successful at re-igniting the US economy revs up with reductions in regulations or the anticipation of that, the demand for labor is only going to increase in all industry, causes an even greater shortage of farm laborers. This will force producers to either use new workers who are very inexperienced yet demand a high wage or use an aging workforce that is not as productive as it once was. This already causing producers of all sizes to determine if they should either automate milking and eliminate task oriented positions, or increase productivity efficiencies to 180-200 cows per man with such technologies as teat spray robots in large rotaries.

So does an RMS make economic sense for your operation?

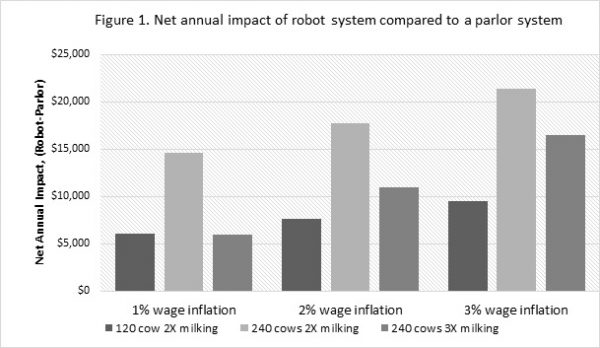

To answer this question, the University of Minnesota developed a web application to compare the profitability of robots and parlors: http://z.umn.edu/RobotParlor. This tool was used to compare the economics of RMS and parlor systems on farms with 120, 240 and 1,500 lactating cows over a 20-year payback time. Milking labor costs were set at $16/hr with a milk price of $17/cwt. They assumed milk production would increase 5 lb/day per cow with RMS compared to milking 2X and decrease 2 lb/day compared to 3X milking. The per cow barn investment is higher for the RMS, reflecting the additional cost to install labor savings features typical in RMS barns. We inflated labor costs at 1, 2, or 3% annually. Net annual impact refers to the net present value of projected differences in RMS cash flows converted to an annuity.

The 120 and 240 cow RMS systems had a higher net annual impact compared to a double 8-parlor system (Figure 1). Labor cost inflation and milk production per cow had a large impact on profit. For each pound change in daily production per cow, the net annual impact changed by $931.

The 1,500-cow parlor system was more profitable than RMS. A 1% annual wage inflation resulted in a $162,672 (3X milking) and $51,177 (2X milking) more profit for the parlor. The difference was $130,570 (3X milking) and $32,395 (2X milking) at 3% wage inflation. Using similar milk production and 3% wage inflation the parlor had $80,672 higher annual impact.

The primary reason for the differences in profit is the more intensive use of the milking system. The RMS assumed full utilization at 60 cows per robot across all herd sizes. The parlor was only being used four hours per day with the 120-cow system. In the 240-cow simulations, the parlor was being used 8 and 12 hr/day in the 2X and 3X respectively. For the 1,500-cow herd, both the robot and parlor were at near maximum utilization.

Milk production and labor assumptions between the systems significantly affect the profitability projections. More research is needed to understand the economics of how these systems perform with different herd sizes and management practices.

The University of Minnesota also determines just what are the breakeven rates for the Robotic system.

- Breakeven labor rate.

Since the 1,500-cow RMS was less profitable than the parlor system at $16/hr labor, they determined the breakeven labor rate at which the two systems would have similar annual incomes. At the wage inflation rate of 1% and a 2 lbs. lower milk production with the RMS, the breakeven labor rate is $32.30/hr. If similar milk production levels are assumed with a 3% annual wage inflation, the breakeven wage rate drops to $22.91/hr. - Breakeven milk production

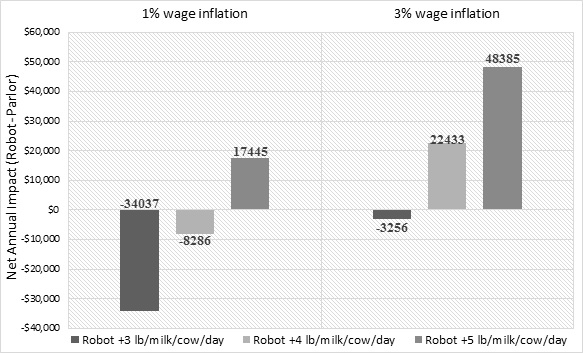

The University of Minnesota also examined how increased milk production per cow in RMS would affect the profit comparison (Figure 2). If the robot system achieves 3 lbs /cow per day higher milk production than the parlor with 3% annual wage inflation, the annual income is only $3256 higher for the parlor for the 1,500 cow herd. At 5 lbs./day more milk, the RMS is more profitable at all wage inflation rates. Current research indicates that RMS do not achieve milk production as high as 3X milking, but as RMS management and facility design improve, this may change. Another potential advantage is that cows in RMS can be managed and milked in stable groups within the pens. Cows have access to resources (feed, water, beds, and milking) at all times. More precise feeding management can potentially increase milk per cow.

Figure 2. Net annual impact of a 1,500-cow dairy with 25 robots compared to a double-24 parlor milking 3X at different increases in daily milk production and wage inflation rates

Maximizing the Robotic Impact

Maximizing daily milk per robot is important to maximize profit. In a four-robot system using 2% annual wage inflation and a 20-year time horizon, net annual income increases approximately $4,100 for every 500 lbs. increase in daily milk per robot. Currently, some US farms are consistently harvesting more than 6,000 lbs. of milk per robot daily. This is achieved by a combination of high daily milk per cow and a high number of cows per robot (often over 60). The most important factors to achieve this are:

- Milking permission settings and strategies that get the correct cows milked at the correct times

- Reduced box time per cow

- RMS in top working condition

Retrofit vs. New Barn

One question many producers must consider is it better to retrofit your current barn or build a new one? The University of Minnesota also examined how the economic life, labor efficiency, and milk production change affects the profitability of RMS. They developed two scenarios using an 180-cow dairy: RMS replacing a parlor and retrofitted in an existing freestall barn and an RMS in combination with a new high technology freestall barn. Here is what they found:

- Robot retrofit

For the retrofit scenario, they assumed that there was no remaining debt with the previous The increases in costs with the robots were payments for the three robots ($63,000) for ten years, higher insurance ($2,700) and higher maintenance ($9,000/robot per year). They examined profitability using milking labor of 45, 60 and 75 minutes per robot. They also varied daily milk per cow using a 2 lb decrease, no change, and 2 lb increase compared to the previous system. Their survey of producers indicated that well designed (automatic manure removal and split entry pens), well managed free flow barns average about 45 minutes of daily milking like labor per robot. In this scenario, if producers can get 2 lb/day more milk and robots last longer than ten years, the RMS system is more profitable than the parlor system. If there is no change in milk production, robots must last 13 (with 45 minutes of daily labor per robot) to 17 (with 75 minutes of daily labor per robot) years to break even. If milk production decreases 2 lb in the RMS system, it is never as profitable as the previous parlor system. - Robot with a New Barn

To achieve the maximum benefit of robots, it is preferable to design them into a new, high technology, low labor requirement facility. This includes various upgrades, such as wider more frequent crossovers, automated manure removal, and automated feed pushers. The projected new facility resulted in annual payments of about $101,000 over 20 years for the 180-cow farm. A 10 lb/ day increase in milk production along with the anticipated labor savings is required before robots are consistently more profitable than the previous parlor system. A key factor is the benefit of a Cow Comfort Upgrade and its effect on performance with robotics. When cow comfort is done right (sand is the gold standard) 60% of the milk increase in robotics can be attributed to the updated free stall barn. These things matter. The key benefit of individual robots is the elimination of the holding pen and the extra hours per day that the cow gets to eat, lay down, and chew her cud.

There are Economic tools available to do the deep dive and evaluate the many factors that affect performance and economics in a robotic milking facility. Contact your Robotic Specialist to sit down and go over the numbers and conditions specific to your dairy. Also, talk to your local dealer, banker, nutritionist, veterinarian, and genetics supplier. It takes a team working together to cover all the bases and give you the honest feedback to understand your operations strengths and weakness. 0ver 40,000 robots milk over 2.2 million cows worldwide and robots put in 16 years ago, are still operating today. It may be new to you, but it is not new to the industry. My Grandfather milked cows by hand, and 90 years later we are milking cows with no hands….amazing progress with more to come.

The Bullvine Bottom Line

While many producers look at income over feed to determine how their operation is doing. I argue that given the fact that labor is your actual greatest non-feed expense on a dairy farm, and that it is also the resource that is typically in the shortest supply, we should be looking at income per full-time labor unit. When you look at your operation, and if there is the capital required to invest in an RMS unit, there is not question that Robotic Milking Systems make perfect sense for most dairy operations under 1,000 milking cows. There is no doubt there will always be demand for high-quality people both immigrant and citizens. WE NEED COW PEOPLE!! Good people will always have a place in this industry, and they will have great value. The best robot barn in the world with poor management is a failure in the making. As someone recently said “Management Makes Milk” and “Good People make Managers Look Good.” There are more career opportunities in dairy than ever before, and those that can operate robotic facilities and use technology will have a very bright future. Especially with rising labor rates and less supply, there are also scenarios where a robotic milking system makes sense even for larger operations. Treat your cows with care, treat your employees with respect and develop them and the results can be predictable and positive.

Watch TRANSITIONING INTO THE ROBOTIC WORLD An increase in labour productivity is desired to ensure a healthy dairy business. Achieving more litres of milk per worker in an animal‑friendly way is possible with a robotic milking system. But you can not just rush out and buy a robotic milking system. There are many factors that you need to consider. In this video the topic of transitioning into the robotic world and its influences on cow management will be covered. What things need to be considered? How do we ensure we have the most successful adaptation of the technology to optimize cow health and performance? Watch this video for a look into how robotics can improve the way we manage our cows.

Listen to what other producers have to say: Top Producer Panel – Robotics conference. Join seven of the top DeLaval VMS producers from North America, Europe, Oceania and Latin America as they share and build knowledge around the DeLaval integrated robotic solution and best practices for robotic milking.

[related-posts-thumbnails]

Leave a Reply

You must be logged in to post a comment.