April 17th, 2025 @ Victoriaville QC

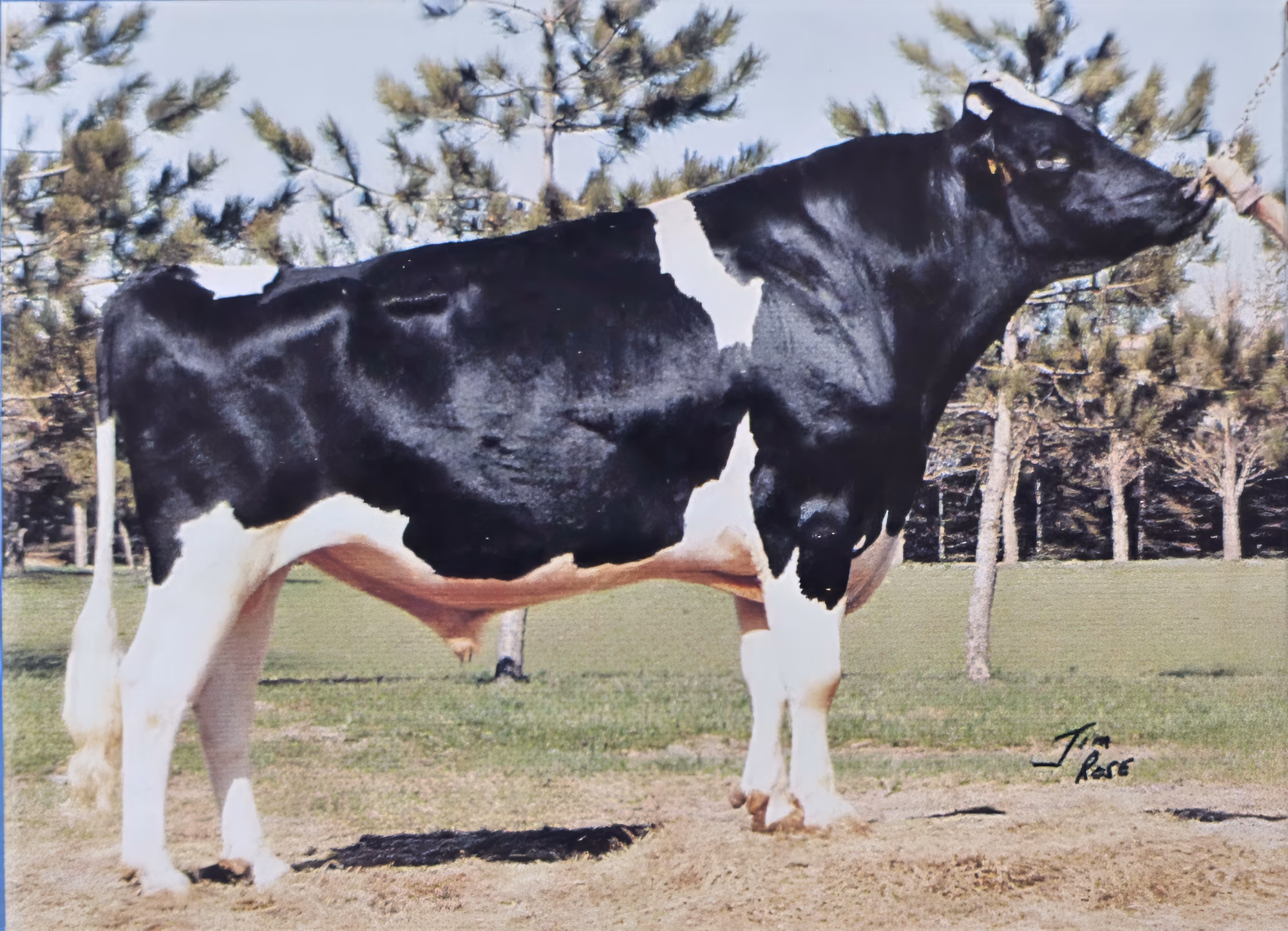

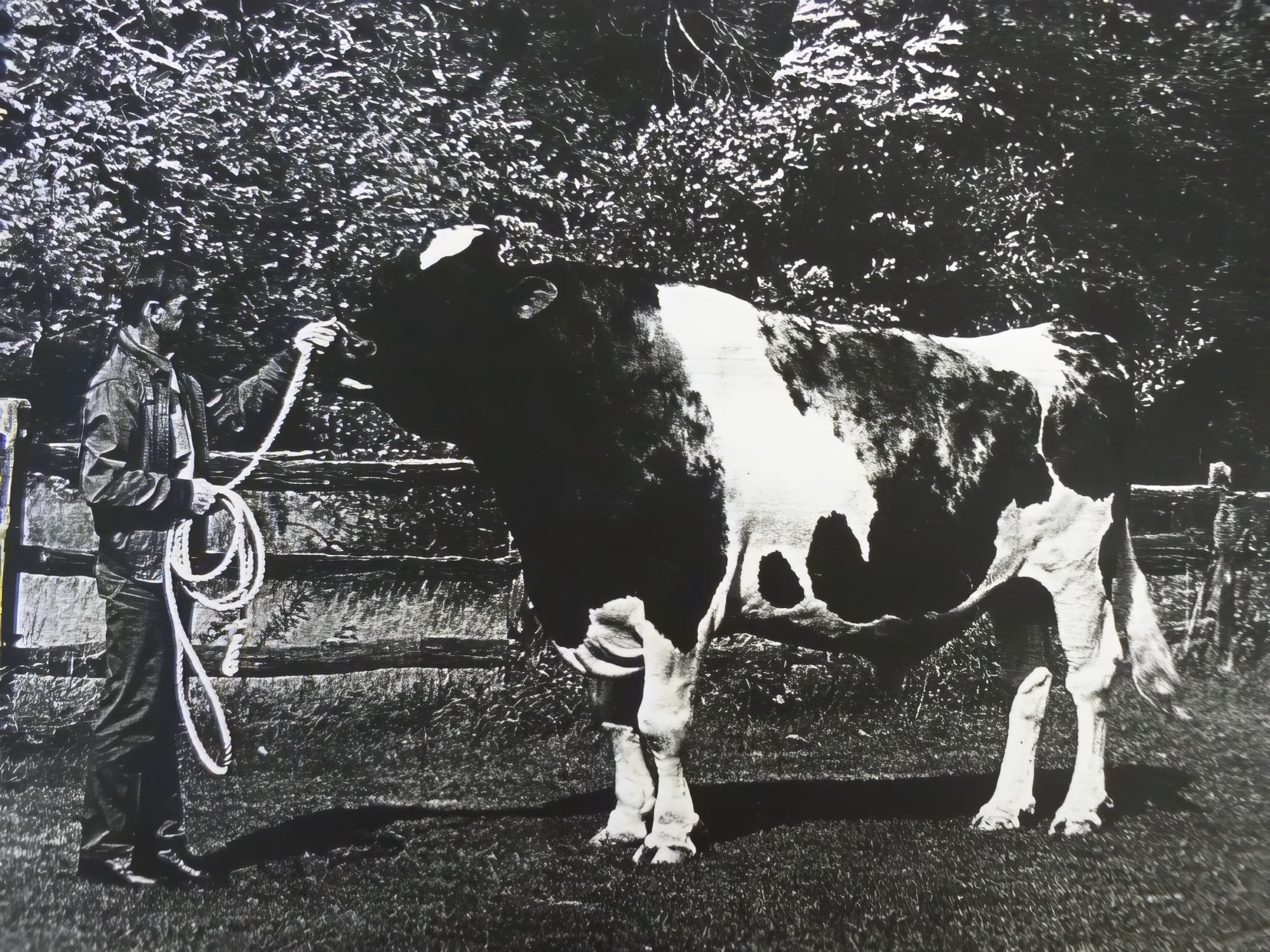

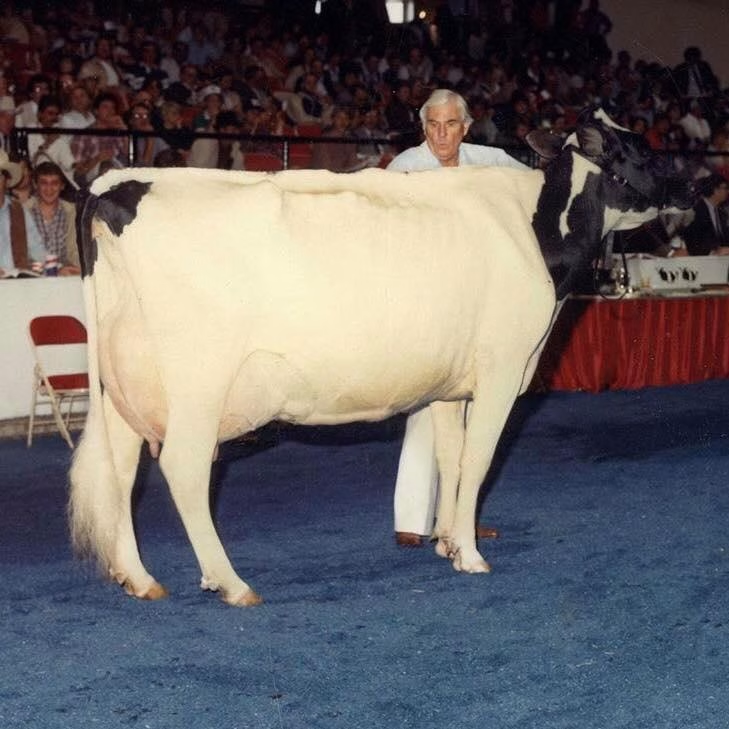

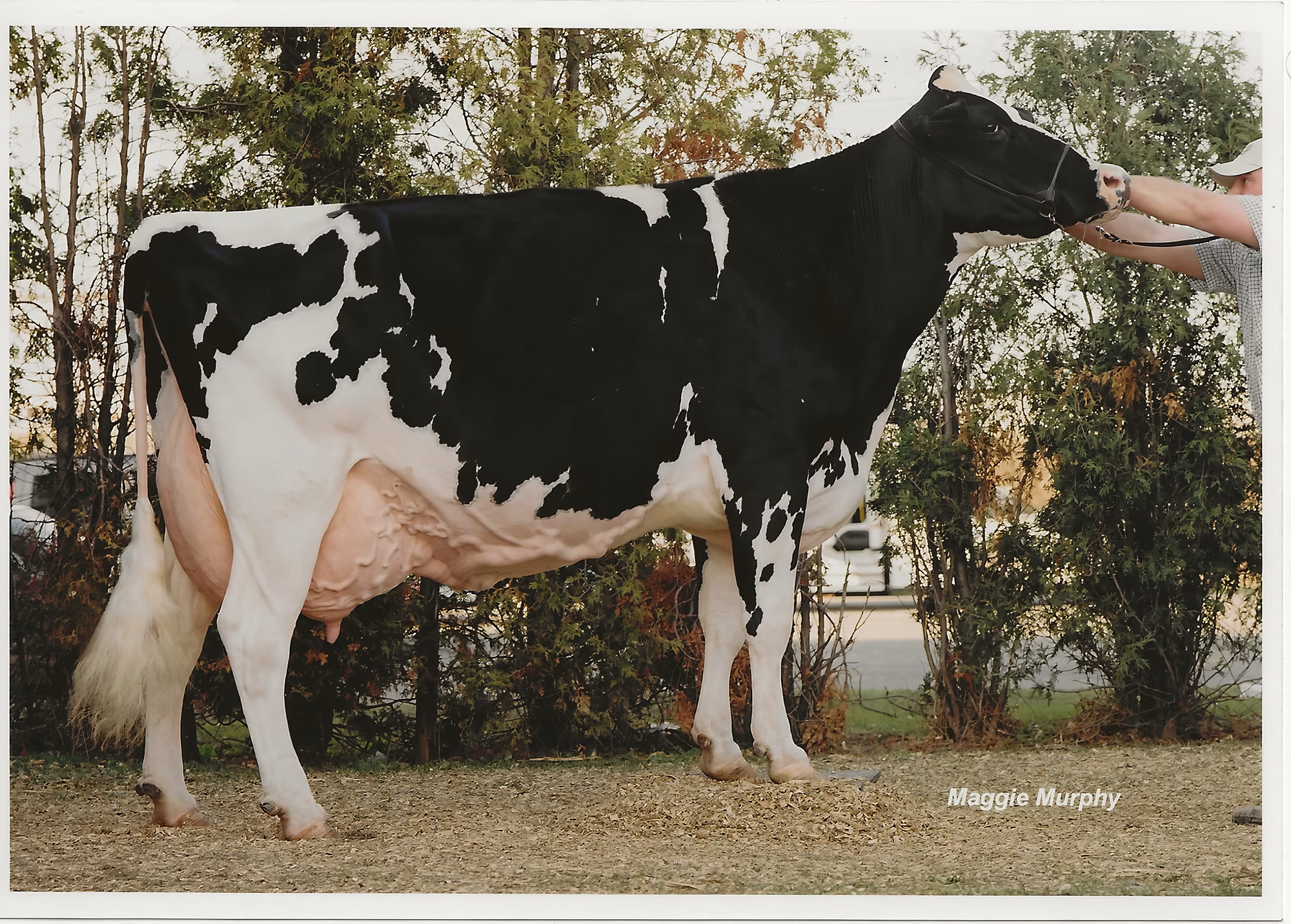

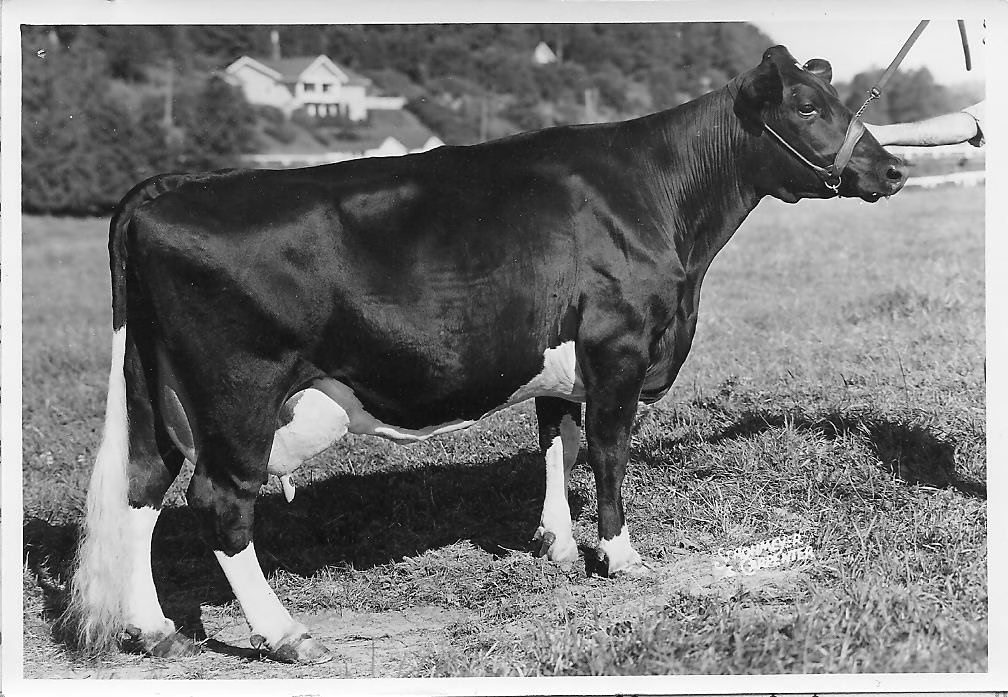

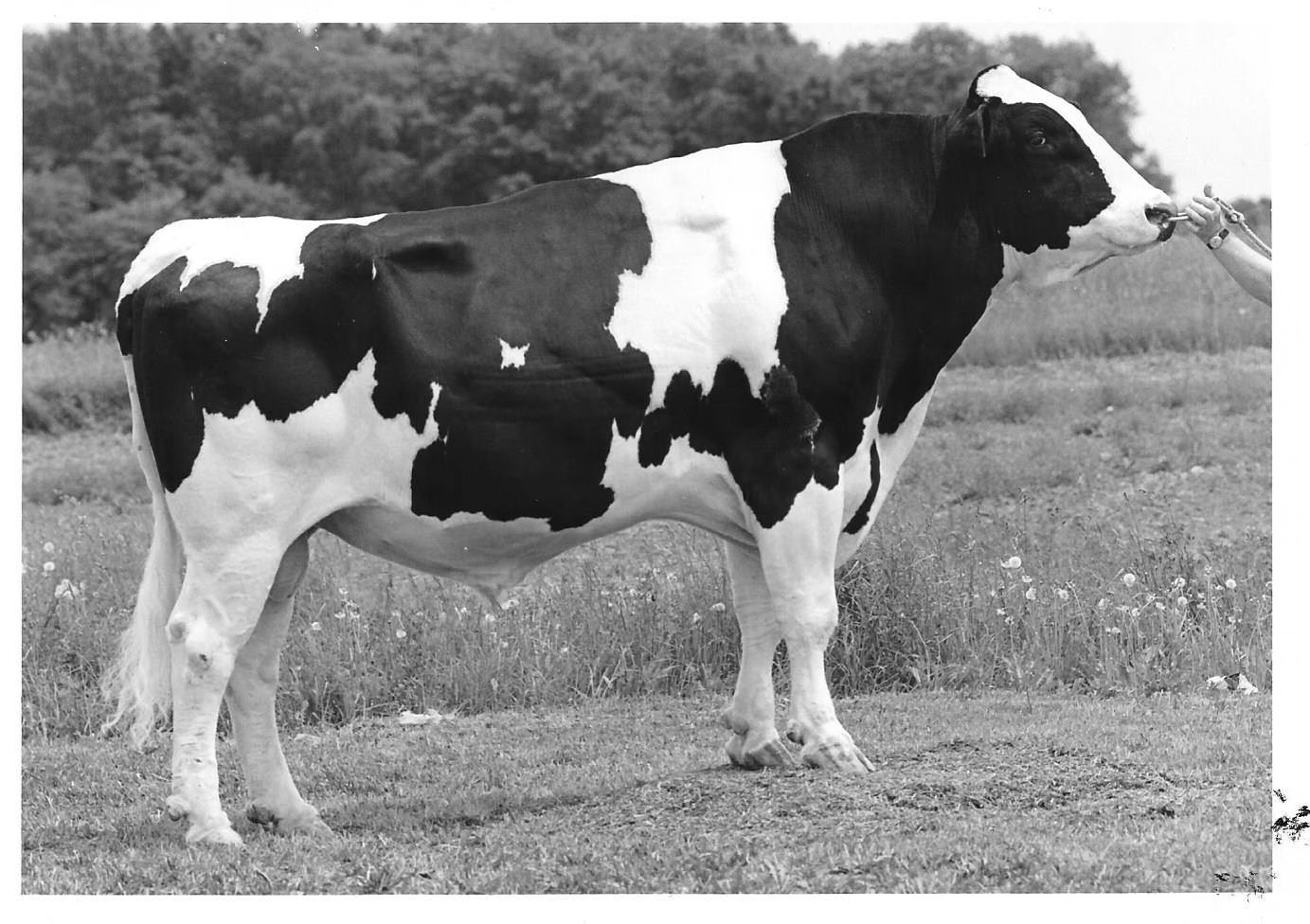

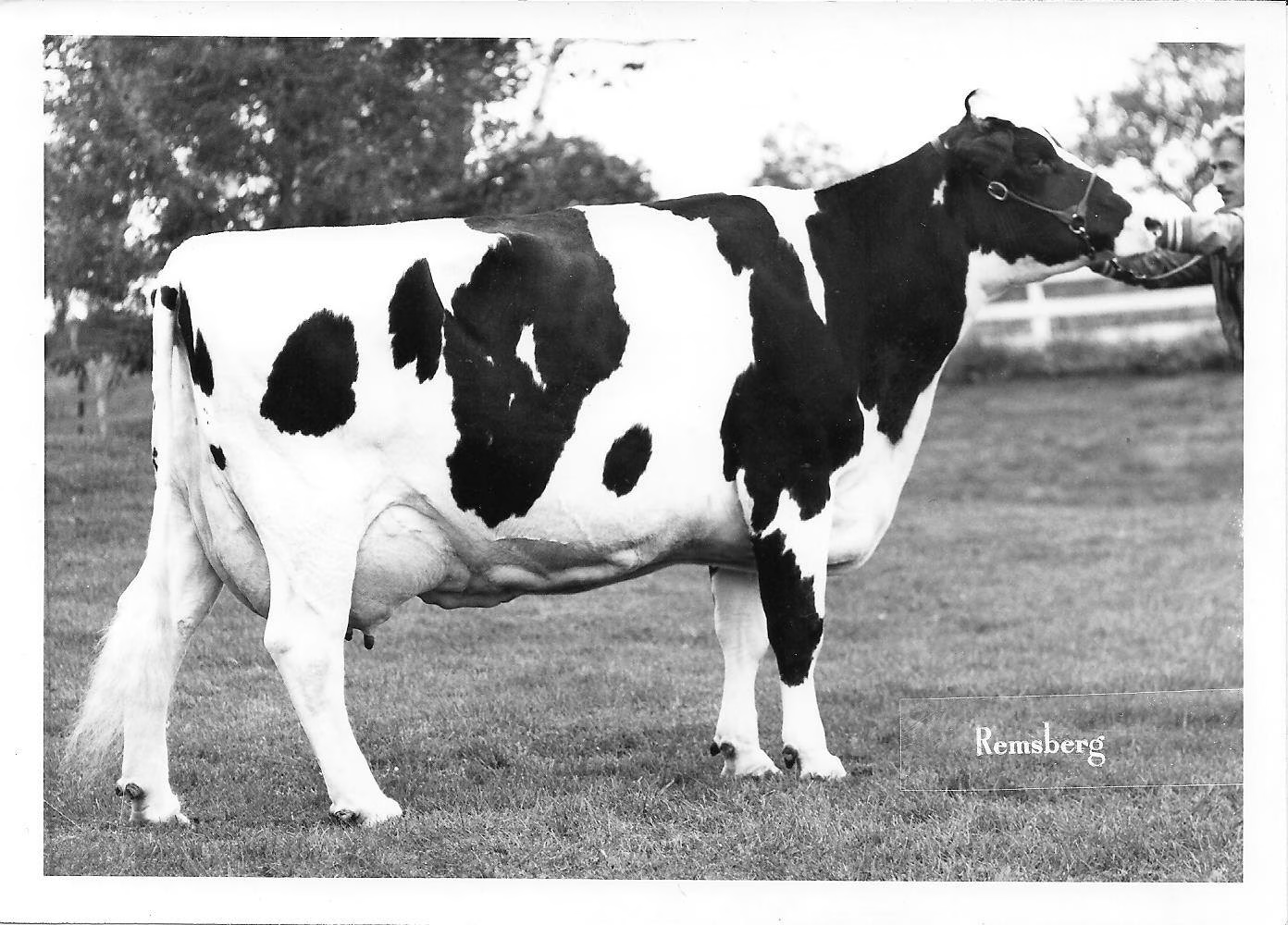

Grand Champion

Grand – PIERSTEIN DEVOUR ROSHA – PIERRE BOULET, MONTMAGNY, QC

Reserve – JACOBS UNIX CARFUL – FERME JACOBS INC, CAP SANTE, QC

HM – SICY IMPRESSION GABE – FERME BLONDIN, JEAN-PHILIPPE PROULX, JM VALLEY HOLSTEIN, PIERRE BOULET, SAINT-PLACIDE, QC

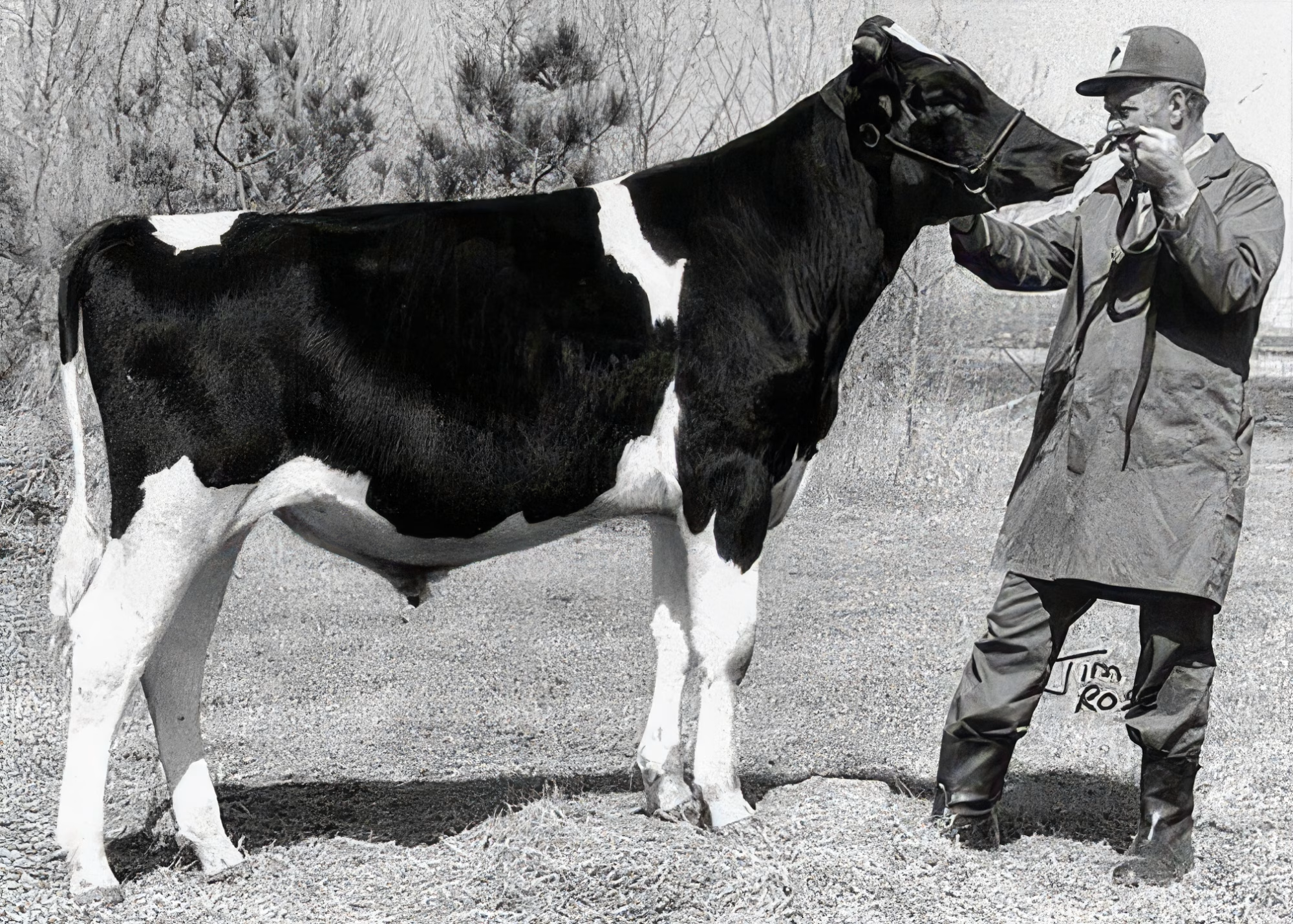

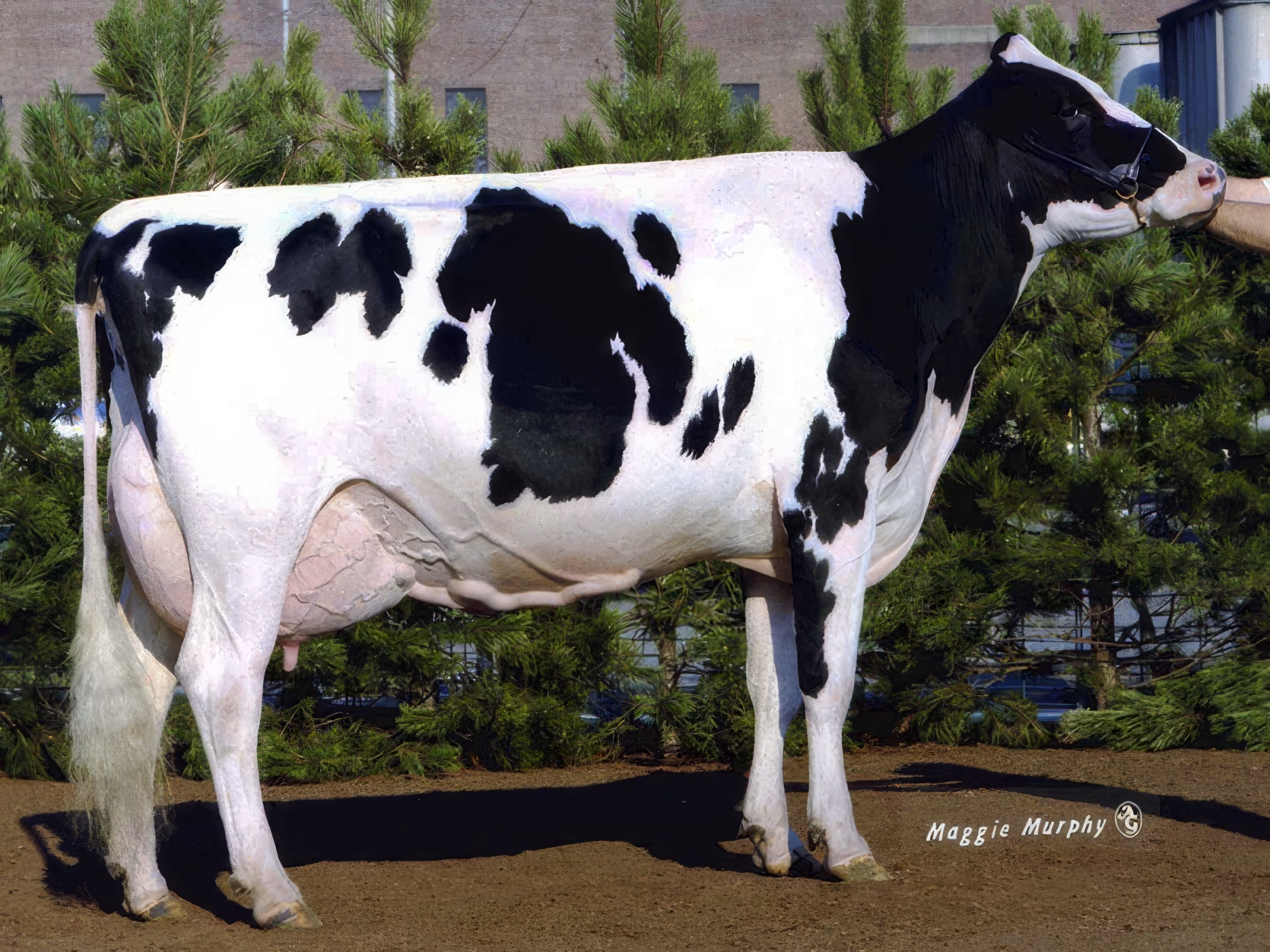

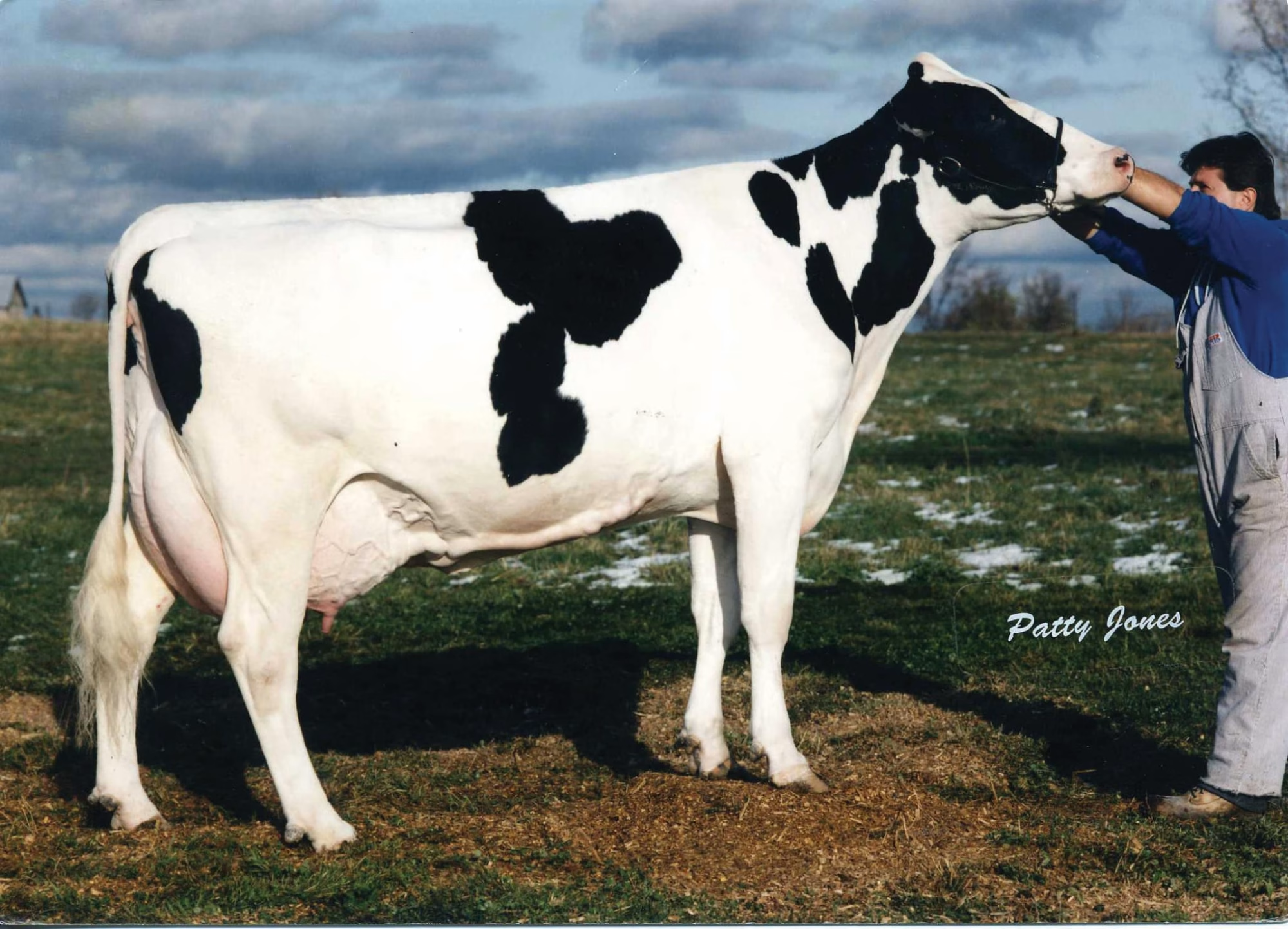

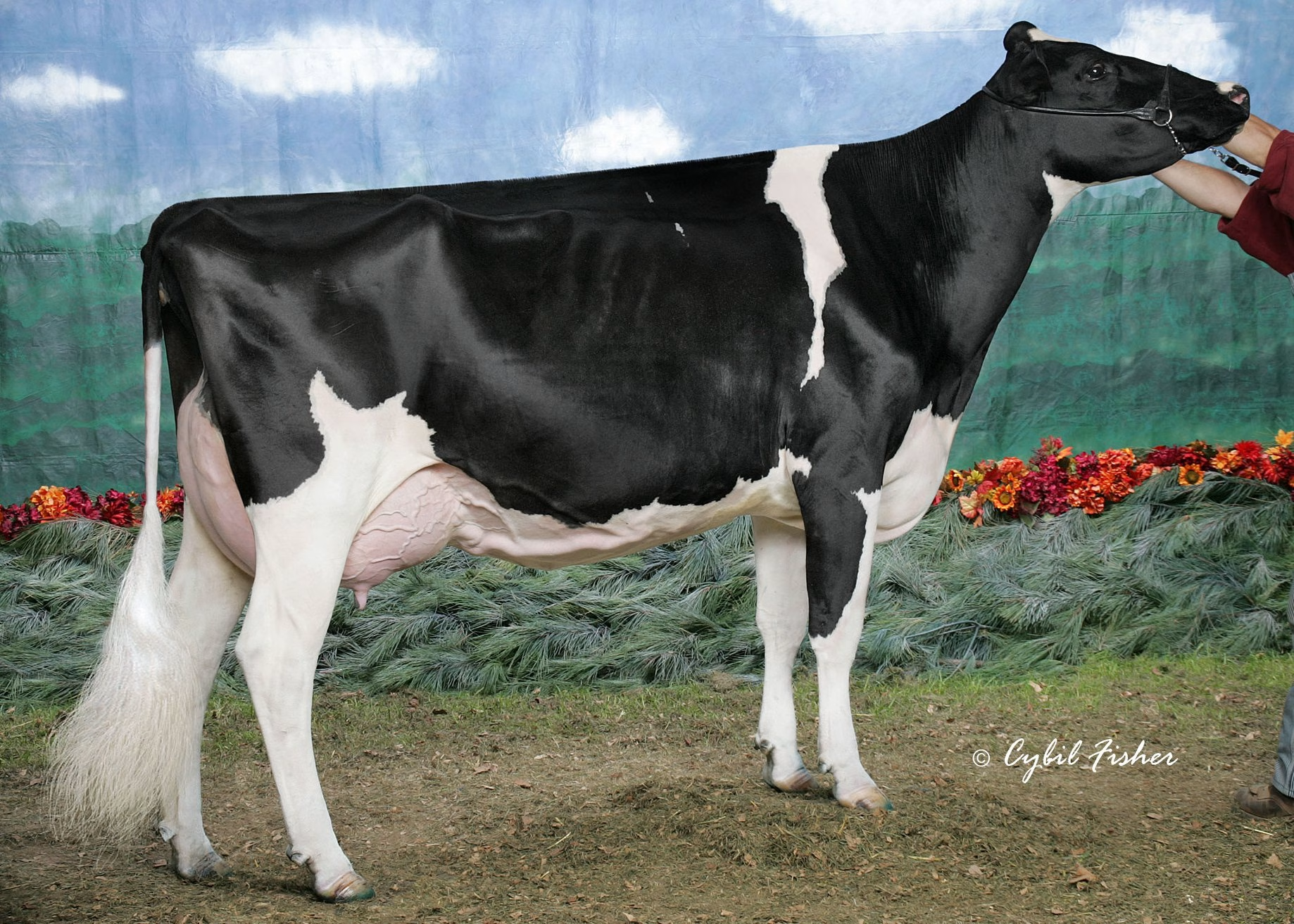

Intermediate Champion

Intermediate: FORTALE LAMBDA LOA – FERME FORTALE HOLSTEIN INC, SAINT-CHRISTOPHE-D’ARTHABASKA, QC

Reserve: BELFAST BELIEVE FANNY – BELFAST HOLSTEIN ENR, SAINT-PATRICE-DE-BEAURIVAGE, QC

HM: LYSEM LOYALL AUDE, BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC

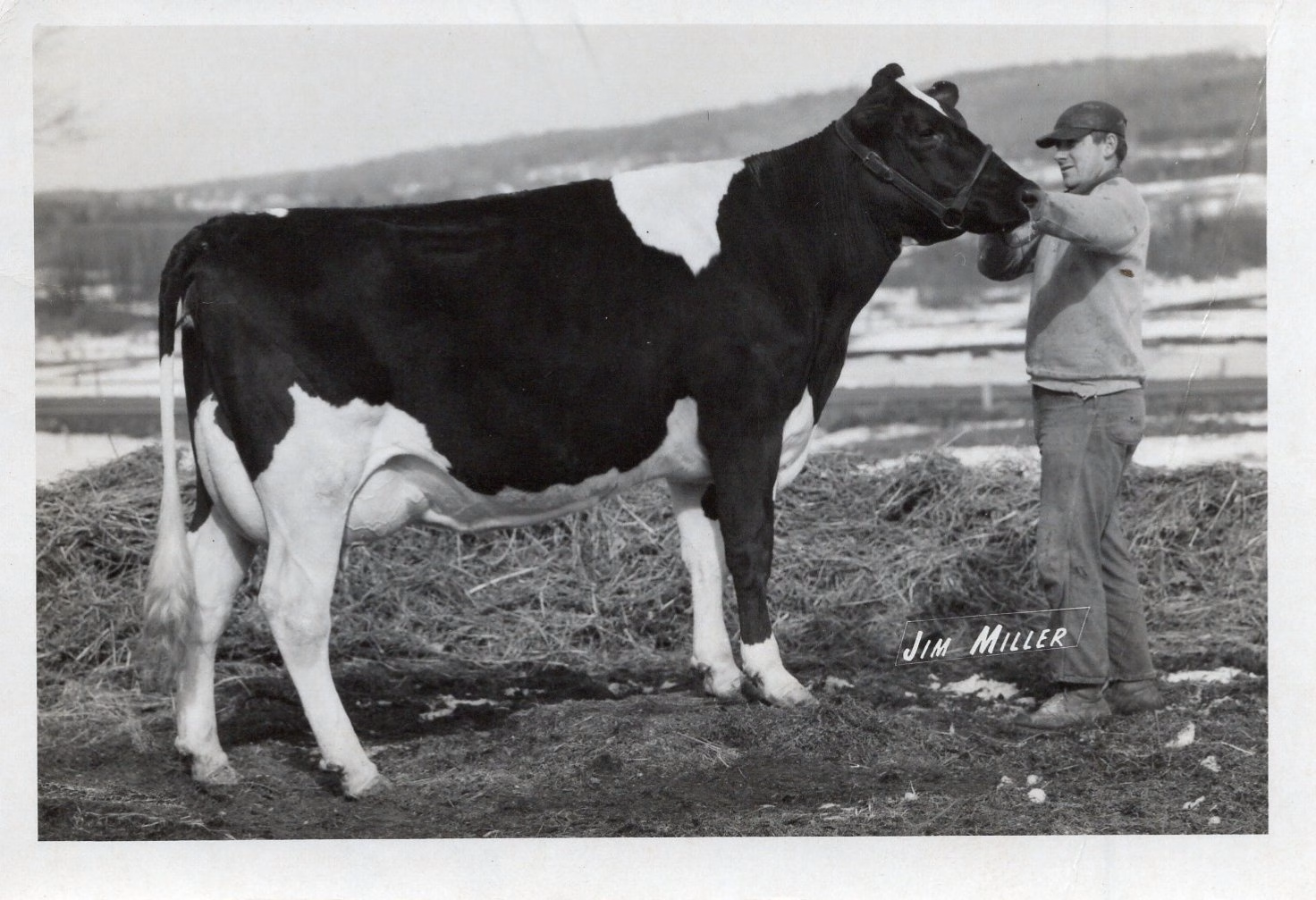

Junior Champion

Junior: REPA DRH JEMMA TATOO – FERME BEAUDOIN, MELANIE PARENTEAU, DURHAM-SUD, QC

Reserve: DUHIBOU EYE CANDY FANCY, – FERME DUHIBOU INC, ST. LAMBERT DE LAUZON, QC

HM: JM VALLEY SALUTE FIOLA – JM VALLEY HOLSTEIN, AMQUI, QC

Winter Calf

1st place Winter Calf

Quebec Spring Holstein Show 2025

FERME MILIBRO INC, LOUISE BLANCHET, MATHIEU BLANCHET, TINGWICK, QC

Née entre le 1er décembre 2024 et le 28 février 2025

- MILIBRO DETECTIVE ROSELEYLAH, HOCANF121956815

Propriété élevée

FERME MILIBRO INC, LOUISE BLANCHET, MATHIEU BLANCHET, TINGWICK, QC - CLOVIS MASTER REINE, HOCANF121690666

CLOVIS HOLSTEIN INC, SAINT-ALEXANDRE-DE-KAMOURASKA, QC - KINGSWAY LAMBDA HAPPY, HOCANF14799026

FERME JEAN-PAUL PETITCLERC & FILS INC, ST. BASILE, QC - BLONDIN ARMOUR LAUREATE, HOCANF121802185

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - FORTOISE ALTITUDE JESSY-RED, HOCANF121950298

FERME FORTOISE INC, SAINT-PIERRE-BAPTISTE, QC - LETARTE ROBERTA, HOCANF121806446

LETARTE HOLSTEIN, MIDDELBURG HOLSTEINS, SAINT-MICHEL-DE-BELLECHASSE, QC - KENNEBEC AMBROSE MCCAFÉ, HOCANF122019944

FERME SS KENNEBEC, SAINT-THÉOPHILE, QC - BLONDIN MASTER PILAR, HOCANF122060805

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - JM VALLEY AHSBY JAMAÏQUE, HOCANF122106054

JM VALLEY HOLSTEIN, AMQUI, QC - BARD ALLIGATOR ROMY, HOCANF121984182

FERME BARD INC, SAINTE-ANNE-DE-LA-POCATIÈRE, QC - PAYS BRULE BELLACIAO ALCOVE, HOCANF121892360

FERME PAYS BRULE INC, BAIE-DU-FEBVRE, QC - MICHDALE CAPTAIN PAMELA, HOCANF121989113

MICHAEL LEDUC, SAINT-JULIEN, QC - KENNEBEC BRUINS MOONLIGHT, HOCANF121804110

FERME SS KENNEBEC, SAINT-THÉOPHILE, QC - KENNEBEC LAMBDA ALASKA, HOCANF122019948

FERME LENIQUE INC, FERME VAL D’ESPOIR INC, SAINT-DENIS-DE-LA-BOUTEILLERIE, QC

Fall Calf

Née entre le 1er septembre 2024 et le 30 novembre 2024

1st place Fall Calf

Quebec Spring Holstein Show 2025

JM VALLEY HOLSTEIN, AMQUI, QC

- JM VALLEY SALUTE FIOLA, HOCANF121873550

Propriété-élevée

JM VALLEY HOLSTEIN, AMQUI, QC - REPA MARICO JEMMY ASHBY, HOCANF121755254

MARCO RODRIGUE & MARIE-CLAUDE MARCOUX, MELANIE PARENTEAU, SAINT-SIMON-LES-MINES, QC - FIREBURGER ARROW MAGESTEE, HOCANF121761127

FERME MILIBRO INC, FERME MYNAVIA, FREDERIC DUBOIS, TINGWICK, QC - JM VALLEY LAMBDA LIXIE, HOCANF121873551

ALEXANDRE GALLARD, ANTOINE BRACNAT, JM VALLEY HOLSTEIN - BARD MATCHLESS JOLEINE, HOCANF121646896

FERME BARD INC, SAINTE-ANNE-DE-LA-POCATIÈRE, QC - PREROSS ALLIGATOR LUCILLE, HOCANF121359562

FERME VERT D’OR INC, STE. HELENE, QC - PETITCLERC AMBROSE KASHMIR, HOCANF121919616

FERME JACOBS INC, CAP SANTE, QC - SELEXIE CASSY WARRIOR, HOCANF121971889

FERME SELEXIE, HAM-NORD, QC - LETARTE BUY ME A BOAT, HOCANF121806441

LETARTE HOLSTEIN, SAINT-MICHEL-DE-BELLECHASSE, QC - ELIANE LAMBDA ROCHE, HOCANF121426929

ANDRE DION, LÉVIS, QC - JM VALLEY SALUTE JACKIE, HOCANF121873549

FERME GILARO, JONQUIERE, QC - KARNVIEW MASTER JOLENE, HOCANF15047204

AJ GENETICS, EMBRUN, ON - JACOBS MAXIMUM LASH, HOCANF121808930

FERME JACOBS INC, CAP SANTE, QC - ELIANE AMBROSE FYDGIE, HOCANF121426927

ANDRE DION, LÉVIS, QC - KENNEBEC LOYALL DOOLY’S, HOCANF121609814

FERME SS KENNEBEC, SAINT-THÉOPHILE, QC - CHALUKA SIDEKICK KATARINA, HOCANF121833487

FERME CHAREST 2001 INC, SAINT-ALEXANDRE-DE-KAMOURASKA, QC - TIMICK HEARTLAND LARAMIE, HOCANF121712920

TIMICK HOLSTEIN, SAINT-RÉMI-DE-TINGWICK, QC - DREAMRIDGE SWEETART, HOCANF13863753

BLACKADDAR FARMS, DAVE & BONNIE BERGERON, IAN DINGWALL, CHARLOTTETOWN, PE - BAY MASTER CRANBERRY, HOCANF121826491

FERME GILARO, JONQUIERE, QC - NELSONDALE EYE CANDY VANILLA, HOCANF121777768

NELSONDALE FARM S.E.N.C, MELBOURNE, QC

Summer Yearling

1st place Summer Yearling

Quebec Spring Holstein Show 2025

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC

Née entre le 1er juin 2024 et le 31 août 2024

- BLONDIN DRAX HORIZON, HOCANF121802099

Propriété élevée

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - SELEXIE MARISOLA GRINCH, HOCANF121694508

FERME SELEXIE, HAM-NORD, QC - JANGIE MASTER KOKODIA, HOCANF121799938

FERME JANGIE 2016 INC, SAINTE-CHRISTINE, QC - ELIANE BREAKSHOT LORNA, HOCANF121426926

ANDRE DION, LÉVIS, QC - BLONDIN DRAX LAKAI, HOCANF121802075

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - ROTALY DREAM COLLETTE, HOCANF121544234

BLONDIN SIRES, FERME BLONDIN, FLEURY HOLSTEIN, SAINT-PLACIDE, QC - JACOBS ALLIGATOR LOVER, HOCANF14836942

FERME GILLETTE INC, FERME JACOBS INC, T-WAVE HOLSTEINS, EMBRUN, ON - MILIBRO PARFECT PRESTIGIEUSE, HOCANF121761122

FERME MILIBRO INC, TINGWICK, QC - SUCCESS SALUTE HYPE, HOCANF121573919

LOUIS-PHILIPPE HUDON & VIRGINIE BILODEAU, SAINT-HENRI-DE-LÉVIS, QC - SELEXIE CLARA DIRECT, HOCANF121694513

FERME SELEXIE, HAM-NORD, QC - BESLEA KINGBOY LET ER RIP, HOCANF14907719

SKIPWELL FARMS INC, AYLMER, ON - LETARTE DIRECT HADLEY, HOCANF121806424

LETARTE HOLSTEIN, SAINT-MICHEL-DE-BELLECHASSE, QC - PETITCLERC TATOO BROOK, HOCANF121778396

FERME MARICAN INC, SAINTE-HÉNÉDINE, QC - VERTDOR ALPHA MITZY, HOCANF121359526

FERME VERT D’OR INC, STE. HELENE, QC - PETITCLERC BREAKSHOT TUNA, HOCANF121778397

HEDWAY FARMS, KNONAUDALE FARMS INC, BEACHBURG, ON - HUBELLE ALLIGATOR SAMANTHA, HOCANF121853312

RAEBURN HOLSTEINS, RAECROFT FARM G.P., HOWICK, QC - DURHAM LAMBDA CARAMILK, HOCANF121344767

FERME MARICAN INC, FERME STEEV LAROSE INC, SAINTE-HÉNÉDINE, QC

Spring Yearling

Née entre le 1er mars 2024 et le 31 mai 2024

- KARNVIEW EYE CANDY ANASTASIA, HOCANF15047151

AJ GENETICS, EMBRUN, ON - LANORMANDE D-LAMBDA CORALIE, HOCANF121282610

Propriété-élevée

FERME LANORMANDE INC, VICTORIAVILLE, QC - VELTHUIS BULLSEYE ONEIDA, HOCANF14860268

VELTHUIS FARMS LTD, OSGOODE, ON - BAY MASTER HIGH TIDE, HOCANF15042506

BAY HOLSTEINS, MAURANNE HEBERT, MURRAY SIDING, NS - ELIANE JORDY RYNA, HOCANF121426921

ANDRE DION, LÉVIS, QC - RICAGRI F ARROW AYOYE, HOCANF121671734

FERME RICAGRI INC, FREDERIC DUBOIS, LECLERCVILLE, QC - BLONDIN CHEERFUL LUST-RED, HOCANF121589114

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - COBEQUID WARRIOR RAE, HOCANF15042493

PIERRE BOULET, MONTMAGNY, QC - JACOBS TARMAC CONSTANCE, HOCANF121468252

FERME JACOBS INC, CAP SANTE, QC - JACOBS ALPHA CANAM, HOCANF121468236

FERME JACOBS INC, CAP SANTE, QC - LETARTE MASTER YUZU, HOCANF121347989

LETARTE HOLSTEIN, SAINT-MICHEL-DE-BELLECHASSE, QC - KENNEBEC TATOO NORA, HOCANF121609769

FERME SS KENNEBEC, SAINT-THÉOPHILE, QC - SELEXIE BEAUTY MAXIMUM, HOCANF121694499

FERME SELEXIE, HAM-NORD, QC - PANDA LAMBDA DAISY, HOCANF121649731

FERME PANDA INC, WARWICK, QC - PETITCLERC CHIEF TEXAS, HOCANF121778381

CLOVIS HOLSTEIN INC, FERME CHAREST 2001 INC, FERME VERT D’OR INC, SAINT-ALEXANDRE-DE-KAMOURASKA, QC - TIMICK PURSUIT DAYTONA, HOCANF121712912

TIMICK HOLSTEIN, SAINT-RÉMI-DE-TINGWICK, QC

Winter Yearling

Née entre le 1er décembre 2023 et le 29 février 2024

- DUHIBOU EYE CANDY FANCY, HOCANF121623781

Propriété élevée

FERME DUHIBOU INC, ST. LAMBERT DE LAUZON, QC - GENO ARMADA KILLIAN, HOCANF121642085

FERME GENO INC, SAINT-MARC-DES-CARRIÈRES, QC - D-RAY VANGUARD ZOEGARDE, HOCANF121535389

D-RAY HOLSTEIN, FERME MILIBRO INC, VICTORIAVILLE, QC - ROCHELET SIDEKICK POMKOU, HOCANF121125234

FERME PANDA INC, FERME ROCHELET INC, WARWICK, QC - ELIANE AIRCRAFT RAMY, HOCANF121426919

ANDRE DION, LÉVIS, QC - REPA JOURNEY LEGEND, HOCANF120266108

MELANIE PARENTEAU, SAINT-JEAN-BAPTISTE, QC - SELEXIE BRITNEY WINTER, HOCANF121694474

FERME SELEXIE, HAM-NORD, QC - VELTHUIS BULLSEYE OCEANIA, HOCANF14860226

VELTHUIS FARMS LTD, OSGOODE, ON - COBEQUID ALTITUDE DELPHI, HOCANF14858504

COBEQUID HOLSTEINS, LOWER DEBERT, NS - KENNEBEC MASTER BETTY, HOCANF121609774

FERME SS KENNEBEC, SAINT-THÉOPHILE, QC - PETITCHENE LEMAGIC RAYONNANTE, HOCANF121305670

FERME DU PETIT CHENE, SAINT-IGNACE-DE-LOYOLA, QC

Fall Yearling

Née entre le 1er septembre 2023 et le 30 novembre 2023

- REPA DRH JEMMA TATOO, HOCANF120266103

Propriété-élevée

FERME BEAUDOIN, MELANIE PARENTEAU, DURHAM-SUD, QC - DUHIBOU EYE CANDY FULLKY, HOCANF121456252

FERME DUHIBOU INC, ST. LAMBERT DE LAUZON, QC - CERPOLAIT HANIKO SUGAR, HOCANF121545564

FERME CERPOLAIT S.E.N.C, SAINT-AIMÉ, QC - SELEXIE ROSALINA MASTER, HOCANF121444980

FERME SELEXIE, HAM-NORD, QC - SELEXIE CARAMELDORÉ DETECTIVE, HOCANF121444983

FERME SELEXIE, HAM-NORD, QC - SELEXIE CIBELLA DETECTIVE, HOCANF121444971

FERME SELEXIE, HAM-NORD, QC - MILIBRO MASTER ROSELOLA, HOCANF121535377

FERME MILIBRO INC, LOUISE BLANCHET, MATHIEU BLANCHET, TINGWICK, QC - GOLDEN-OAKS-I ALTITUDE IREINE, HOCANF120723541

STEVE BOULET, SAINTE-BRIGIDE-D’IBERVILLE, QC - LEHOUX ALLIGATOR JAKARTA, HOCANF121281651

B. LEHOUX & FILS INC, SAINT-ELZÉAR, QC - REPA MARICO JENNYABEL ASHBY, HOCANF121397131

MARCO RODRIGUE & MARIE-CLAUDE MARCOUX, MELANIE PARENTEAU, SAINT-SIMON-LES-MINES, QC - BARD DROPBOX JOLYGOLD, HOCANF121646848

FERME BARD INC, SAINTE-ANNE-DE-LA-POCATIÈRE, QC - ELIANE APERO RYANNA, HOCANF121426914

ANDRE DION, LÉVIS, QC - MARICAN EYE CANDY SANDRIA, HOCANF121566460

FERME MARICAN INC, SAINTE-HÉNÉDINE, QC - RAEBURN LADY HAS IT ALL, HOCANF121096703

RAECROFT FARM G.P., HOWICK, QC

Junior Breeder

- FERME SELEXIE

HAM-NORD, QC - BLONDIN SIRES, FERME BLONDIN

SAINT-PLACIDE, QC - ANDRE DION

LÉVIS, QC

Junior Exhibitor

- SELEXIE / FRANCE OUELLET (SELEXIE)

HAM-NORD, QC - FERME BLONDIN (BLONDIN)

SAINT-PLACIDE, QC - REPA HOLSTEINS ET MÉLANIE PARENTEAU / MÉLANIE PARENTEAU (REPA)

ST-JEAN-BAPTISTE, QC

Summer Two Year Old

Née entre le 1er juin 2023 et le 31 août 2023

- BLONDIN EYE CANDY SALANA, HOCANF121397068

Propriété-élevée

Meilleur Pis

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - KNONAUDALE MYSTIC DREAM, HOCANF14593984

KNONAUDALE FARMS INC, CRYSLER, ON

Spring Two Year Old

Née entre le 1er mars 2023 et le 31 mai 2023

- LYSEM LOYALL AUDE, HOCANF121178302

Meilleur Pis

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - SELEXIE LAURIZE MASTER, HOCANF121444936

Propriété-élevée

FERME SELEXIE, HAM-NORD, QC - MABEL LAMBDA LOVE STORY, HOCANF121299057

FERME YVON SICARD, SAINT-JUSTIN, QC - ROYALWATER CAMARO OLIVIA, HOCANF14540482

FERME BLONDIN, JEAN-PHILIPPE PROULX, JM VALLEY HOLSTEIN, SAINT-PLACIDE, QC - JACOBS VICTOR VIOLETTE, HOCANF121251460

CRACKHOLM HOLSTEINS, RICHMOND, QC - MAGOLAIT ALPHA MADISON, HOCANF121226055

FERME MAGOLAIT INC, MAGOG, QC - ROTALY MASTER CREED, HOCANF121154915

HY-HAVEN GENETIQUE INC, SAINTE-HÉLÈNE-DE-KAMOURASKA, QC - JACOBS ASHTON BREE, HOCANF14476568

CRACKHOLM HOLSTEINS, RICHMOND, QC - SICY LAMBDA ANGE, HOCANF121395970

FERME BLONDIN, FERME GLAUSER & FILS INC, FERME YVON SICARD, SAINT-PLACIDE, QC - BLONDIN LAMBDA LAZERBEAM, HOCANF121397008

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - DELCREEK BANGARANG, HOCANF14580316

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - LESPEREE PARFECT SUZIE, HOCANF121386841

FERME L’ESPEREE INC, SAINT-HENRI-DE-LÉVIS, QC - KMC DESTINATION LIA-LIANE, HOCANF121250588

FERME KMC, VAL-BRILLANT, QC - PREMIUM TATOO ANABELLE, HOCANF121425545

FRANCIS MORNEAU, MELBOURNE, QC - MELBORO ETESIAN ROXSTAR, HOCANF121425550

FRANCIS MORNEAU, MELBOURNE, QC - CERPOLAIT HANIKO TASTY, HOCANF120918784

CRACKHOLM HOLSTEINS, RICHMOND, QC - LESBERTRAND LEMAGIC BILING, HOCANF121959798

GEORGES BERTRAND, SAINT-POLYCARPE, QC - FAMIPAGE BRYSON P LIV, HOCANF121162967

FERME FAMIPAGE INC, SAINT-LOUIS-DE-GONZAGUE, QC - BONACCUEIL CHARME LAMBDA, HOCANF121341942

A. & R. BOULET INC, ST-FRANÇOIS-DE-LA-RIVIÈRE-DU-SUD, QC

Winter Two Year Old

Née entre le 1er décembre 2022 et le 28 février 2023

- JACREST DOC LISA, HOCANF14642475

Championne meilleur pis

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - GOLDENFLO LEIGHSIDE CHEERFUL, HOCANF14592219

FERME BLONDIN, JEAN-PHILIPPE PROULX, JM VALLEY HOLSTEIN, LONDON DAIRY FARMS, SAINT-PLACIDE, QC - PIERSTEIN LAMBDA MICKEY, HOCANF121217310

Propriété élevée

PIERRE BOULET, MONTMAGNY, QC - BENJO DYNAMITE DOLLARSTAR, HOCANF120334978

FERME BENJO 2003 INC, ST. ZEPHIRIN, QC - CNOSSOME ENERGY AVALYNN, HOCANF14470253

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - KNONAUDALE MIRANDA LAMBERT, HOCANF14593941

KNONAUDALE FARMS INC, CRYSLER, ON - FAMIPAGE ALPHA POPCORN, HOCANF121162963

FERME FAMIPAGE INC, SAINT-LOUIS-DE-GONZAGUE, QC - BESLEA ALLYN HG LAMBDA CAVIAR, HOCANF14456573

BESLEA FARMS LTD, YARKER, ON - KMC LAMBDA JAKE, HOCANF121250584

FERME KMC, VAL-BRILLANT, QC - MADY DESTINATION DARLENE, HOCANF120962811

FERME MADY INC, ST-VALÉRIEN, QC - ROSBLAIS TATOO MARCELLE CLARA, HOCANF121273888

FERME ROSAIRE BLAIS ET FILS INC, ST. ISIDORE VILLAGE, QC

Fall Two Year Old

Née entre le 1er septembre 2022 et le 30 novembre 2022

- PIERSTEIN LAMBDA GINAMARIA, HOCANF121217355

Propriété élevée

PIERRE BOULET, MONTMAGNY, QC - JACOBS TATOO BRANELLE, HOCANF120983093

Meilleur Pis

HY-HAVEN GENETIQUE INC, SAINTE-HÉLÈNE-DE-KAMOURASKA, QC - BLONDIN ALPHA CALLIE, HOCANF121174743

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - MILIBRO PERENNIAL KELLYA, HOCANF121257031

FERME MILIBRO INC, TINGWICK, QC - KNONAUDALE TOXIC, HOCANF14593938

KNONAUDALE FARMS INC, CRYSLER, ON - KNONAUDALE MEGAHOT, HOCANF14593936

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - CLOVIS KING DOC BIANCA, HOCANF121065901

CLOVIS HOLSTEIN INC, SAINT-ALEXANDRE-DE-KAMOURASKA, QC - PIERSTEIN ALTITUDE AUSTRALIA, HOCANF121217328

PIERRE BOULET, MONTMAGNY, QC - BONACCUEIL MARBY FUEL, HOCANF121264577

A. & R. BOULET INC, ST-FRANÇOIS-DE-LA-RIVIÈRE-DU-SUD, QC - PETITCHENE CHIEF LAURA, HOCANF121305630

FERME DU PETIT CHENE, SAINT-IGNACE-DE-LOYOLA, QC - DREAMRIDGE EUPHORIA, HOCANF13863752

DAVE & BONNIE BERGERON, STRAITSIDE HOLSTEINS, HAMMOND, ON

Junior Three Year Old

Née entre le 1er mars 2022 et le 31 août 2022

- PIERSTEIN LAMBDA GINELLE, HOCANF121217353

Propriété-élevée

Meilleur Pis

PIERRE BOULET, MONTMAGNY, QC - BONACCUEIL ALIBI LAMBDA, HOCANF120729352

A. & R. BOULET INC, ST-FRANÇOIS-DE-LA-RIVIÈRE-DU-SUD, QC - WINRIGHT DOORMAN BELLAGIO, HOCANF14341947

KAYMANOR HOLSTEINS, STRATFORD, ON - LYSEM AVENGER HARPE, HOCANF120786250

FERME LEVASSEUR, FERME LYSEM S.E.N.C, GHYSLAIN DEMERS, TROIS-RIVIERES, QC

Senior Three Year Old

Née entre le 1er septembre 2021 et le 28 février 2022

- FORTALE LAMBDA LOA, HOCANF120844848

Propriété élevée

Meilleur Pis

Championne Intermédiaire Propriété-Élevée

Championne Intermédiaire

FERME FORTALE HOLSTEIN INC, SAINT-CHRISTOPHE-D’ARTHABASKA, QC - BELFAST BELIEVE FANNY, HOCANF120793719

Championne Intermédiaire de réserve

BELFAST HOLSTEIN ENR, SAINT-PATRICE-DE-BEAURIVAGE, QC - DESNETTE LOUISE CRUSH, HOCANF120941218

DESNETTE HOLSTEIN, WARWICK, QC - REDBRIDGE DOC WILMA, HOCANF13691182

PIERRE BOULET, MONTMAGNY, QC - FAMIPAGE LEGEND BARABAS, HOCANF120922735

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - BONACCUEIL ROSEMARIE DOC, HOCANF120729247

A. & R. BOULET INC, ST-FRANÇOIS-DE-LA-RIVIÈRE-DU-SUD, QC - JACOBS BAROLO CAZA, HOCANF120600974

FERME JACOBS INC, CAP SANTE, QC - JACOBS LAMBDA VACCIN, HOCANF120601012

FERME JACOBS INC, CAP SANTE, QC - KINGSWAY LAMBDA JASME, HOCANF120538996

B. LEHOUX & FILS INC, SAINT-ELZÉAR, QC - DESPERLE TITO DOC, HOCANF120601892

FERME LAPERLE ENRG, COATICOOK, QC - SICY SIDEKICK ALLO, HOCANF120886298

FERME YVON SICARD, GHYSLAIN DEMERS, SAINT-JUSTIN, QC - COMBALLES RITZI TORNADE, HOCANF120722791

FERME BLONDIN, FERME YVON SICARD, JEAN-PHILIPPE PROULX, SAINT-PLACIDE, QC - ROSBLAIS SIDEKICK GIFTE, HOCANF120713920

FERME ROSAIRE BLAIS ET FILS INC, ST. ISIDORE VILLAGE, QC - FAMIPAGE AVENGER MUSCADE, HOCANF120922743

FERME FAMIPAGE INC, SAINT-LOUIS-DE-GONZAGUE, QC - SWEETVIEW CHIEF HEART OF GOLD, HOCANF120664942

SWEETVIEW HOLSTEIN, AYER’S CLIFF, QC - MILIBRO LAMBDA KELLYANNY, HOCANF120807525

FERME MILIBRO INC, TINGWICK, QC - BERGITTE LAMBDA CUBA, HOCANF120660636

FERME PAQUETIERE INC, AMQUI, QC

Four Year Old

Née entre le 1er septembre 2020 et le 31 août 2021

- PIERSTEIN DEVOUR ROSHA, HOCANF120446696

Propriété-élevée

Meilleur Pis

PIERRE BOULET, MONTMAGNY, QC - JACOBS UNIX CARFUL, HOCANF120262310

FERME JACOBS INC, CAP SANTE, QC - LESPEREE LAMBDA SUMARA, HOCANF120731466

FERME L’ESPEREE INC, SAINT-HENRI-DE-LÉVIS, QC - SWEETVIEW KING DOC GELLO, HOCANF120403868

SWEETVIEW HOLSTEIN, AYER’S CLIFF, QC - HODGLYNN UNIX DIOR, HOCANF13742720

CRACKHOLM HOLSTEINS, FERME JACOBS INC, RICHMOND, QC - JACOBS LAMBDA RESCUE, HOCANF120684427

A. & R. BOULET INC, ST-FRANÇOIS-DE-LA-RIVIÈRE-DU-SUD, QC - COBEQUID DEVOUR SURI, HOCANF13810862

BAY HOLSTEINS, COBEQUID HOLSTEINS, MURRAY SIDING, NS - ROTALY ASHBY CAFE, HOCANF120300943

HY-HAVEN GENETIQUE INC, SAINTE-HÉLÈNE-DE-KAMOURASKA, QC - BONACCUEIL LIBIA RANDALL, HOCANF120131882

A. & R. BOULET INC, ST-FRANÇOIS-DE-LA-RIVIÈRE-DU-SUD, QC - LESFAUCHER ASHBY ROXY, HOCANF120177770

FERME JEAN-GUY FAUCHER & FILS INC, SAINTE-MARIE, QC

Five Year Old

Née entre le 1er septembre 2019 et le 31 août 2020

- JACOBS EXCALIBUR BAHAMAS, HOCANF111576115

Propriété élevée

Meilleur Pis

FERME JACOBS INC, CAP SANTE, QC - BONACCUEIL CHITA SIDEKICK, HOCANF120131826

A. & R. BOULET INC, ST-FRANÇOIS-DE-LA-RIVIÈRE-DU-SUD, QC - LESBERTRAND CRUSHABULL BIKI, HOCANF120427925

GEORGES BERTRAND, SAINT-POLYCARPE, QC - MACTALLA SIDEKICK RAYBAN, HOCANF13347397

CRACKHOLM HOLSTEINS, RICHMOND, QC - BULLSBROW H O BLATANT, HOCANF13657188

LOUIS-PHILIPPE HUDON & VIRGINIE BILODEAU, PIERRE BOULET, SAINT-HENRI-DE-LÉVIS, QC - JM VALLEY TROPIC LOUNA, HOCANF120317080

JM VALLEY HOLSTEIN, AMQUI, QC - VERTDOR ALLIGATOR MICKEY, HOCANF120073036

FERME VERT D’OR INC, STE. HELENE, QC - ROSBLAIS ATTORNEY CHRISTMAS, HOCANF111391796

FERME ROSAIRE BLAIS ET FILS INC, ST. ISIDORE VILLAGE, QC

Adult Cow

Née avant le 1er septembre 2019

- SICY IMPRESSION GABE, HOCANF110897892

Championne meilleur pis

FERME BLONDIN, JEAN-PHILIPPE PROULX, JM VALLEY HOLSTEIN, PIERRE BOULET, SAINT-PLACIDE, QC - ELM BEND GOOSE BUMP, HOCANF13309848

BLONDIN SIRES, FERME BLONDIN, SAINT-PLACIDE, QC - SWEETVIEW SIDEKICK VIPER, HOCANF111392201

Propriété élevée

SWEETVIEW HOLSTEIN, AYER’S CLIFF, QC - BELFAST SIDEKICK FANTASIA, HOCANF111244013

BELFAST HOLSTEIN ENR, SAINT-PATRICE-DE-BEAURIVAGE, QC - BONACCUEIL MOLY DEVOUR, HOCANF110284527

A. & R. BOULET INC, ST-FRANÇOIS-DE-LA-RIVIÈRE-DU-SUD, QC - MILIBRO DEVOUR LOVELY, HOCANF110538413

FERME MILIBRO INC, TINGWICK, QC

Production Cow

- SILVERMAPLE AWESOME FRANCE, HOCANF12647124

Championne meilleur pis

A. & R. BOULET INC, PIERRE BOULET, ST-FRANÇOIS-DE-LA-RIVIÈRE-DU-SUD, QC - MILIBRO UNIX PRISSILLA, HOCANF111111464

Propriété élevée

FERME MILIBRO INC, TINGWICK, QC

Join the Revolution!

Join the Revolution!