Wisconsin’s Mystic Valley Dairy shatters records with 125 pounds of energy-corrected milk daily. Discover how “doing 100 little things right” creates extraordinary results.

Ever wonder what it takes to run a dairy farm where cows produce a staggering 125 pounds of energy-corrected milk daily? I recently had the chance to dive into the world of Mystic Valley Dairy, and let me tell you, what Mitch Breunig has created there is nothing short of impressive. Tucked away in the rolling hills near Sauk City, Wisconsin, this operation isn’t just succeeding—it’s crushing it.

Those production numbers aren’t a typo, folks. We’re talking 125 pounds of energy-corrected milk (ECM) and 8.4 pounds of fat and protein per cow daily, with a remarkably low 20% turnover rate. Their production efficiency is exceptional, with current components averaging an impressive 4.5% fat and 3.4% protein. But here’s what struck me most during my conversation with Mitch—there’s no magic bullet. His philosophy? “Doing 100 little things right as opposed to something magic.” That approach has turned Mystic Valley into more than a successful farm; it’s an industry powerhouse stretching far beyond its 1050 acres.

From UW-Madison to World-Class Dairy: Mitch’s Journey to Excellence

You can’t talk about Mystic Valley without getting to know the guy steering the ship. Mitch Breunig grew up on the farm his parents started in 1961, but he didn’t rely on handed-down knowledge. He headed to UW-Madison, graduating with a dairy science degree in 1992, then spent a year with Land’O Lakes in their feeding division before returning home.

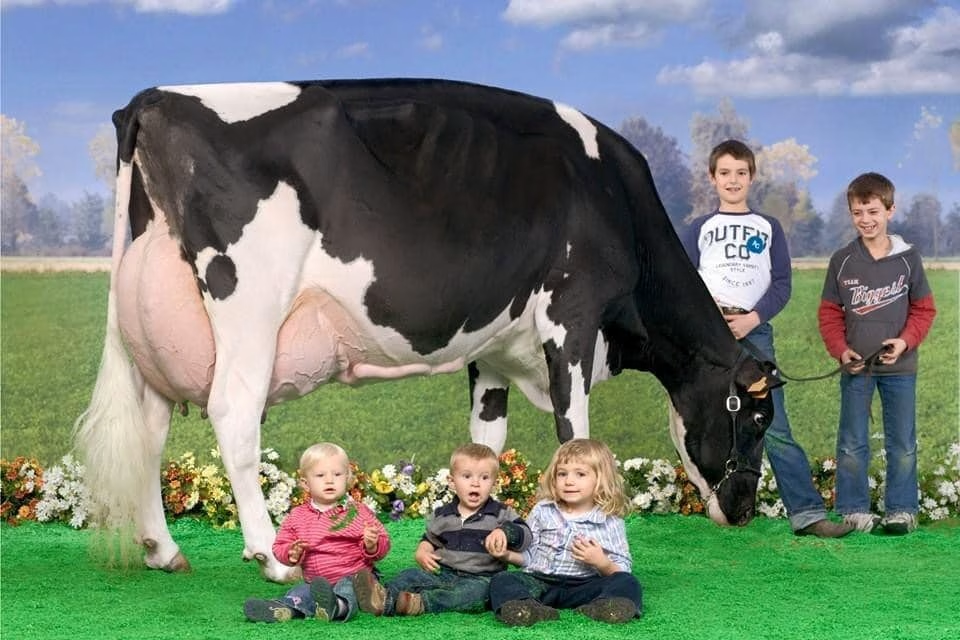

Today, he’s running a herd of about 450 registered Holsteins that have put the Jenny-Lou prefix on the map worldwide. If you’re into dairy genetics, you’ve probably heard of Toystory—yep, that’s their bull, the only one in history to sell two million units of semen. Pretty mind-blowing, right?

I found it fascinating how Mitch balances his farm life with community involvement. The guy somehow finds time to broadcast Sauk Prairie High School football and basketball games! It’s that connection to the community that keeps him grounded.

When we talked about the next generation, his eyes lit up: “There’s nothing more fulfilling than seeing them take an interest in how things are progressing daily and being excited about the animals they have worked with.” You can feel his passion for creating a legacy about more than just milk production numbers.

The Not-So-Secret Secrets to Record-Breaking Production

So, what’s happening at Mystic Valley? Which has these cows producing like champions? I asked Mitch directly, and his answer was refreshingly straightforward—it all comes down to “the basics of cow comfort and a good environment.”

Take a look at these numbers:

| Production Metric | Current Performance | Future Goal |

| Energy-Corrected Milk (ECM) | 125 lb/cow | 130 lb/cow |

| Combined Fat + Protein | 8.4 lb/cow | 9.0 lb/cow |

| Fat Percentage | 4.5% | 4.4% |

| Protein Percentage | 3.4% | 3.4% |

| Peak Milk (3rd+ lactation) | 152 lb/cow | – |

| Turnover Rate | 20% | – |

| Feed Efficiency | 1.90 lb ECM/DM | – |

The farm runs a 6-row barn stocked at 120% for stalls and 150% for headlocks. But here’s where Mitch got clever—he designed the stalls to fit older cows properly. “When we fixed this, we added a lot of productive life to our herd,” he told me. It seems obvious in hindsight, but too many barns are built assuming a 40% cull rate and don’t accommodate senior cows’ needs.

His approach to culling particularly struck me. “First of all, you want to get away from involuntary culls, cows that die, get injured, abort or are low production to voluntary culls,” he explained. This gives them control over which animals leave the herd. “The art is selling the cow when she is at maximum value before she loses cull value and doesn’t give enough milk to pay her way.” He calls it “more art than protocol,” and that kind of intuitive management seems to be a hallmark of the operation.

The Perfect Recipe: A 70-30 Forage Mix That Powers Production

You can’t get 125 pounds of energy-corrected milk without seriously dialed-in nutrition. At Mystic Valley, they’re running a high-forage diet that might surprise some folks:

| Feed Component | Percentage | Additional Notes |

| Corn Silage | 70% | 3-way blend of BMR and conventional hybrids |

| Low Lignin Alfalfa | 30% | HarvXtra variety |

| Target Refusals | 2-3% | Refusals fed to dry cows and heifers |

What caught my attention was their use of a 3-way blend of BMR and conventional hybrids in their corn silage. Mitch said, “Since using both of these, our consistency is very high, and feed transitions are smoother.” Smart move—why commit to just one variety when a blend gives you more stability?

His nutritionist made an interesting observation I hadn’t considered before: Mystic Valley cows have greater capacity—not just taller frames, but can maintain production even when forage quality fluctuates because they can pack away more dry matter than other herds. That kind of genetic selection pays dividends daily at the feed bunk.

They’re targeting an impressive 1.90 pounds of energy-corrected milk per pound of dry matter. For those not neck-deep in dairy metrics, that’s seriously efficient feed conversion.

A Day in the Life: Routine Is King at Mystic Valley

So, what does a typical day look like when you’re producing these kinds of numbers? Consistency, consistency, consistency.

The herd is milked three times daily, and Mitch is militant about minimizing time away from the pen and keeping lock-up periods short. “I am a big believer in time away from the pen being limited as well as lock-up time being very short,” he emphasized. It makes sense—every minute a cow spends standing in a holding area is a minute she’s not resting, ruminating, or eating.

They use the TAP feed system, which delivers a consistent diet daily. One thing I appreciated was how they handle refusals—instead of being wasted, they’re fed to dry cows and heifers. That kind of resource efficiency is an innovative dairy business.

Throughout the day, the team monitors key performance indicators using activity and rumination sensors. It’s not about replacing human observation but enhancing it with technology that can spot subtle changes before they become problems.

Breeding for Balance: How Mystic Valley Built 115 Lifetime Production Stars

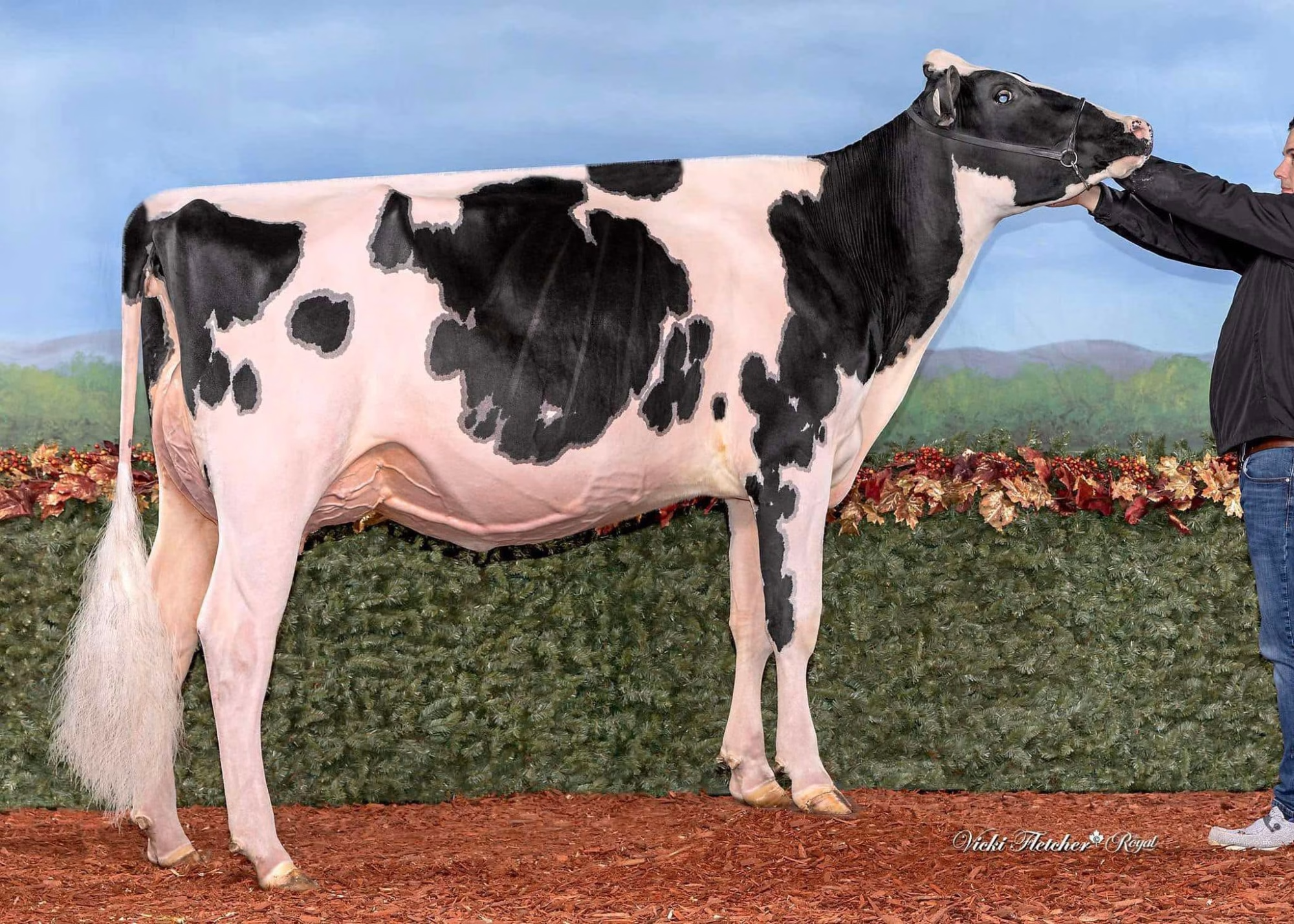

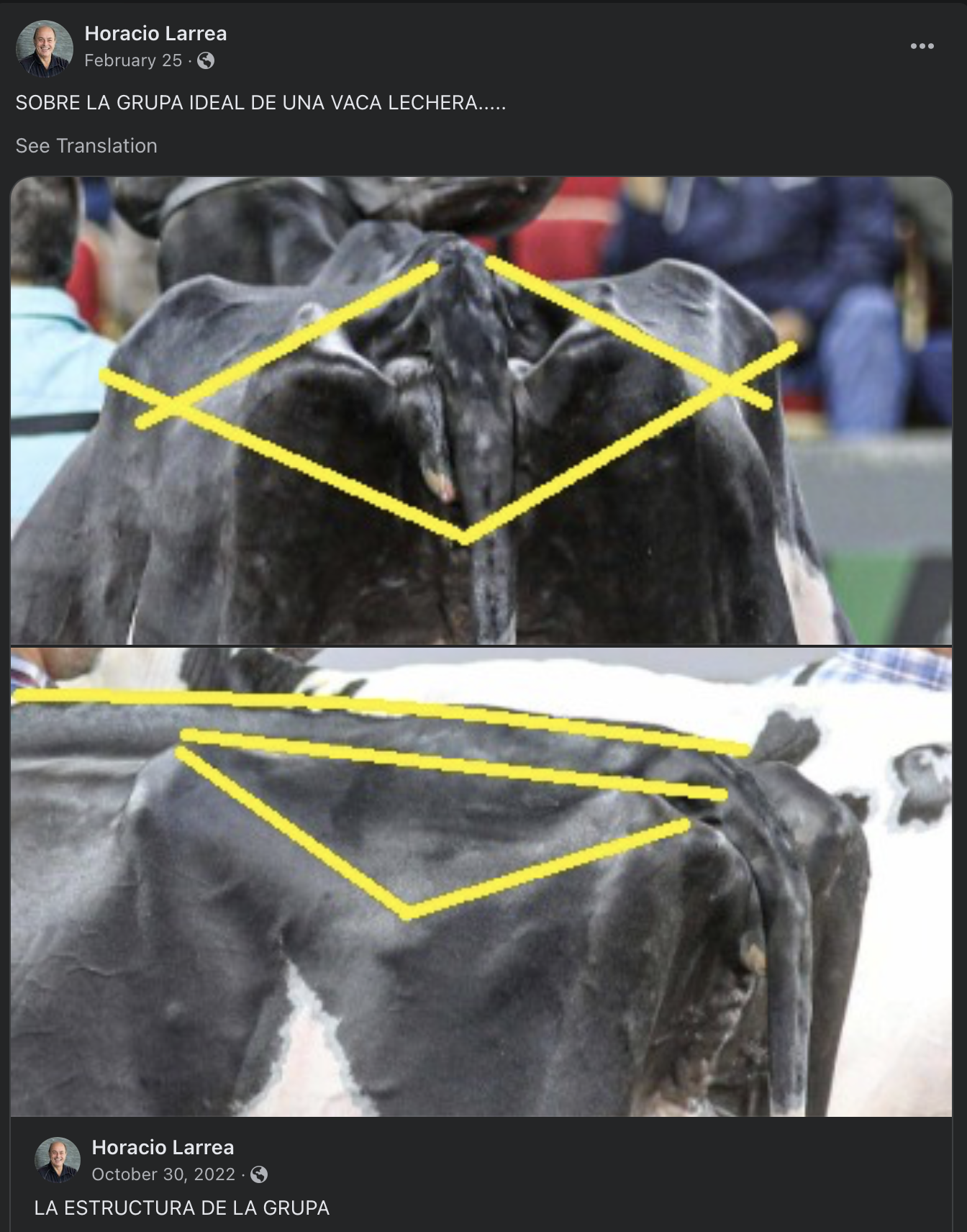

Many farms chase extremes in their breeding programs, but Mitch takes a different approach: “We breed for balance. Conformation is still important, especially when you have older cows.”

While they want high combined fat and protein (CFP) bulls, they insist on balanced fat and protein contribution. As Mitch put it, “The ebbs and flows of milk pricing are too hard to predict, so we want to be strong in both.” They also prioritize mastitis resistance, fertility, and livability.

Check out the daughter groups they’ve built:

| Bull Name | Number of Daughters in Herd | Notable Characteristics |

| Parfect | 65 | – |

| Conway | 40 | – |

| Sheepster (Trooper son) | 40 | Renegade grandson |

| Gameday | 30 | – |

| Renegade | – | Significant influence as foundation sire |

The farm primarily uses NxGen bulls from Select Sires, focusing on high TPI sires that excel across multiple indexes.

“A key partner in this genetic success is Kevin Jorgensen from Select Sires,” Mitch notes. “Kevin has been instrumental in guiding our sire selections for years. We co-own several cows, which deepened our collaborative approach to breeding decisions. His expertise has been invaluable in building the genetic foundation we rely on today.”

Their commitment to building daughter groups, even in the genomic era, stood out to me. “Before genomics, we tried to use bulls we liked and made 50 daughters of them. It is a lot harder to do that using genomic sires, but with a bull like Parfect, we were able to have 65 daughters and Conway 40 daughters, which has us excited for the future,” Mitch shared.

The results speak for themselves—115 cows in the herd have surpassed 150,000 pounds of lifetime production. To put that in perspective, a cow typically needs at least five lactations to hit that mark, well beyond the industry average of less than 3. Now that’s longevity!

Fresh Cow Magic: The 7-Step System That Sets Up Success

If you ask me, transition cow management might be the most underrated aspect of dairy success. At Mystic Valley, they’ve turned it into a science:

| Timing | Protocol/Intervention |

| Pre-calving | Anion-cation balance with urine pH monitoring |

| At calving | Just-in-time movement to calving area |

| Immediately post-calving | 5 gallons warm water calcium drink |

| Morning after calving | Bovicalc bolus |

| Throughout transition | Ca-vital bolus for rumination |

| Monitoring | Activity sensors for early intervention |

| Intervention if needed | BHBA checks, alfalfa meal mix, rumastart boluses |

What I found particularly interesting was their switch to a newer bolus. “Recently, we are using a different bolus called ca-vital, which is less expensive and effective at getting rumination to take off,” Mitch explained. That’s the kind of continuous improvement that keeps top herds at the summit—they’re never satisfied with “good enough.”

The system works remarkably well, with third-lactation and older cows averaging 152 pounds at peak milk. That’s about 50% higher than what you’d see in an average herd. Impressive stuff.

A Team Approach: The People Behind the Production

You might think technology drives operations like Mystic Valley, but at the end of the day, it’s all about people. The farm employs eight full-time staff members, including Mitch, plus one part-time feeder.

One thing that resonated with me was Mitch’s leadership style: “I believe in training how we want it done and then letting people do their job. You must also show what we value as the most important things and consistently coach people to do them better.”

Mystic Valley has created stability through respect and clear expectations in an industry plagued by labor shortages and high turnover. As Mitch put it, “I like to work alongside my employees to show them I am not asking for something I am not willing to do myself.” No wonder they’ve maintained consistent staffing when many farms struggle.

Marketing Elite Genetics: How Mystic Valley Sells 140 High-Quality Cows Annually

The farm’s genetic excellence creates another revenue stream through the annual sale of approximately 140 young milking cows. These animals, primarily first and second-lactation cows fresh between 15-60 days, are sold a trailer load at a time.

“The marketing side of our operation wouldn’t be nearly as successful without Kevin Jorgensen’s involvement,” Mitch explains. “Beyond his role in our breeding program, Kevin helps market our cows to potential buyers. His industry connections and understanding of what makes our genetics valuable in the marketplace have been crucial to developing this additional revenue stream.”

Mitch’s approach to marketing reflects his overall philosophy of quality: “I try to sell cows I would want to milk myself, so it is important to calve in the best animals we can because we end up keeping the ones others don’t want to buy.”

The marketing strategy employs a selective approach that respects the buyer’s interests and fair market value. “Currently, I will give a choice of a group of 35 or so to pick 15 at a predetermined price,” Mitch explained. “It is important to know the market and price accordingly.”

The recent trend of beef-on-dairy breeding has significantly impacted the market in ways that benefit operations like Mystic Valley Dairy. “The influence of beef on dairy has been huge for us as the shrinking heifer population has increased demand and prices,” Mitch notes. This market dynamic has created additional revenue opportunities that help offset periods of tight margins in milk production.

Navigating Challenges: How Mystic Valley Handles Industry Headwinds

Let’s be honest—dairy farming isn’t all sunshine and record production. Mitch identifies labor and inflation as two significant hurdles facing elite operations like his.

His approach? “As the cost of production goes up, you can either spend less or improve margin through better output.” Rather than slashing costs, which can backfire by reducing productivity, they focus on improving efficiency to maintain margins even when expenses climb.

One fascinating strategy they’ve developed is using cattle sales as a financial safety net. “The ability to market cattle has been a game changer for us; when margins get tight, we can find additional revenue,” Mitch explained. They sell about 140 young milking cows annually, primarily first—and second-lactation animals fresh for 15-60 days.

I appreciated his candor about succession planning, which he admits is “our biggest weakness.” He’s focused on encouraging outside experience with relatively young children: “I think it’s important to get experience outside of our farm to bring back a different perspective than how Dad and Grandpa have always done it.” He doesn’t want them to feel obligated to return—the passion has to be genuine.

Setting the Bar Higher: Mystic Valley’s Future Goals

Even with their current stellar performance, Mitch isn’t sitting still. “Our next goal is 9 pounds of CFP per cow daily,” he told me, with an energy-corrected milk target of 130 pounds.

They focus on energy-corrected milk (ECM) rather than straight milk production. “We look at ECM of each cow more than straight milk production as it tends to rerank the cows considerably,” he explained. Their current components of 4.5% fat and 3.4% protein already demonstrate their commitment to high-value milk production rather than just volume.

Mitch acknowledges the biggest hurdle is the sheer energy demand of that production level, particularly in first-lactation animals where exceeding 7 pounds of CFP is challenging. But if there’s a farm that can crack that code, my money’s on Mystic Valley.

The Mystic Valley Philosophy: 100 Little Things Done Right

After understanding Mystic Valley’s approach, I realized there isn’t any single practice or innovation. It’s their comprehensive system where science-based management meets attentive animal husbandry. Mitch says, “We just want to do things well.”

That straightforward philosophy has created something remarkable—not just 125 pounds of energy-corrected milk (with an impressive 4.5% fat and 3.4% protein) and 8.4 pounds of fat and protein per cow daily with a 20% turnover rate, but a sustainable operation that’s influencing the industry while staying rooted in Wisconsin’s rich dairy tradition.

What Mitch and his team have built at Mystic Valley Dairy isn’t just impressive—it’s inspirational. They’ve shown that elite production can go hand in hand with cow longevity, that innovative practices can complement traditional values, and that doing “100 little things right” can add up to world-class results.

And isn’t that the essence of excellent dairy farming? The daily commitment to excellence, the constant refinement of practices, and the balance of science with animal husbandry. Mystic Valley isn’t just producing exceptional milk—they’re creating a blueprint for dairy success that others would be wise to follow.

Key Takeaways

- Mystic Valley’s production excellence (125 lb ECM, 4.5% fat, 3.4% protein) comes from prioritizing cow comfort, including properly sized stalls for older cows and minimizing time away from pens.

- Their nutrition program features a strategic 70-30 mix of corn silage (using a 3-way blend of BMR and conventional hybrids) and low lignin alfalfa, achieving 1.90 pounds of ECM per pound of dry matter.

- The breeding philosophy emphasizes balance rather than extremes, focusing on combined fat and protein while maintaining strong conformation, mastitis resistance, and fertility.

- A comprehensive 7-step fresh cow protocol, including specialized calcium supplementation and monitoring, helps third-lactation and older cows achieve peak milk of 152 pounds.

- The farm’s success demonstrates that elite production can coexist with exceptional cow longevity when management focuses on consistent execution of fundamentals rather than seeking a single “magic bullet.”

Executive Summary

Mystic Valley Dairy, operated by Mitch Breunig near Sauk City, Wisconsin, has achieved remarkable production metrics with their 450 registered Holsteins producing 125 pounds of energy-corrected milk daily with impressive 4.5% fat and 3.4% protein components. Their success stems from a comprehensive approach focusing on cow comfort, balanced nutrition using a 70-30 forage mix, strategic breeding for balanced traits, and meticulous fresh cow management. Rather than relying on a single “magic bullet,” Breunig attributes their extraordinary results to “doing 100 little things right,” creating a sustainable operation with exceptional longevity (115 cows exceeding 150,000 pounds lifetime production) and a low 20% turnover rate. This philosophy extends to their team management, marketing strategy for selling 140 high-quality cows annually, and ambitious future goals of reaching 9 pounds of combined fat and protein daily.

Join the Revolution!

Join the Revolution!

Join over 30,000 successful dairy professionals who rely on Bullvine Daily for their competitive edge. Delivered directly to your inbox each week, our exclusive industry insights help you make smarter decisions while saving precious hours every week. Never miss critical updates on milk production trends, breakthrough technologies, and profit-boosting strategies that top producers are already implementing. Subscribe now to transform your dairy operation’s efficiency and profitability—your future success is just one click away.

Join the Revolution!

Join the Revolution!

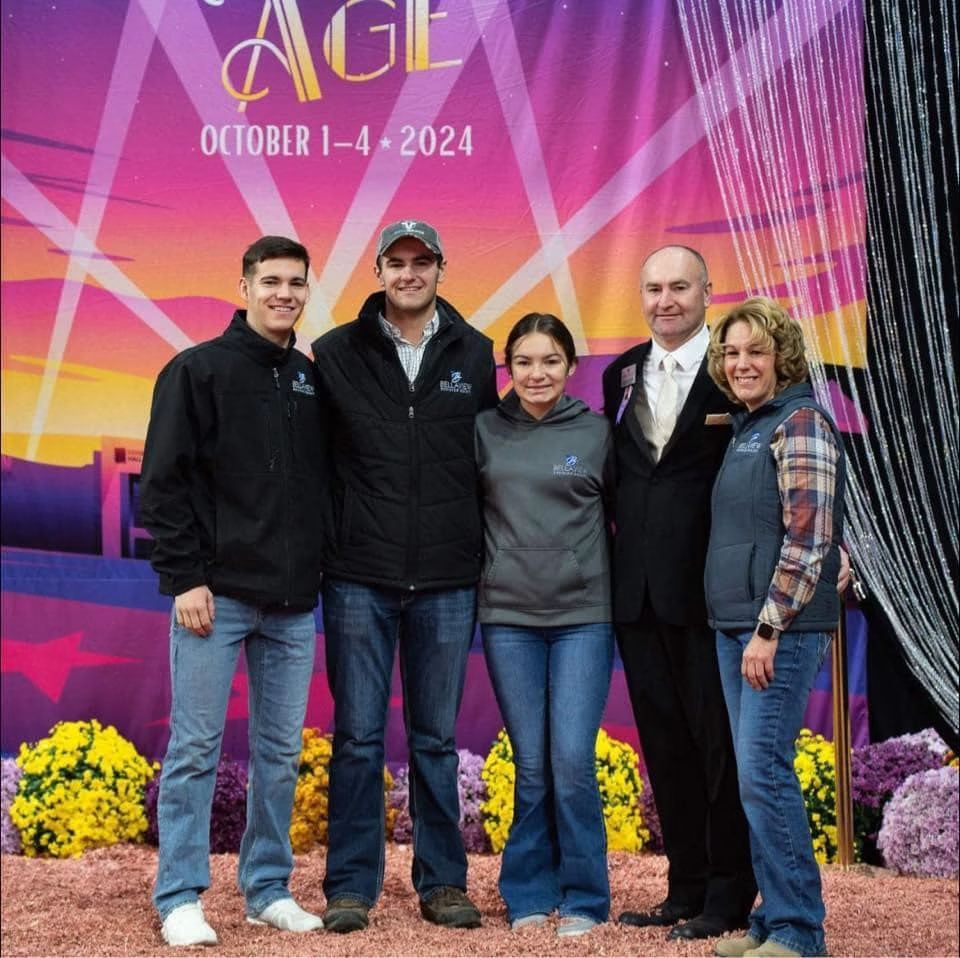

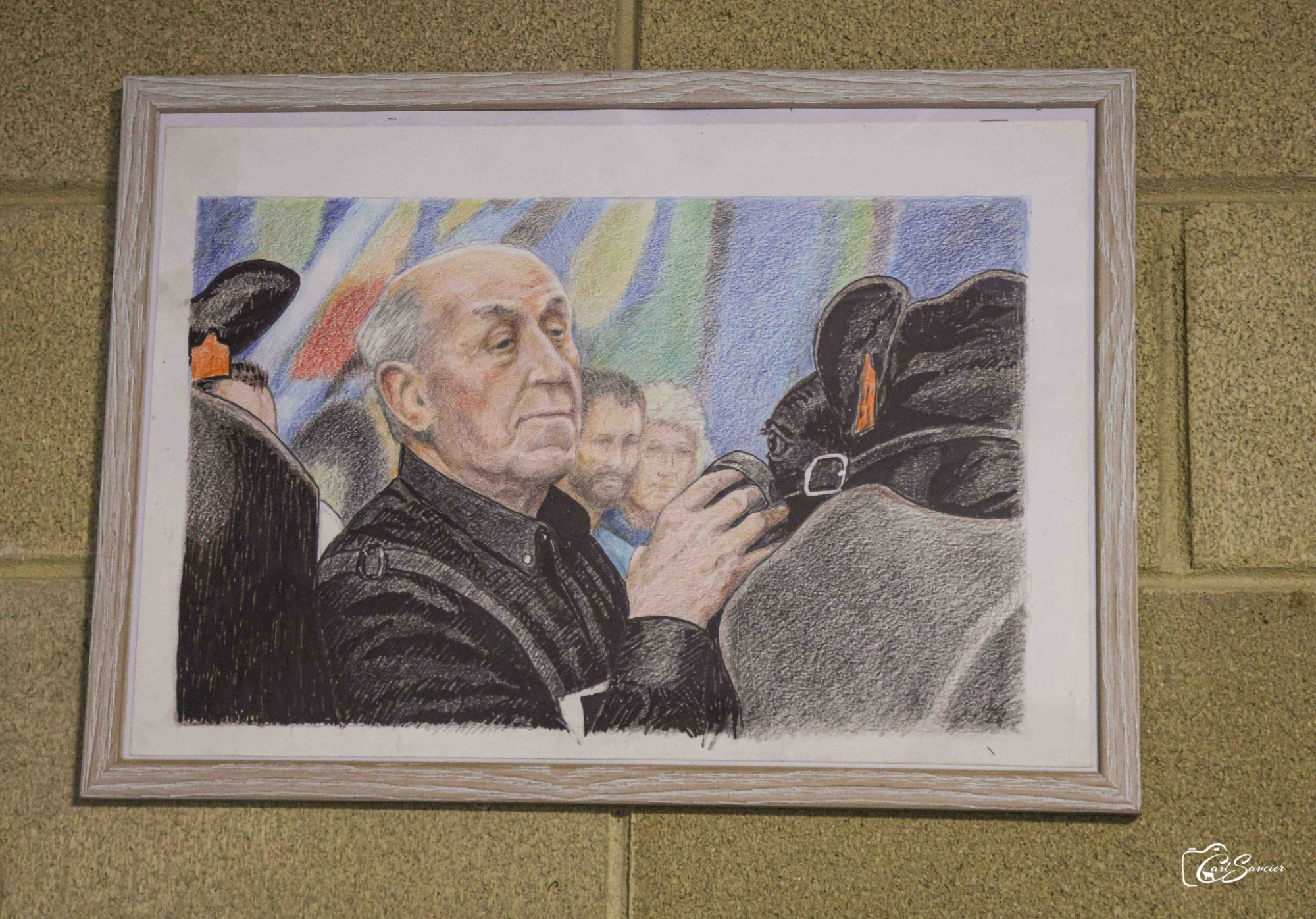

With a firm handshake that reaches your soul and an unwavering commitment to making every interaction count, Bob Hagenow has spent four decades transforming the dairy industry through genuine connections and servant leadership. Growing up on a registered Holstein farm located south of Green Bay, Wisconsin, Bob learned early that success comes from helping others succeed. Whether he’s in the World Dairy Expo show ring, where he’s served as ring steward for 40 years, mentoring young professionals, or solving complex farm challenges, Bob approaches each interaction with the same level of care and attention that has made him one of the industry’s most trusted voices. His philosophy is simple yet profound: “If you don’t have people stepping up, if you don’t have vibrant organizations adding to a community, you don’t have a community.”

With a firm handshake that reaches your soul and an unwavering commitment to making every interaction count, Bob Hagenow has spent four decades transforming the dairy industry through genuine connections and servant leadership. Growing up on a registered Holstein farm located south of Green Bay, Wisconsin, Bob learned early that success comes from helping others succeed. Whether he’s in the World Dairy Expo show ring, where he’s served as ring steward for 40 years, mentoring young professionals, or solving complex farm challenges, Bob approaches each interaction with the same level of care and attention that has made him one of the industry’s most trusted voices. His philosophy is simple yet profound: “If you don’t have people stepping up, if you don’t have vibrant organizations adding to a community, you don’t have a community.”

From her modest origins in Plain City, Ohio, Shirley Kaltenbach started a career that would make her a significant player in the artificial insemination business. As she prepares for retirement, her path shows diligence, commitment, and a relentless love of her industry and the people she works with. A lifelong learner, she has navigated several responsibilities at Select Sires over almost four decades, each adding to her remarkable legacy.

From her modest origins in Plain City, Ohio, Shirley Kaltenbach started a career that would make her a significant player in the artificial insemination business. As she prepares for retirement, her path shows diligence, commitment, and a relentless love of her industry and the people she works with. A lifelong learner, she has navigated several responsibilities at Select Sires over almost four decades, each adding to her remarkable legacy.

”SHAKIRA STOOD OUT FROM THE REST FROM THE BEGINNING”

”SHAKIRA STOOD OUT FROM THE REST FROM THE BEGINNING”

“SHAKIRA’S STAR TREK”

“SHAKIRA’S STAR TREK”