Discover why your milk’s ability to dissolve matters more than ever. New research on high-protein dairy powders reveals surprising challenges that could impact your farm’s bottom line. Learn how rehydration science might reshape milk markets and influence future pricing models.

Have you ever wondered what happens to your milk after it leaves the farm? For an increasing amount of milk, the journey includes transformation into specialized high-protein powders that serve key roles in everything from infant formula to protein shakes. But you might not know – these premium ingredients face a significant challenge: they’re surprisingly stubborn about dissolving in water! Recent research from the Journal of Dairy Science reveals that understanding this rehydration process is critical for maintaining the value of your milk throughout the supply chain, potentially affecting both your market opportunities and your milk check.

The Growing Importance of High-Protein Dairy Ingredients

From Farm to Global Market

You’ve probably noticed the protein boom at your local grocery store. Consumers can’t get enough protein in their diets, so they’re turning to protein bars and ready-to-drink shakes. This trend has created significant growth in the dairy protein market, with increasing demand for high-quality ingredients worldwide.

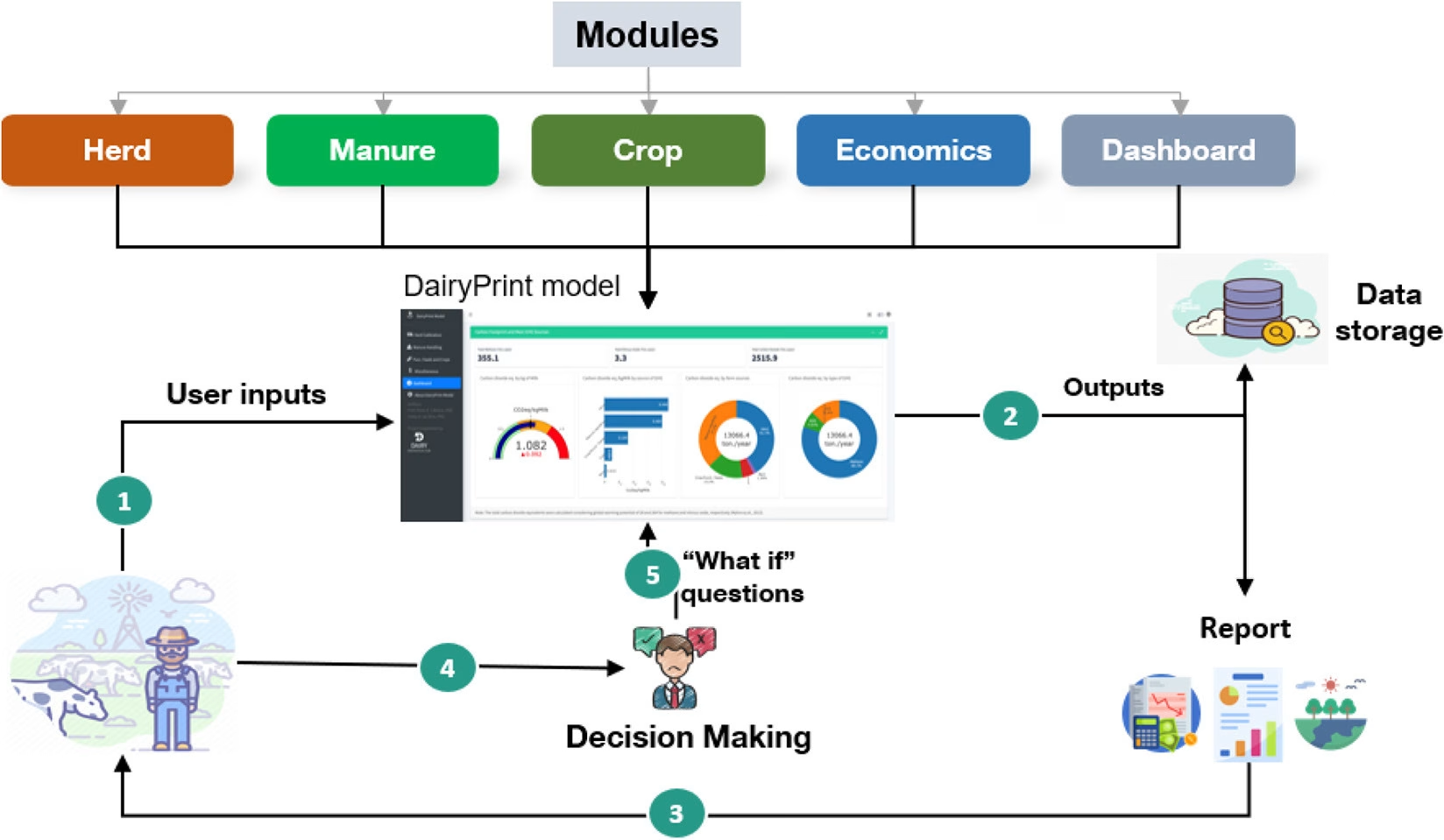

What does this mean for you as a dairy farmer? An increasing percentage of milk is being processed into specialized high-protein ingredients like milk protein concentrate (MPC), milk protein isolate (MPI), and micellar casein concentrate. These aren’t your grandparents’ milk powders – they’re sophisticated ingredients designed to deliver specific nutritional and functional benefits in food formulations.

Premium Functionality Drives Value

“These high-protein powders are beautiful due to their superior nutritional benefits like high protein and calcium content, plus functional benefits such as gelation, emulsification, and foaming properties,” explains a recent journal review by Roy and Amamcharla (2025). In plain language, these ingredients make food products taste better, look better, and deliver better nutrition – commanding premium prices.

Could the composition of your herd’s milk become even more valuable as processors better understand these functional properties? It’s a question worth considering as the industry evolves.

The Technical Challenge: When Protein Powders Won’t Play Nice With Water

The Complex Science of Dissolution

Here’s where things get interesting—and potentially problematic. These high-value ingredients face a significant technical challenge: they often dissolve poorly in water. You might think dissolving powder in water is simple, but it’s surprisingly complex for high-protein dairy ingredients.

According to Roy and Amamcharla’s research, the rehydration process involves multiple steps: wetting (water contacts the powder), sinking (particles go below the water surface), swelling (particles absorb water), dispersion (particles break apart), and dissolution (components distribute evenly). For casein-rich powders like MPC, this process can take up to 24 hours to complete fully – creating significant challenges for food manufacturers.

Real-World Impact on Processing

Think about it – no one wants those annoying clumps in their protein shake. Poor rehydration doesn’t just affect consumer satisfaction; it creates real processing headaches for manufacturers, including:

- Clogged filters and processing lines

- Loss of nutritional and functional properties

- Increased operating costs

- Potential waste of valuable dairy components

Why has the industry accepted such poor rehydration performance for so long? Could improvements in this area open entirely new applications for dairy proteins – potentially creating new markets for your milk?

What’s Happening When These Powders Hit Water?

The Tale of Two Proteins

Let’s examine what’s happening technically but in terms that make sense on the farm.

You know how different your milk components behave. Research shows that SMP (skim milk powder) and whey protein powders typically rehydrate rapidly, while casein-dominant ingredients like MPC can be much more stubborn. The difference? According to the Journal of Dairy Science review, SMP has high lactose content and more water-soluble proteins, while casein-rich powders present more challenges.

Rehydration Comparison

The table below gives you a quick comparison of how different dairy powders behave when they hit the water – and it explains a lot about why some ingredients are easier to work with than others:

REHYDRATION COMPARISON

| Product | Protein Content | Typical Rehydration Time | Key Applications |

| Skim Milk Powder | 34-37% | 15-30 minutes | Bakery, yogurt, recombined milk |

| Whey Protein Concentrate | 34-80% | 15-45 minutes | Sports nutrition, bakery |

| Milk Protein Concentrate 85 | 85% | 1-24 hours | Protein-fortified foods, cheese |

| Micellar Casein Concentrate | 80-90% | 4-24+ hours | Protein bars, medical nutrition |

The Research Details

“Whey protein powders have been reported to solubilize without undergoing the swelling step,” the research notes, while casein-rich powders must undergo a more complex process. Researchers like Dr. Jayendra Amamcharla, Director of the Midwest Dairy Foods Research Center, are working hard to understand and improve this.

“The slow and low solubility of these powders can pose difficulty in processing due to clogged filters and processing lines, leading to a loss of nutritional and functional properties and increased operating costs due to fouling,” explains the journal article.

Economic Implications: Following the Money

The Value Chain Connection

You’re probably wondering how all this technical research translates to your farm’s financial health. While the connection might not be evident at first, there are several ways this research could impact your bottom line:

- Component Valuation: As processors better understand the factors affecting powder functionality, they may emphasize specific milk composition parameters more. Could protein content, casein-to-whey ratios, or even specific protein fractions become more critical in milk pricing formulas? Could your milk check eventually include a “rehydration bonus” for specific protein profiles?

- Market Development: Improved functionality could open new markets for dairy ingredients. Food manufacturers can use these powders in more products when they work better. More applications mean more demand, which is generally good news for milk prices.

- Processing Efficiency: When processors can reduce problems with clogged equipment and lost functionality, they become more efficient and potentially more profitable. A more profitable processing sector can support higher farm milk prices in the long run.

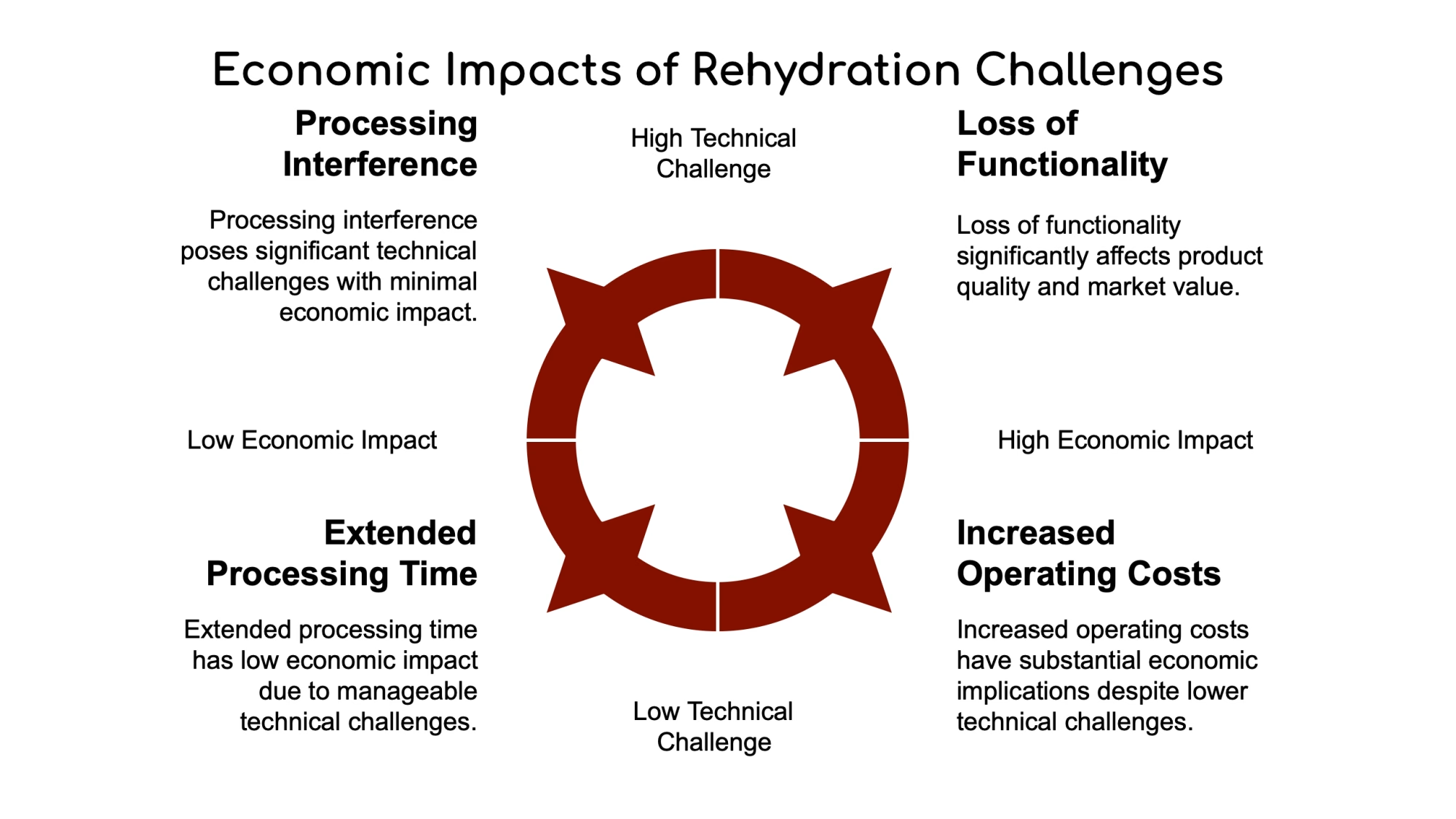

Rehydration Challenges & Economic Impacts

The following table breaks down how the technical challenges of rehydration translate into real economic consequences throughout the supply chain:

REHYDRATION CHALLENGES & ECONOMIC IMPACTS

| Challenge | Scientific Finding from Research | Economic Implication for Processors | Potential Farm-Level Impact |

| Processing Interference | “Clogged filters and processing lines” | Increased maintenance costs, reduced throughput | Potential price penalties for milk components that contribute to poor functionality |

| Loss of Functionality | “Loss of nutritional and functional properties” | Reduced product quality, customer complaints | Potential future premiums for milk that produces better-functioning ingredients |

| Increased Operating Costs | “Increased operating costs due to fouling” | Higher production expenses, reduced margins | Pressure on milk prices or component valuation |

| Extended Processing Time | “Casein-dominant ingredients can take up to 24h to fully hydrate” | Longer batch times, reduced plant efficiency | Interest in milk composition factors that affect rehydration speed |

Dairy Economics Perspective

Mark Johnson, a Wisconsin Center for Dairy Research dairy economist, notes: “As we’ve seen with specialty whey products, the more functional an ingredient becomes, the greater its market value. This same principle applies to high-protein dairy ingredients – as they become more functional and versatile, their market value increases, ultimately supporting producer milk prices.”

The Future: Research Directions and Industry Impact

Cutting-Edge Measurement Technologies

Scientists are using sophisticated methods to tackle these rehydration challenges. The research describes techniques ranging from electrical conductivity and ultrasound to imaging methods and nuclear magnetic resonance. Why all this scientific firepower? Better rehydration means better products and returns for the dairy supply chain.

MEASUREMENT TECHNOLOGIES FOR REHYDRATION ASSESSMENT

| Technology | What It Measures | Industry Application Potential | Key Finding from Research |

| Electrical Resistance Tomography | Real-time visualization of rehydration process | High (robust, low-cost) | “A robust and low-cost method offering real-time visualization of processes” |

| Focused Beam Reflectance Measurement | Particle size changes during rehydration | High (in-line monitoring) | “The rate of water diffusion was higher for low protein powders” |

| Ultrasound Testing | Sound velocity and attenuation | Medium (non-destructive) | “The velocity is dependent on the composition… the attenuation is affected by the particle size” |

| Environmental Scanning Electron Microscopy | Visualization of particle structure changes | Low (laboratory research) | “Loss of particle shape and fusion occurred at different humidity levels based on protein content” |

| Nuclear Magnetic Resonance | Molecular-level changes during hydration | Low (research only) | “Shorter decay time in nonaged samples compared with aged samples” |

One promising approach is electrical resistance tomography (ERT), described in Roy and Amamcharla’s review as “a robust and low-cost method offering real-time visualization of processes.” This technology helps processors monitor rehydration in real-time, potentially leading to better process control and improved product quality.

Key Research Findings

One ERT study notes that “the rate of water diffusion was higher for low-protein powders,” confirming that higher-protein products face more significant rehydration challenges. This insight helps processors develop better solutions.

Why does this matter to you? Because every improvement in dairy ingredient functionality potentially expands markets for your milk. As consumer demand for protein grows, these technical improvements could be the difference between dairy proteins maintaining their market advantage or losing ground to plant-based alternatives.

What This Means For Your Farm Operation

Practical Takeaways for Dairy Producers

You might think, “That’s all well and good, but how does it affect my day-to-day operation?” Fair question! Here are some practical takeaways:

Understanding Milk Component Values

As research advances, the specific composition of milk may become increasingly important. Components beyond fat and protein percentage—such as particular protein fractions or functionality—might impact milk valuation.

Engaging With Your Supply Chain

Ask questions about how your milk is used and what quality parameters matter most to the company’s products. Understanding the end-use can help you make more informed breeding, feeding, and management decisions.

Tom Wilson, a Pennsylvania dairy farmer who regularly communicates with his cooperative about milk quality, shares: “Last year, our co-op began discussing protein quality metrics beyond just percentage. After learning about how our milk was being used in their new MPC production facility, I adjusted our feeding program slightly to optimize protein composition. The premium isn’t huge yet, but having that knowledge positioned us to benefit from their new quality incentive program.”

Monitoring Industry Developments

The growing market for protein ingredients means more opportunities for your milk to be used in high-value applications. Monitoring these trends can help you position your operation for the future.

Communicating Dairy’s Value

This research reminds us that dairy is a technically sophisticated food with complex properties that create unique value. That’s something worth communicating to consumers who might otherwise view milk as a simple, commodity product.

5 QUESTIONS TO ASK YOUR CO-OP OR PROCESSOR

- How are you currently using the protein from my milk?

- What protein quality metrics matter most for your products?

- Are you developing or producing high-protein ingredients?

- Do you foresee future premiums for specific protein composition or quality?

- What breeding or management practices might help improve the value of my milk for your operations?

Conclusion: The Powder Connection To Your Profitability

Although research on the rehydration characteristics of high-protein dairy powders may seem distant from daily farm operations, it represents an essential piece of the larger puzzle of dairy’s future. Technical research that improves dairy ingredient functionality ultimately supports market development and utilization, potentially creating long-term opportunities for your farm.

Action Steps You Can Take Today

- Start a conversation with your cooperative or processor about how they evaluate protein quality and what metrics they might value in the future.

- Review your herd genetics and feeding programs with protein composition in mind.

- Stay informed about dairy ingredient research through industry publications and extension resources.

- Consider participating in industry forums or producer committees on dairy product innovation and quality.

As consumer demand for protein grows, the dairy industry’s ability to deliver functional, high-quality proteins becomes increasingly essential for maintaining and expanding market share. Understanding these downstream challenges and opportunities gives you valuable perspective on the entire value chain your milk travels through.

What’s your experience with how milk quality affects processor demands? Have you noticed changing requirements or incentives from your milk buyer related to protein content or other parameters? We’d love to hear your perspectives in the comments section below.

Remember: In today’s complex dairy landscape, knowledge about the entire value chain – from cow to consumer – is one of your most valuable assets. The better you understand how your milk is being used, the better positioned you’ll be to capture value from emerging market opportunities.

Key Takeaways

- High-protein dairy powders are valuable but face challenges dissolving in water

- Poor rehydration creates processing problems that can reduce ingredient value

- Recent research shows casein-rich powders (like MPC) can take up to 24 hours to dissolve fully

- Scientists are developing new methods to improve and measure rehydration

- These technical improvements could potentially influence milk pricing and markets

- Stay informed about protein quality parameters that might affect your milk’s value

Summary

This article explores the critical importance of rehydration properties in high-protein dairy powders and their potential impact on farm profitability. Recent research reveals that casein-rich powders, such as milk protein concentrates (MPC), face significant challenges in dissolving efficiently, leading to processing issues and reduced functionality. These technical hurdles can affect the dairy value chain, from processing efficiency to end-product quality. Understanding these downstream challenges is crucial for dairy farmers as they may influence future milk pricing models, with potential premiums for specific protein compositions or quality metrics. The article highlights cutting-edge research in measurement technologies to improve rehydration processes and discusses how these advancements could open new markets for dairy proteins, ultimately supporting milk prices. By staying informed about these developments and engaging with processors about protein quality parameters, dairy farmers can position themselves to capture value from emerging market opportunities in the growing high-protein ingredient sector.

Learn More

- Dairy Markets Brace for Winter: Surplus Cheese and Butter, Rising Whey and Milk Powder Prices

- Why 2024 Was a Game-Changer for the Protein-Packed Dairy Industry

- Global Dairy Market Shake-Up: Key Trends and Insights from December 9th, 2024 Recap

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Daily for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!